– 1 –

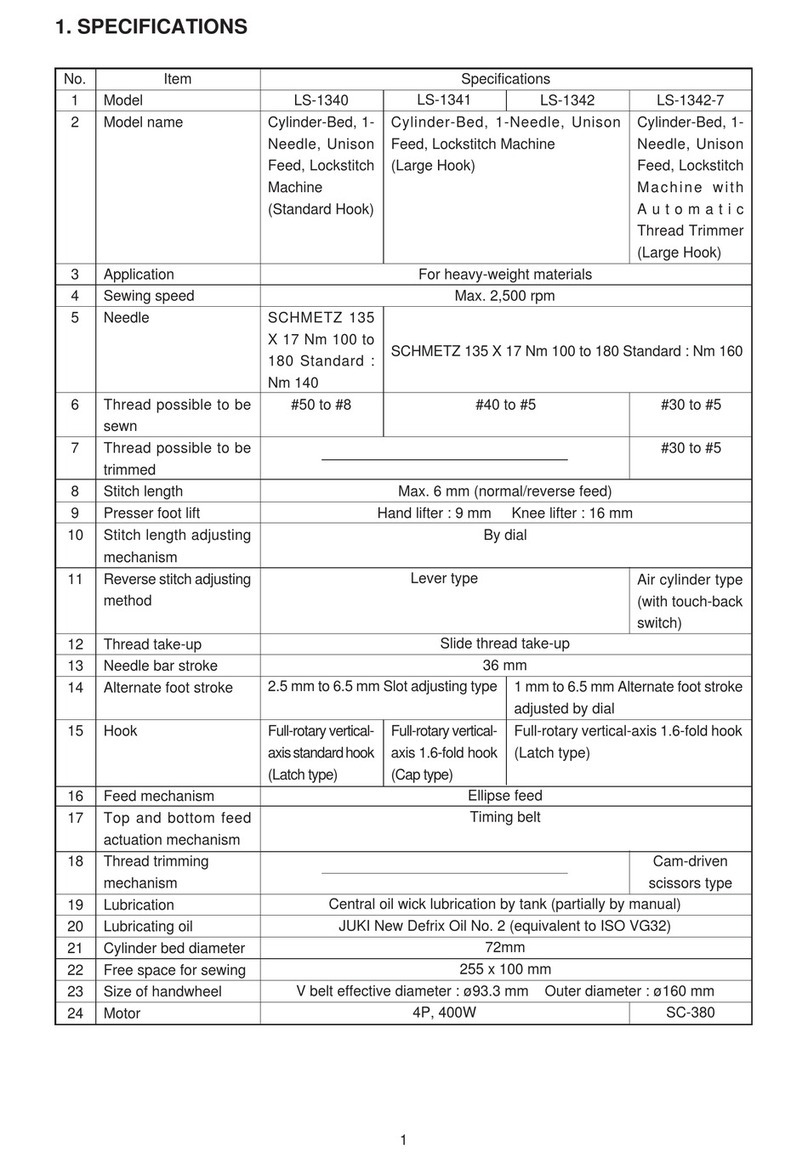

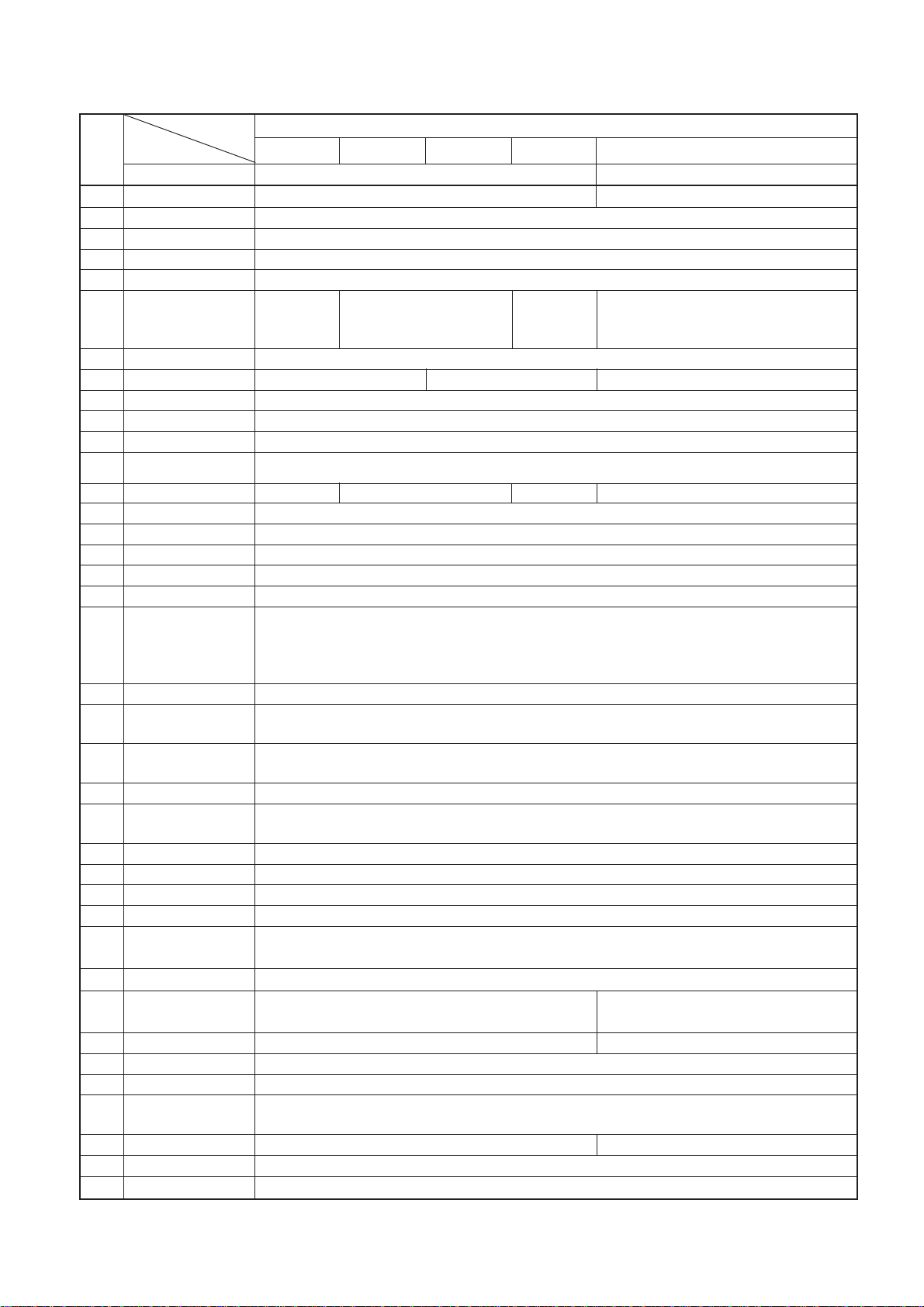

1. Specifications

(Caution) Grease type, refer to (3) Application of grease and Locktight

No. Application

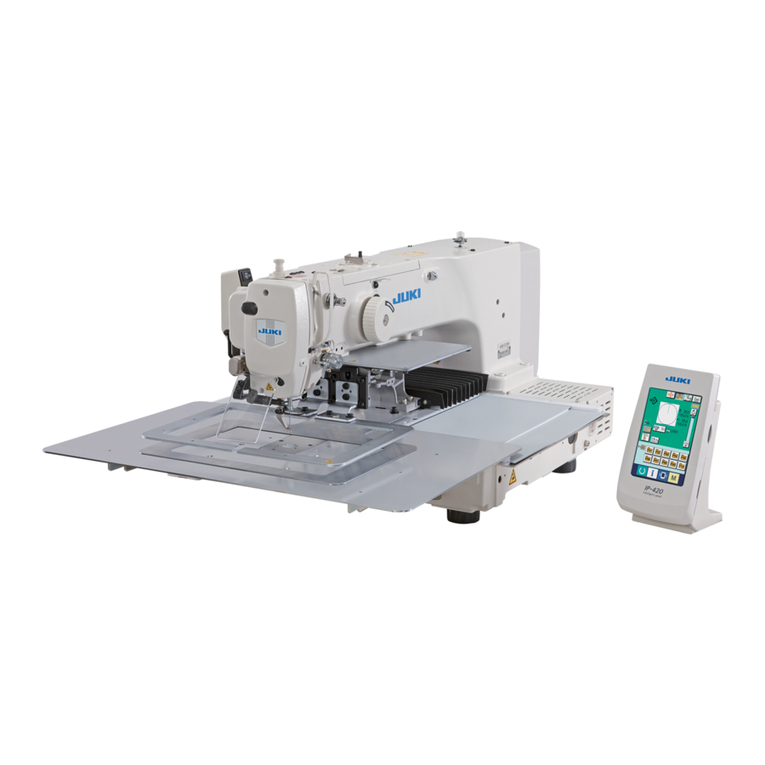

AMS-221ENSS AMS-221ENHS AMS-221ENHL AMS-221ENSL

AMS-221ENHS

Sub-class 2516 3020

1Sewing area

X-Direction (right, left) 250mm; Y-Direction (forward, backward) 160mm

X-Direction (right, left) 300mm; Y-Direction (forward, backward) 200mm

2 Max. sewing speed 2800sti/min (when sewing pitch is 3mm or less)

3 Stitch length 0.1 to 12.7mm (Min. resolution : 0.05mm)

4

Feed motion of feeding frame

intermittent feed (2-shaft drive by stepping motor)

5Needle bar stroke 41.2mm

S type: H type: S type: H type:

6Needle 134 No. 90 135 x 17 No. 110 134 No. 90 135 x 17 No. 110

(DP x 5#14) (DP x 17 #18) (DP x 5 #14) (DP x 17 #18)

7

Method to lift feeding frame

Air

8

Feeding frame shape

Right and left united Right and left separated Right and left united

9Lift of feeding frame Standard 25mm, Max. 30mm

10

Intermediate presser stroke

Standard 4mm (0 to 10mm)

11

Lift of intermediate presser

20mm

12 Standard 0 to 3.5mm (Max. 0 to 7.0mm)

13

Needle thread clamp device

S type H type S type H type

14

Needle thread tension

Active tension (electronic thread tension control mechanism)

15 Hook 2-fold semi-rotary hook

16 Lubrication Plane part: grease, hook part: minute volume lubrication (tank type)

17 Lubricating oil JUKI NEW Defrix oil No. 2 (equivalent to ISO VG32) (Lubrication system)

18 Grease 1.Penetration No. 2 lithium grease, 2. Templex N2, 3. Juki Grease A, 4. Juki Grease B (Caution)1.

Sewing machine, Media

19

Memory of pattern data

• Sewing machine :Max. 999 patterns (Max. 50,000 stitches/1pattern)/Max. 500,000 stitches

•Media :Max. 999 patterns (Max. 50,000 stitches/1pattern)/25million stitches

max.(CF card, 128M)/Approx. 50 milion stitches max. (CF card, 256M)

20

Temporary stop facility

Used to stop machine operation during a stitching cycle.

21 Enlarging/Reducing Allows a pattern to be enlarged or reduced on the X axis Y axis independently when sewing a pattern.

function 1% to 400% times (0.1% steps)

22 Enlarging/Reducing

Pattern enlargement / reduction can be done by increasing / decreasing either stitch length or the number of stitches.

method (When the pattern button is selected, the function available is only the adjustment of stitch length.)

23

Sewing speed limitations

200 to 2,800 sti/min (Scale : 100 sti/min steps)

Pattern No. selection method

(Sewing machine : 1 to 999, Media : 1 to 999)

25

No. of sheets counter

Up/Down method (0 to 9,999)

26 Sewing counter Up/Down method (0 to 9,999)

27

Bobbin thread counter

Up/Down method (0 to 9,999)

28 Memory back-up In case of a power interruption, the pattern being used will automatically be stored in memory.

Using jog keys, a 2nd origin (needle position after asewing cycle) can be set in the desired position within the sewing area

.

(The set 2nd origin is also stored in memory.)

30

Sewing machine moto

AC servo motor

W: 1,200mm L: 1,000mm H: 1,200mm W: 1,200mm L: 1,070mm H: 1,200mm

(Excluding thread stand) (Excluding thread stand)

32

Weight (gross weight)

201kg 210kg

33 Power consumption 700VA

34

Working temperature/humidity

Temperature: 5°C to 35°C, Humidity: 35 to 85% (no condensation)

Japan, JUS, export : 3-phase 200V to 240V (1-phase 100V/120V), China, Europe, general : 1-

phase 200V to 240V, Rating ±10%, 50/60Hz

36 Air pressure used Standard: 0.5 to 0.55MPa, Max. 0.55MPa Standard: 0.35 to 0.4MPa, Max. 0.55MPa

37 Air consumption 1.8dm3/min (ANR)

38

Needle highest position stop facility

After the completion if sewing, the needle can be brought up to its highest position.

Model name

Item

35

Supply voltage/frequency

24

Pattern selector facility

29

2nd origin setting facility

31 External dimensions

Intermediate presser

DOWN position variable