CONTENTS

1. Brief introduction ..................................................................................... 1

2. Mainspecications .................................................................................. 1

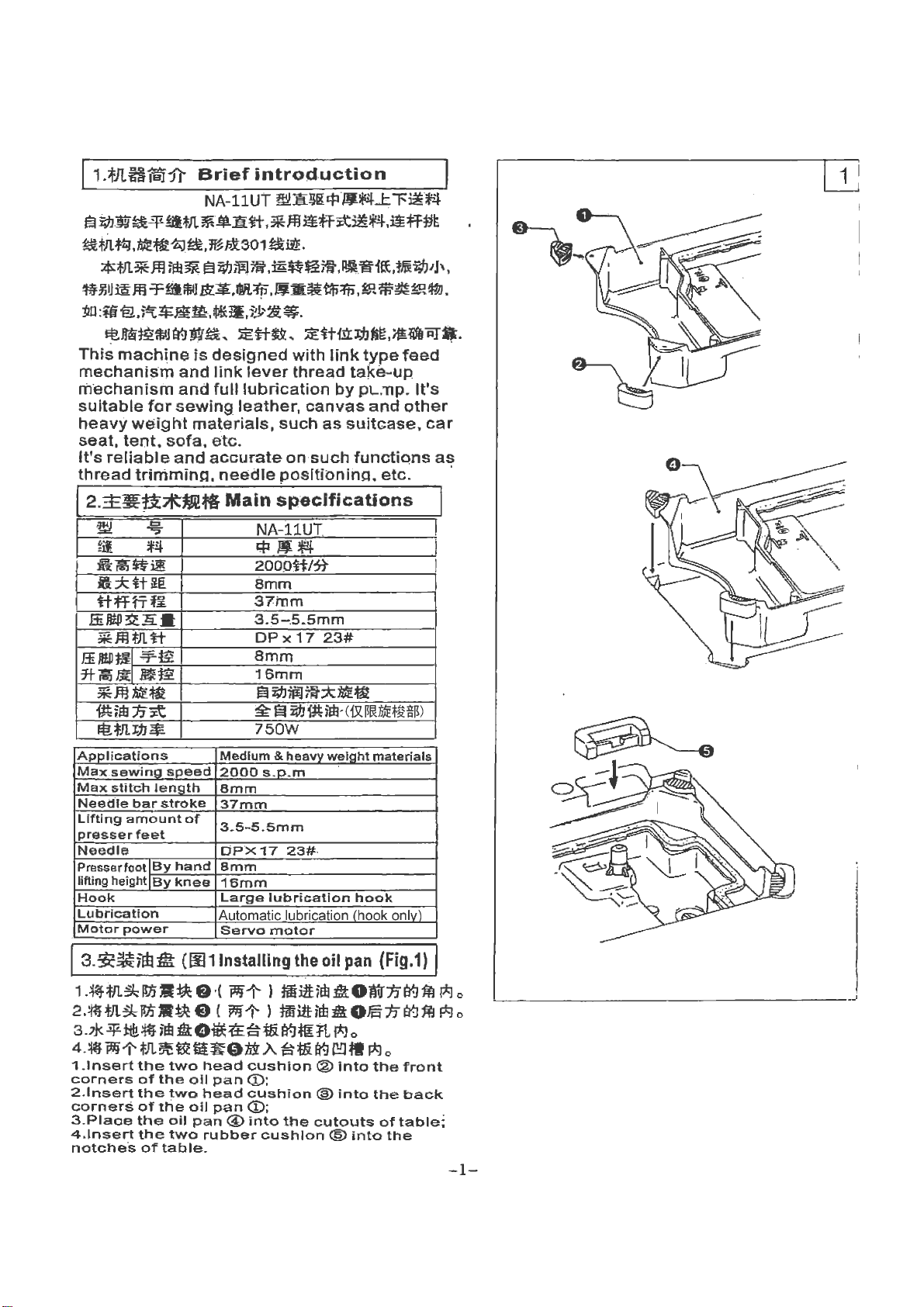

3.

Installing the oil pan

................................................................................. 1

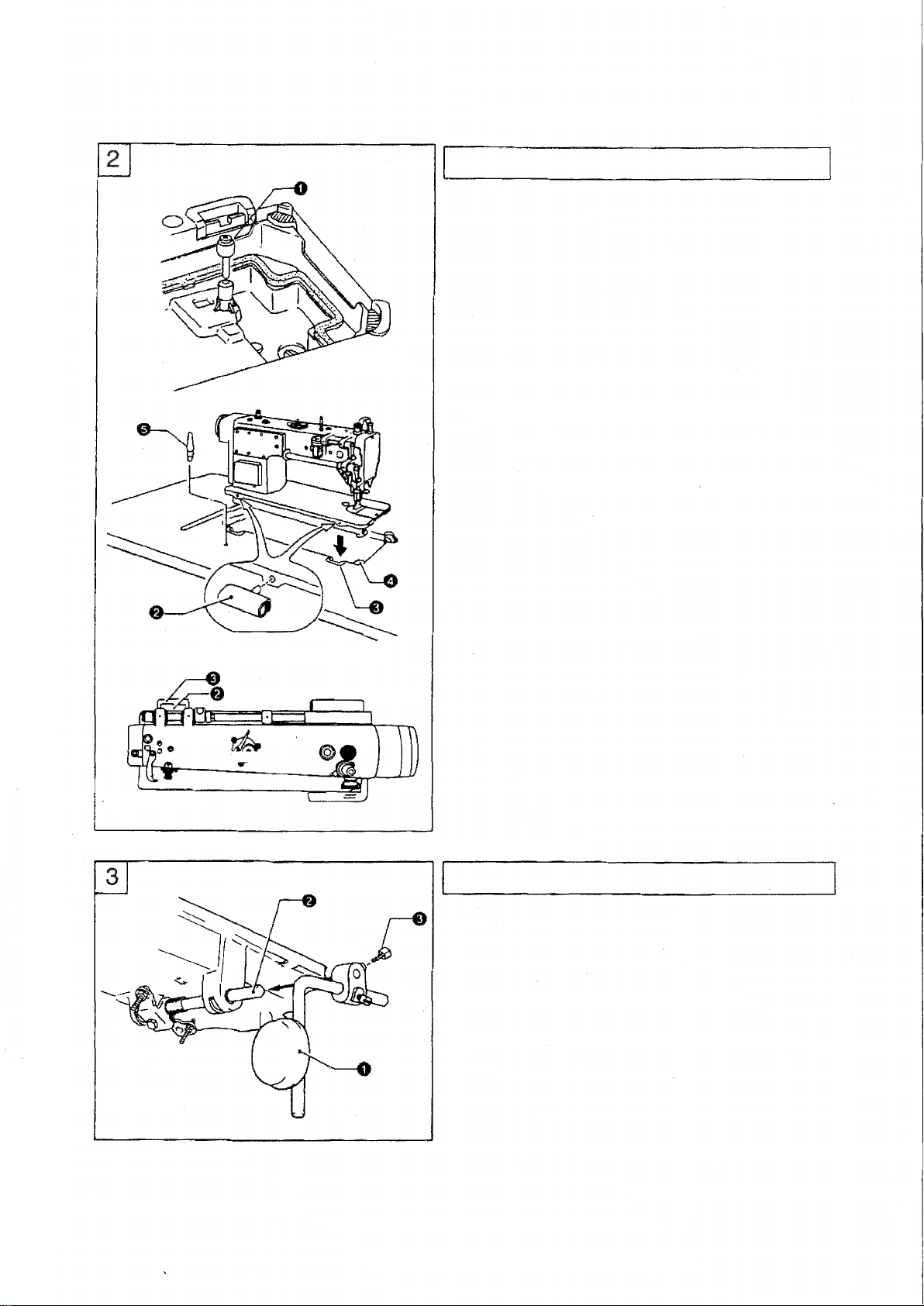

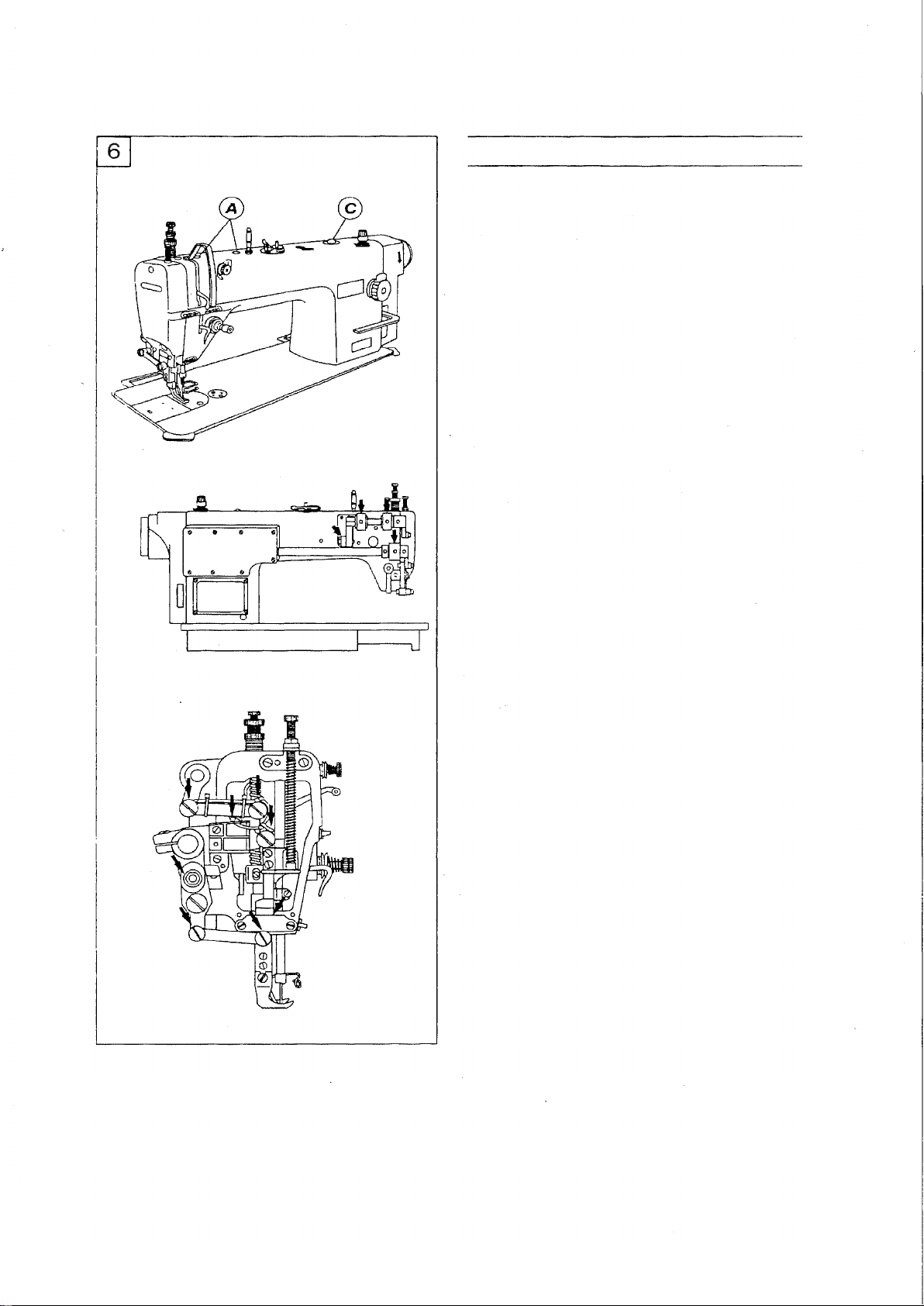

4. Installing the machine head .................................................................... 2

5. Installing the knee lifter assy .................................................................. 2

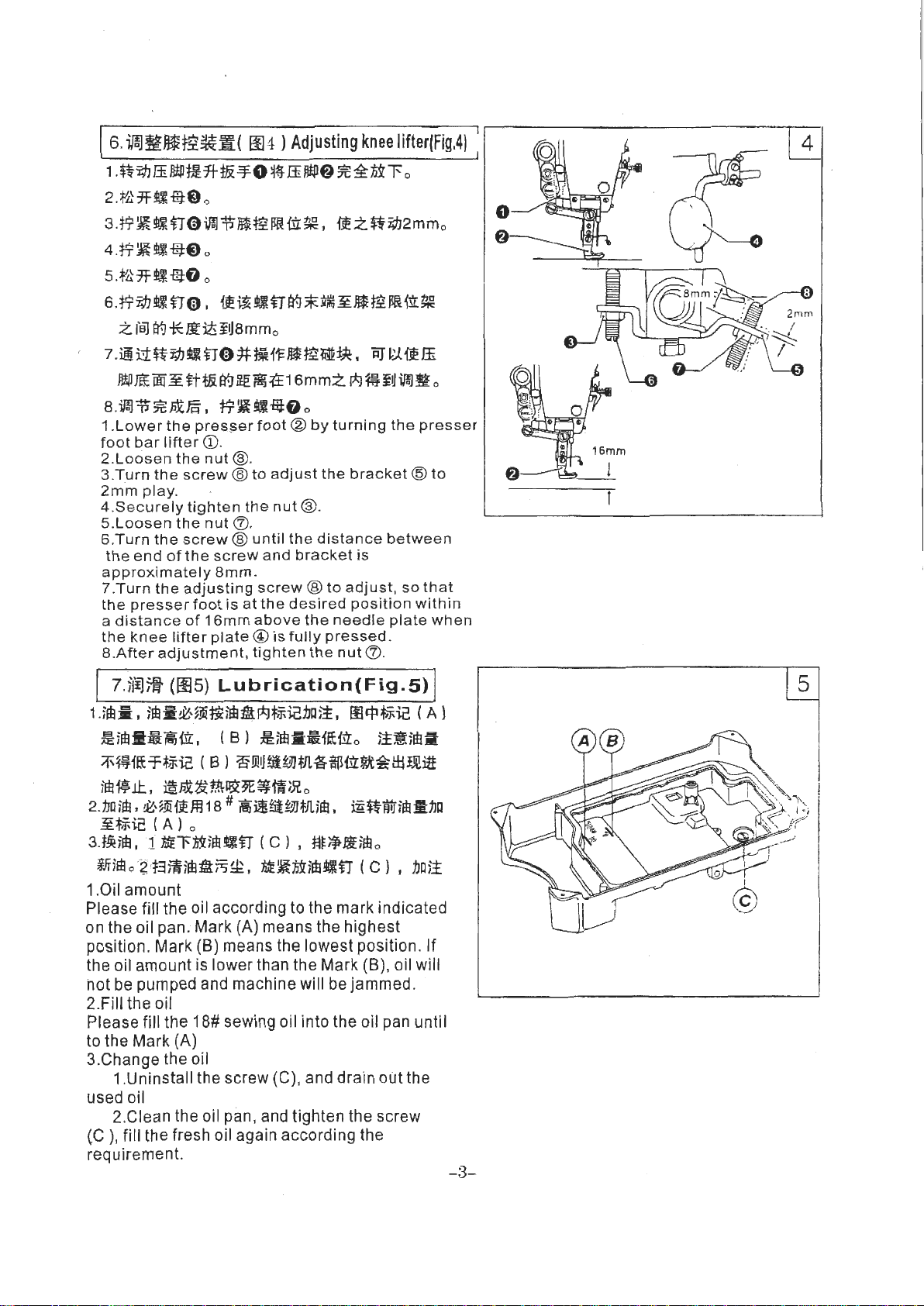

6. Adjusting the knee lifter ........................................................................... 3

7. Lubrication ................................................................................................ 3

8. Test operation ........................................................................................... 4

9. Installing the needle ................................................................................. 5

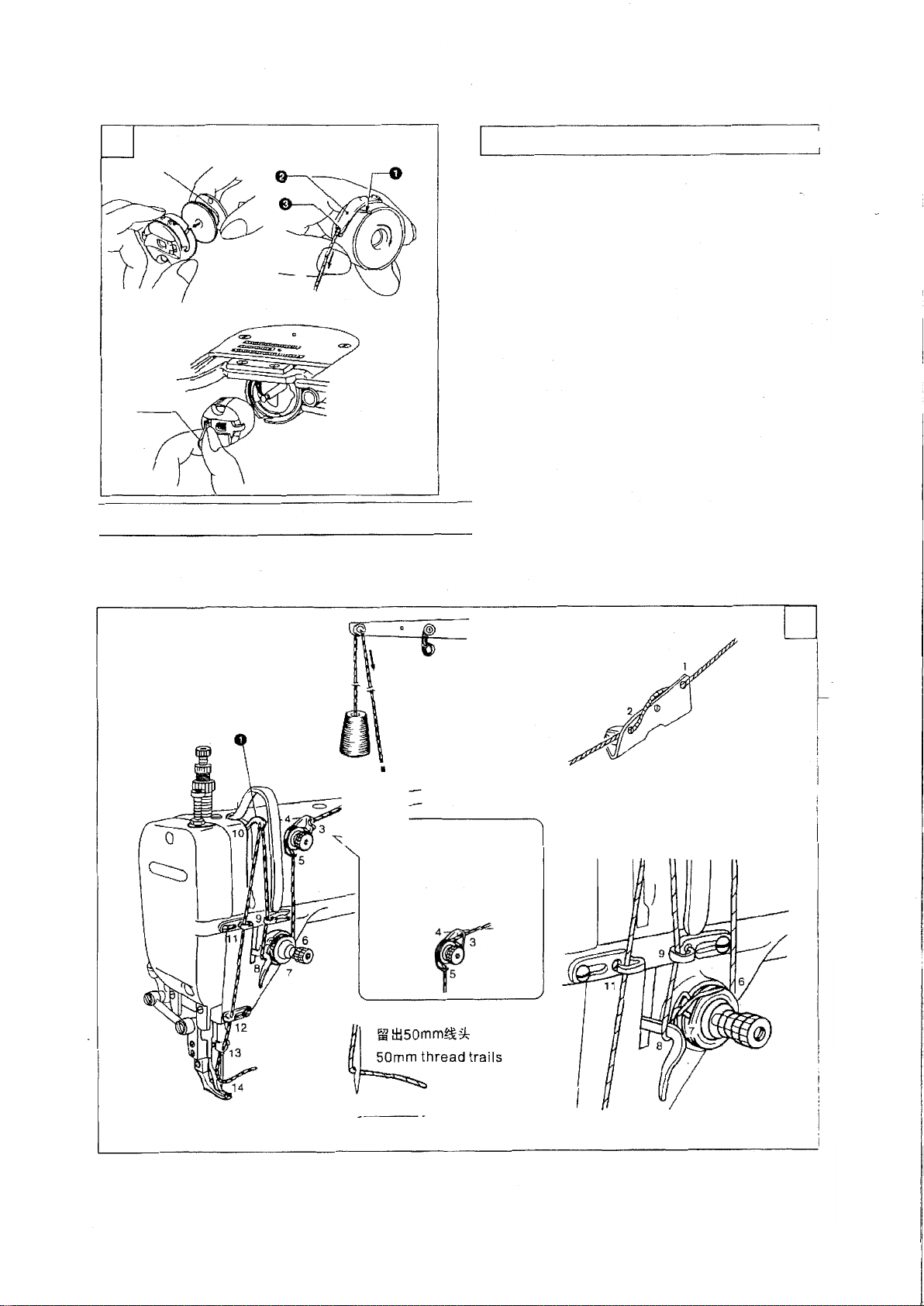

10. Removing the bobbin case .................................................................... 5

11. Windingthe bobbin thread .................................................................... 5

12. Threading the bobbin thread ................................................................. 6

13. Threading the needle thread ................................................................. 6

14. Adjusting the stitch length .................................................................... 7

15. Sewing and backtacking ........................................................................ 7

16. Adjusting the thread tension ................................................................. 8

17. Adjusting the presser foot pressure ..................................................... 8

18. Adjusting the trailing length after thread trimming ............................. 9

19. Adjusting the thread tension spring ..................................................... 9

20. Adjusting the upper thread guide ....................................................... 10

21.

Adjusting the presser foot height

........................................................

10

22. Adjusting the feed dog height ............................................................. 10

23. Adjusting the feed dog angle ...............................................................11

24. Adjusting the difference of stitch length between the forward and

back tacking ..........................................................................................11