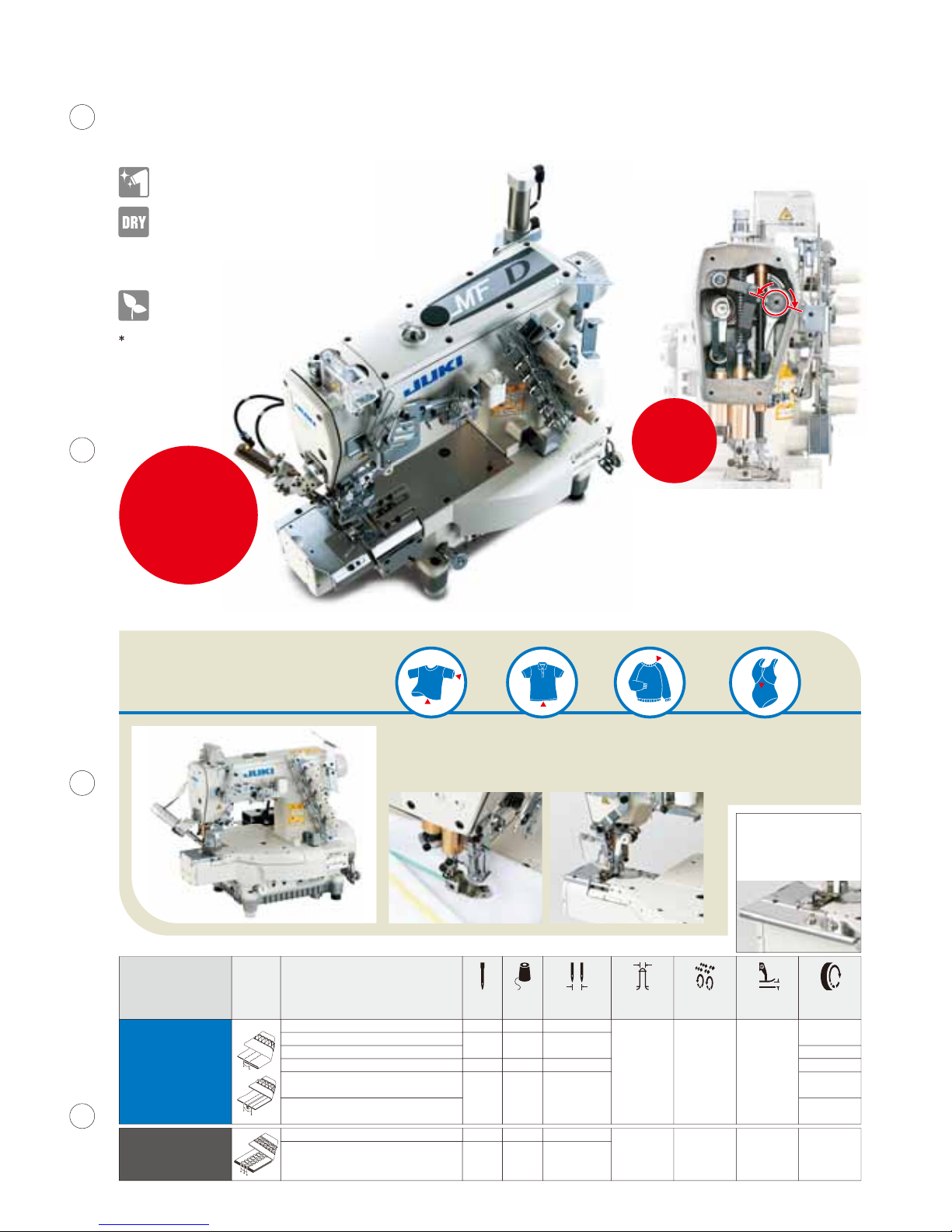

In the case of looper thread breakage,

the looper thread twining prevention

mechanism is activated to trim the

looper thread before the thread twines

on the looper thread cam. In this way,

the looper thread twining prevention

mechanism prevents the looper

thread from twining on the looper thread cam. In addition, the looper

thread cam, which has been incorporated in the sewing machine, has

been changed so that it is mounted outside of the sewing machine. The

externally-mounted looper thread cam promises improved maintainability.

As a result of the commonality of components, commercially-available

components (presser foot, throat plate and needle clamp) are now

applicable and easily obtainable.

Seam quality is improved!!

Simplified maintenance mechanism

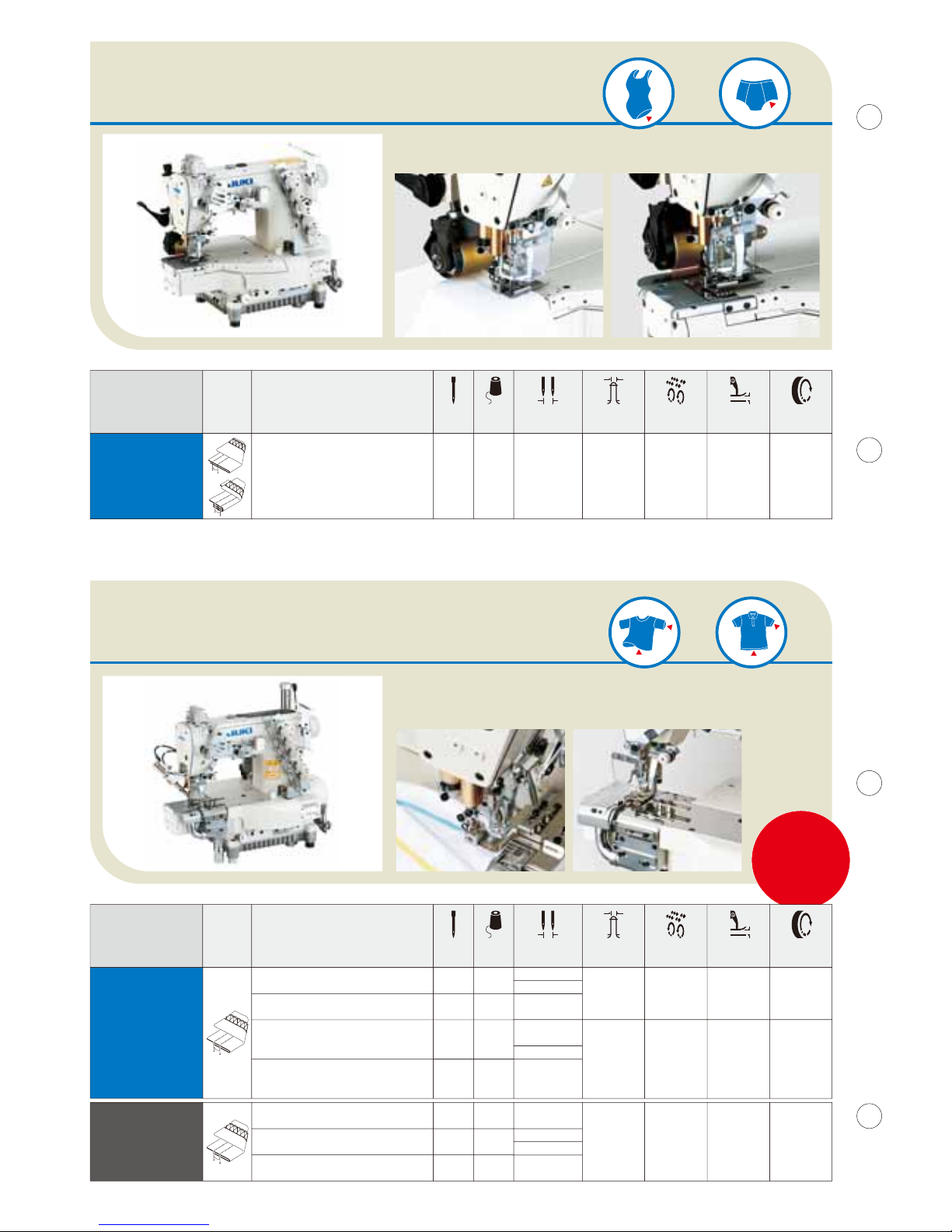

All of the sewing machines with

a thread trimmer are provided

with a direct-drive motor.

The direct-drive motor system has been

adopted by all of the sewing machines with

a thread trimmer. As a result, the sewing

machine starts up swiftly and promises

increased stop accuracy, thereby

demonstrating improved responsiveness.

In addition, the machine is no longer

provided with a V-belt. This means that the

adoption of the direct-drive motor is also

effective in the elimination of belt shavings. Power is directly transmitted

from the motor to the sewing machine, thereby contributing to reduced

power consumption. (This sewing machine reduces power consumption

by 27% as compared with the conventional models.)

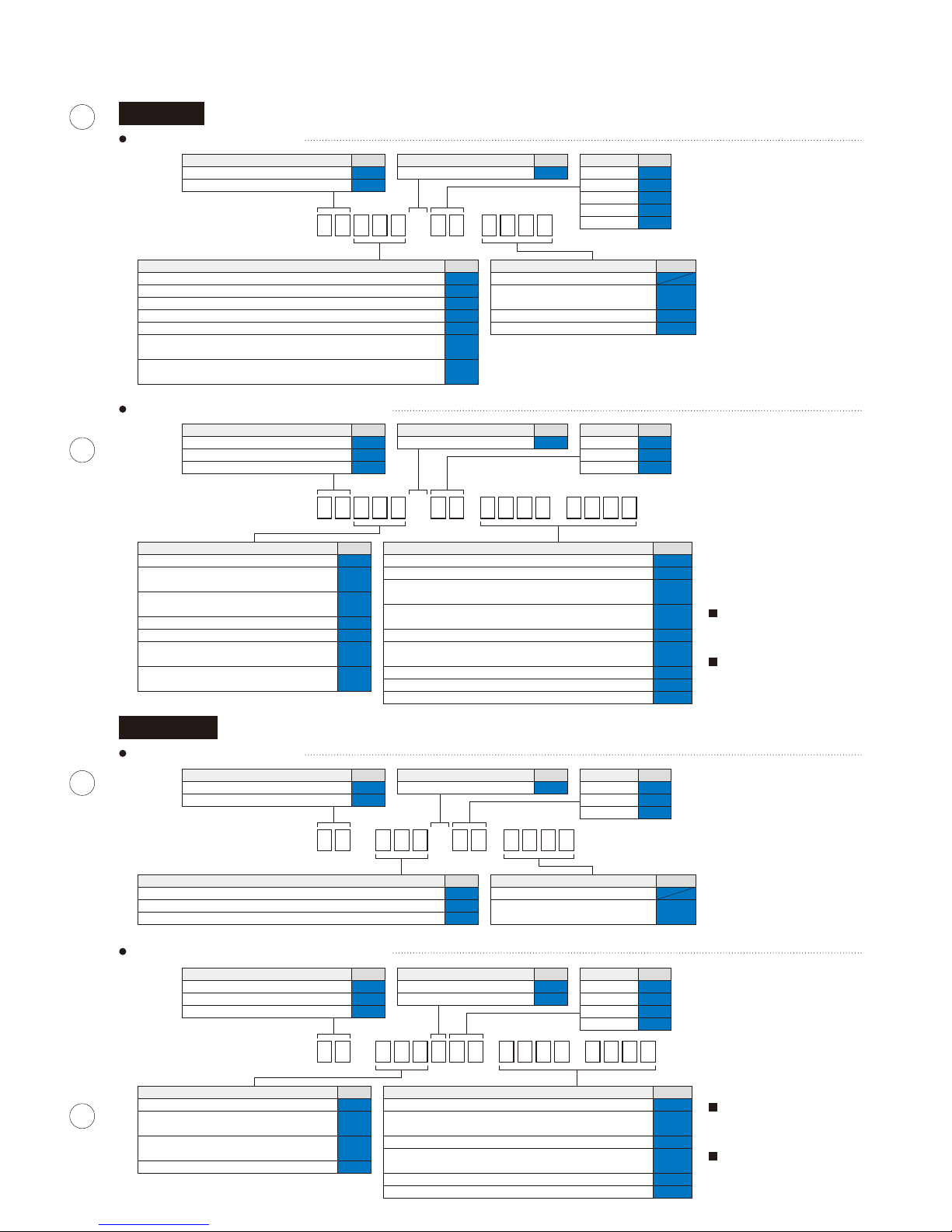

MF7823/UT22/SC510

MF-7923/UT57/SC921/CP18

Servomotor

Direct-drive motor

Commercially-available gauge components

are applicable with no additional work.

The looper thread twining prevention mechanism has been

improved and is provided as standard for the sewing machine.

The

world's

first

27%

Power

consumption

Reduced by

Main

feed dog

Differential

feed dog

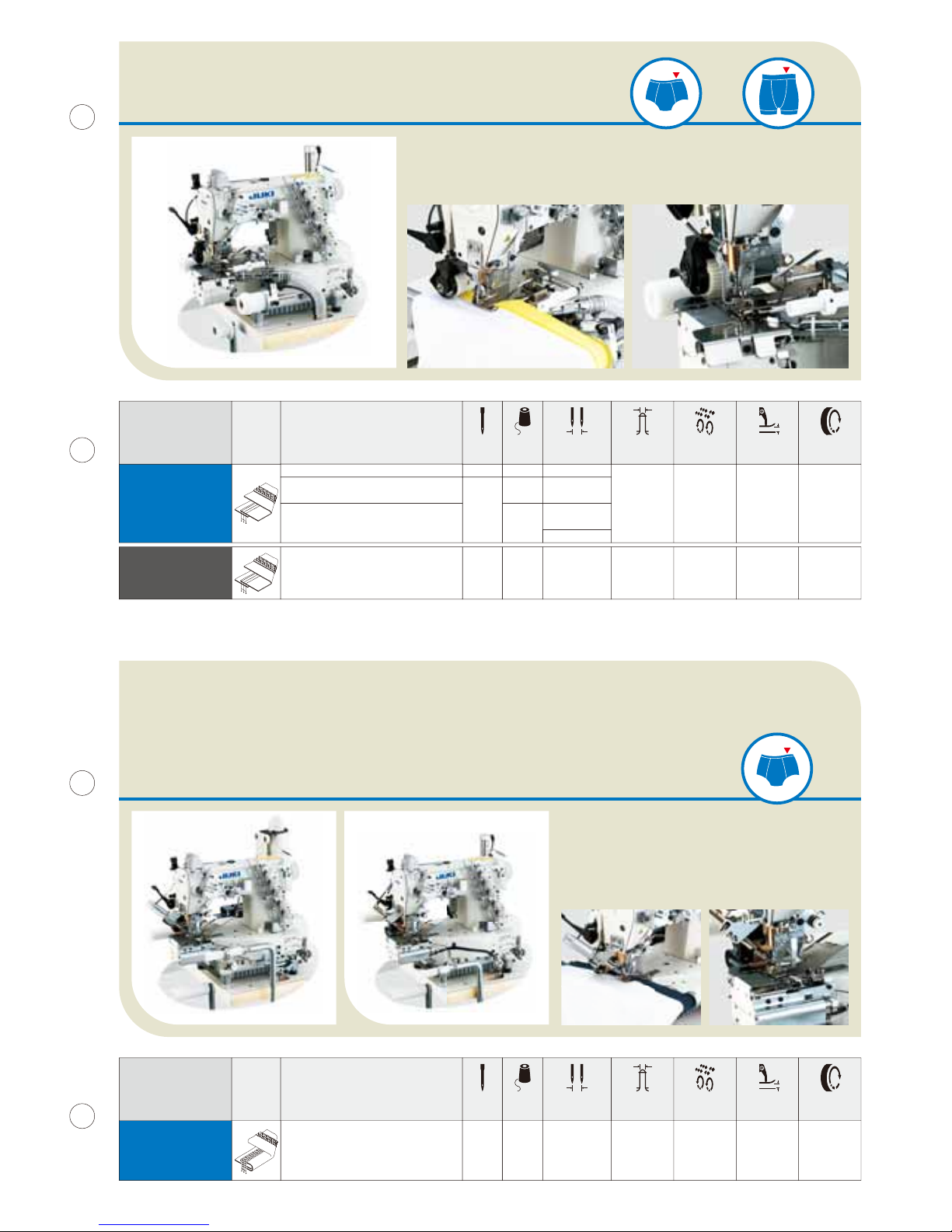

The feed locus can be adjusted externally. The

feed locus is now adjustable in terms of the

vertical direction and horizontal direction, thereby

improving responsiveness to sewing materials.

Thanks to the new feed mechanism,

many different types of sewing are achieved.

Elastic material or delicate material can be

sewn with the presser foot kept slightly raised.

This effectively helps reduce the degree of

slippage, warpage and damage of the material.

Micro-lifter mechanism

It is possible to finely adjust

the differential feed amount

to a best-suited value for the

material to be used.

The differential feed ratio is

constant even if the stitch

length is changed.

Differential-feed micro-adjustment

mechanism

It is provided with many different sewing-related mechanisms which contribute to

improved seam quality, such as the new feed mechanism, and differential-feed

micro-adjustment mechanism. In addition, the machine is provided as standard with

a looper thread twining prevention mechanism for improved maintenance.

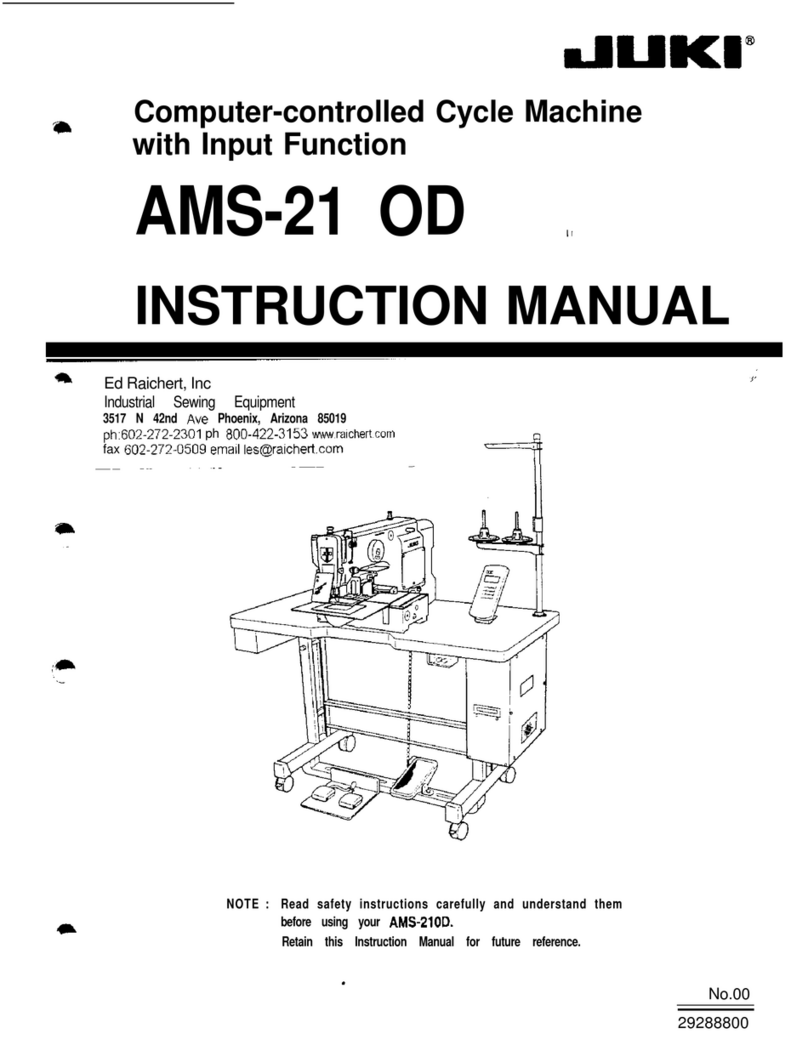

The MF-7900 Series is a newly developed

coverstitch machine provided with lots of

mechanisms for improving the seam quality.

MF-7900

Series

High-speed, Cylinder-bed,

Top & Bottom Coverstitch Machine

MF-7900/UT

Series

Direct-drive, High-speed, Cylinder-bed,

Top & Bottom Coverstitch Machine with Needle- and Looper- Thread Trimmer

MF-7900D

Series

Semi-dry-head, Cylinder-bed,

Top & Bottom Coverstitch Machine

MF-7900D/UT

Series

Semi-dry-head, Direct-drive, Cylinder-bed,

Top & Bottom Coverstitch Machine with Needle- and Looper- Thread Trimmer

Horizontal

direction

Vertical

direction

Expand

Contract

The

world's

first