– 5 –

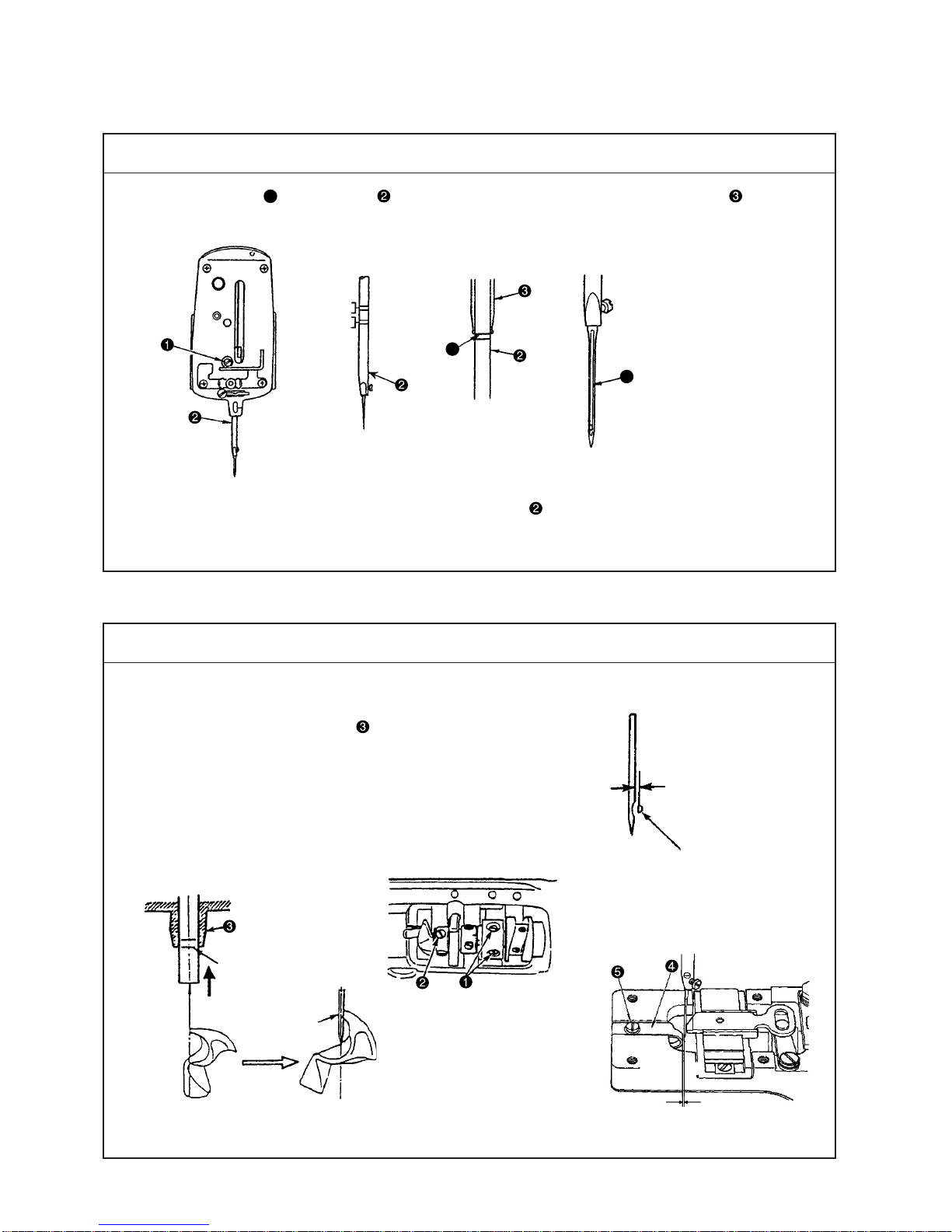

To adjust the timing of the travel of yoke slide , align the engraved

marks of loop positioning finger cam and loop positioning finger

triangular cam with the engraved mark of cam and looper sleeve

after the adjustment of the looper so that the engraved marks are in a

straight line. Then temporarily tighten the screws.

1. For the lateral-motion timing of yoke slide , the height of ascending

needle bar should be 4 to 7 mm when yoke slide begins to

travel from left to right.

For the longitudinal position of the cam, the center of the cam should

be aligned with the center of the positioning finger yoke slide.

2. Adjust loop positioning finger cam as described below:

Yoke slide has to travel backward linearly along the oblique side

of its triangular movement. For adjustment, the cam should be turned

in the reverse direction of rotation if the yoke slide travels backward

non-linearly along a convex curve, or in the direction of rotation if it

travels along a concave curve.

3. Adjust the longitudinal position of the yoke slide by moving loop

positioning finger cam in the lengthwise direction.

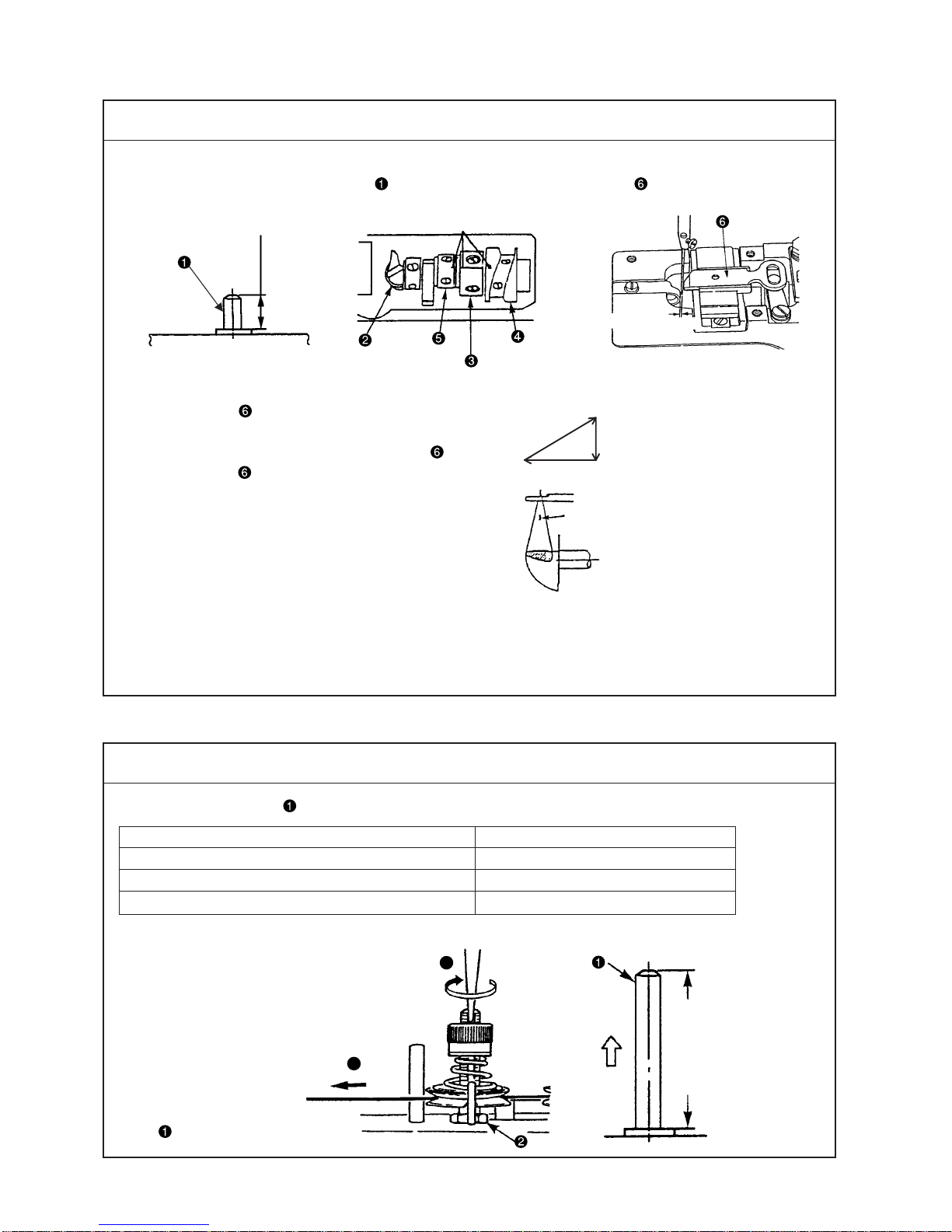

oIf loop positioning finger triangu-

lar cam begins to travel too late,

thread breakage, excess thread,

balloon stitches, and insufficient

tightness of the stitches will result.

Onthe contrary,if itbegins tomove

too early, the needle will come into

contact with yoke slide .

oIf loop positioning finger cam

begins to go back too early, the

retreat of yoke slide will become

like a swollen line and looper

will hook the thread twice.

oOn the other hand, if it begins to

retreat too late, its retreat will

become like a hollow line and the

needle will come into contact with

yoke slide .

oIf the longitudinal position of the

yoke slide is improper, looper

will hook the thread twice or the

needle will come into contact with

yoke slide .

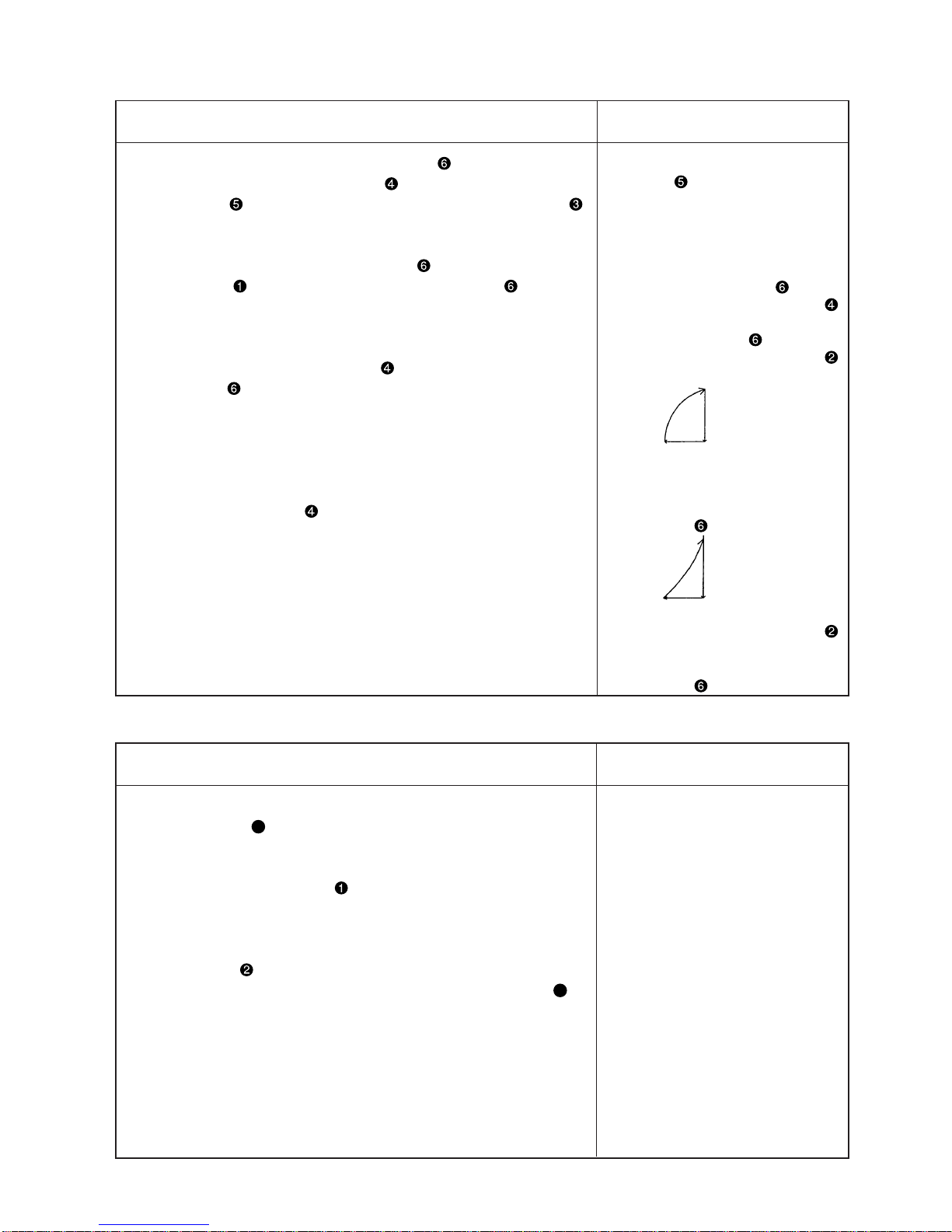

1. Turn the needle driving pulley as you draw the thread in the direction

of arrow mark Aand you will find a point at which the tension disc

on the tension post No. 2 release the thread. At this moment, the

standard distance from the top end of the needle bar bushing (upper)

to the top end of needle bar is 44 to 47 mm (in case of the needle

of TQ x 7, 54 to 57 mm)

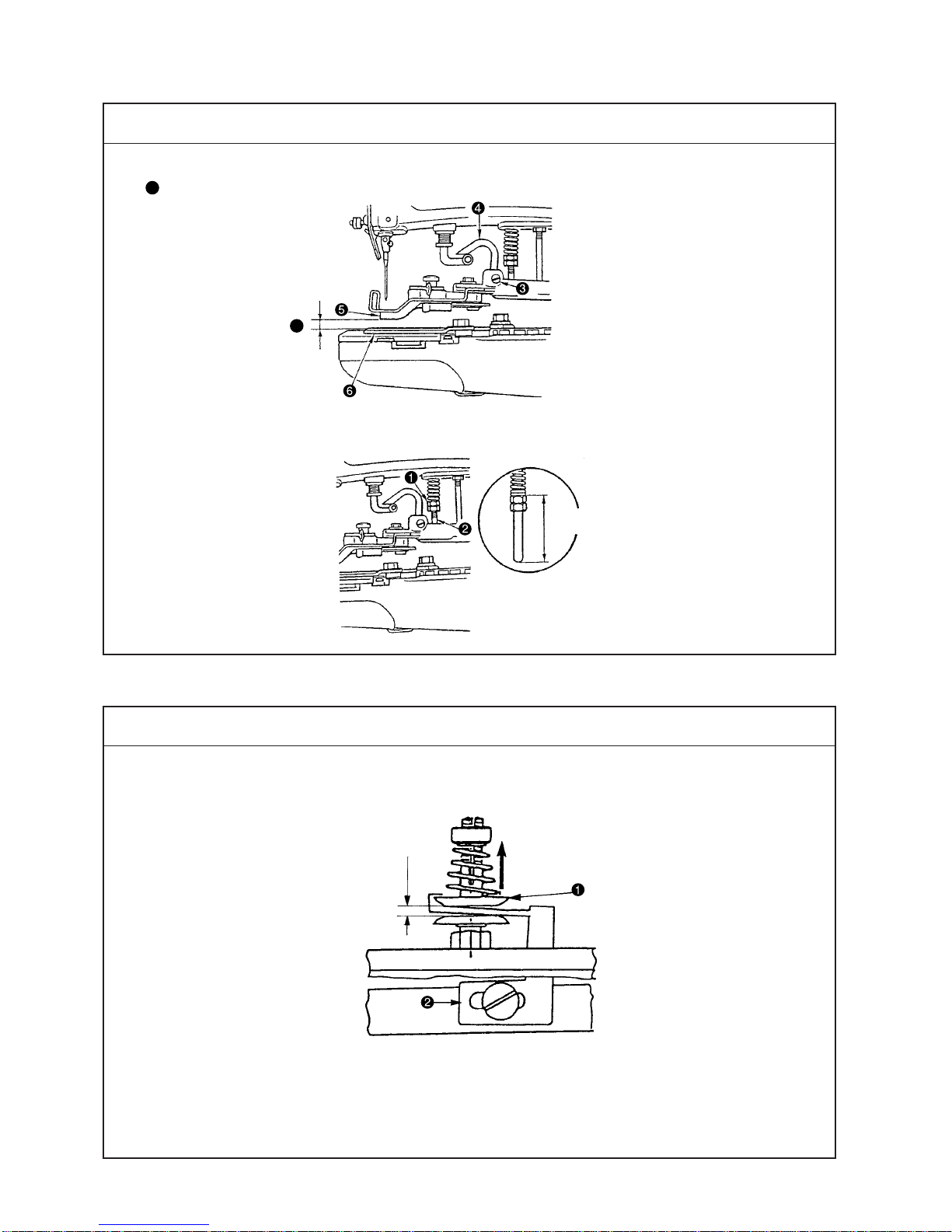

Perform the following adjustments especially when the

undermentioned troubles occur frequently.

2. Loosen nut , insert the blade of a screwdriver to the top slot of

the tension post No. 2 and turn it in the direction of arrow mark Bto

lowerthe height of the thread floating bar and in the opposite direction

to raise the height.

oIf the thread tension is released

too early, excess thread and/or

poor tightness of the stitches will

result.

oOn the other hand, if the timing of

the thread tension release is too

late, thread will break.

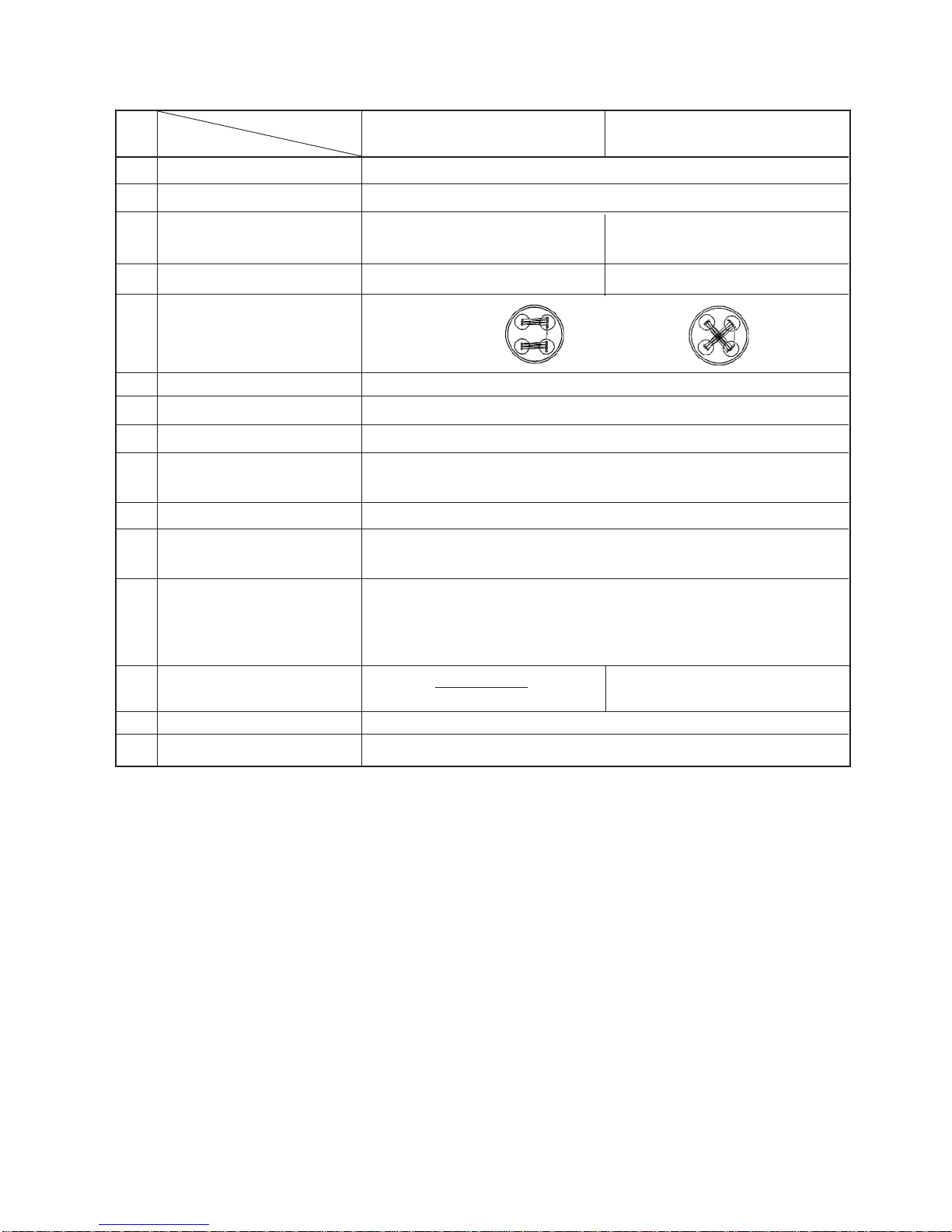

Yoke slide retreats

like a swollen line.

Yoke slide retreats

like a hollow line.

Adjustment Procedure Results of Improper Adjustment

Adjustment Procedure Results of Improper Adjustment