Oil tank

Capacity: 220cc

Application

Dry type

Max. sewing speed

Distance from needle to machine arm

Needle gauge

Feed system

Max. stitch length

Thread take-up

Separately driven needle bar changeover mechanism

Opener system

Tensioner

Thread trimming method

Thread winder

Lift of the presser foot

Lubrication

Tank capacity

Lubricating oil

Needle

Power consumption

Outside dimensions of package

Machine head weight (including the package)

LH-4100 Series

F: Foundation S: Medium-weight G: Jeans and heavy-weight materials

Semi-dry-head

LH-4128(-7): 4,000sti/min LH-4168-7, 4188-7: 3,200sti/min

127mm(H)×267mm(W)

Changeover between the needle feed and bottom feed

5mm

Link type

Needle bar shaft link changeover method

Soft opener

Integral type (lockstitch type)

Direct-acting type

Driven by the arm shaft

By hand: 5.5mm, By knee: 13mm

Centralized tank system

220cc

JUKI New Defrix Oil NO.1

DP×5 #9〜#22 (S and F type) #16〜22 (G type)

650VA

739mm (H) × 378mm (W) × 768mm (L)

LH-4128 (-7): 68kg, LH-4168-7, 4188-7: 73kg ※+3 kg for the machine provided with an AK25.

LH-4128

LH-4128-7

LH-4168-7

LH-4188-7

1 / 8"〜1-1 / 2" (3.2〜38.1mm)

5 / 32"〜1-1 / 4" (4.0〜31.8mm)

5 / 32"〜1" (4.0〜25.4mm)

Model name

JUKI's dry technology has achieved the adoption of a dry

frame in all classes of machines, including those with

separately-driven needle bars (organized split needle

bar)/large hook. The dry frame eliminates oil dispersion from

the thread take-up and needle bar frame section, thereby

achieving a clean sewing environment. In order to use clean

oil in the hook section at all times, a centralized tank system

has been adopted for oiling. In addition, the hook section is

oiled using independent left and right pumps and oil paths,

whereby consistent oiling of the hook section is enabled

without being affected by the single-direction oil flow.

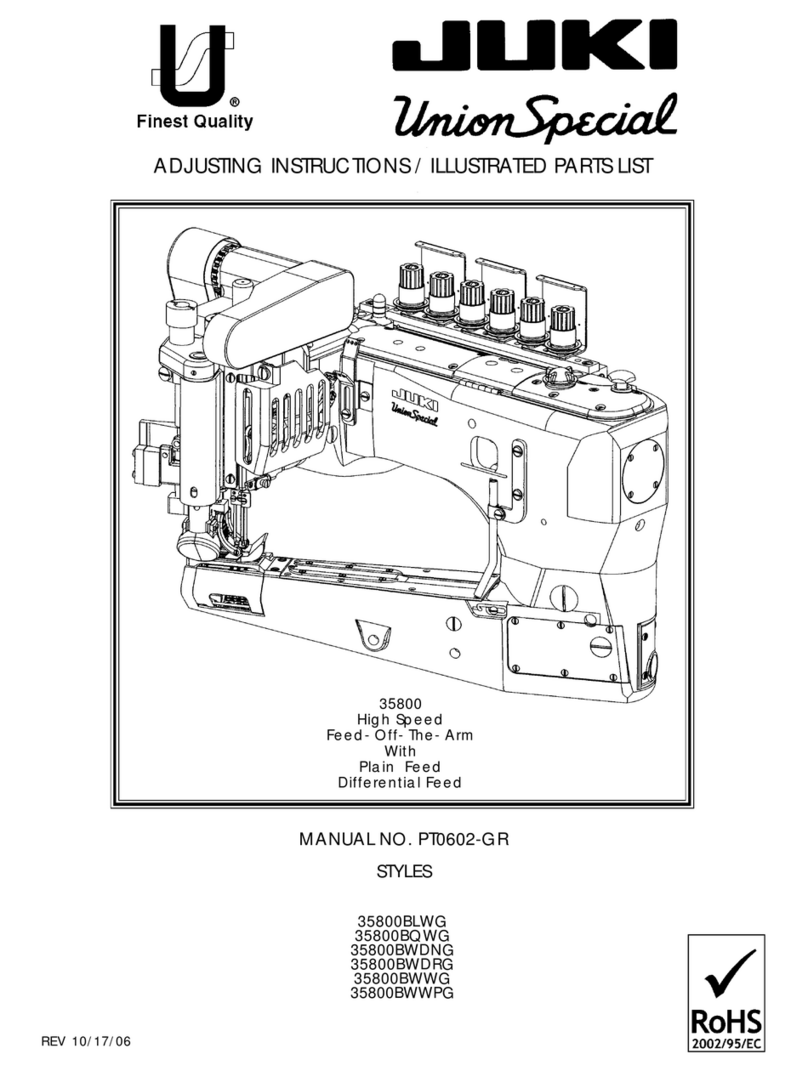

Replacement and adjustment of the gauge is necessary in

order to change the needle gauge according to the targeted

sewing operation. For the LH-4100 Series, the aforementioned

work is dramatically improved in efficiency.

The hook driving shaft saddle can be moved only by

loosening the screw in the base. In this case, neither the hook

driving shaft gear nor lower shaft is required to be loosened.

In addition, the hook does not turn when moving the hook

driving shaft saddle. This means that "hook timing

adjustment", which is the most troublesome work

associated with the procedure, is not required. As a result,

the time required to complete the gauge replacement for

this machine is reduced to a half or less as compared with

the conventional machines.

Dry frame is achieved for all classes of machines

Trouble and time required to change the gauge is reduced

to half or less (applies to all classes of machines)

SPECIFICATIONS

Hook timing adjustment is not required