JUKI HZL-12Z User manual

Other JUKI Sewing Machine manuals

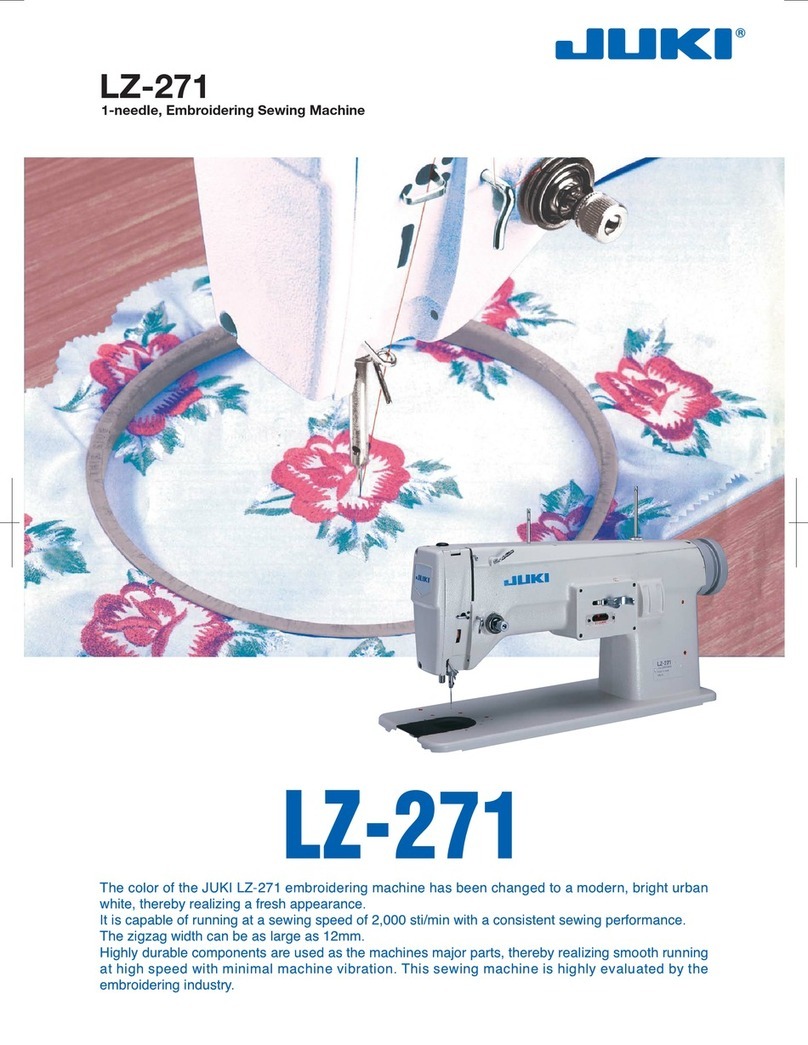

JUKI

JUKI LK-1900S-SS User manual

JUKI

JUKI LBH-1796A User manual

JUKI

JUKI MO-613V User manual

JUKI

JUKI LU-562 User manual

JUKI

JUKI MH-481 User manual

JUKI

JUKI LK-1850 Series User manual

JUKI

JUKI DDL-9000B-SS User manual

JUKI

JUKI ASN-690 User manual

JUKI

JUKI MO-6900G Series User manual

JUKI

JUKI DDL-8700B-7 User manual

JUKI

JUKI MCS-1500N User manual

JUKI

JUKI DDL-9000B User manual

JUKI

JUKI LBH-772NV-1 User manual

JUKI

JUKI HZL-F series User manual

JUKI

JUKI LBH-1795AN User manual

JUKI

JUKI MP-200NS User manual

JUKI

JUKI MS-1190/V045 User manual

JUKI

JUKI DDL-9000C-F Series User manual

JUKI

JUKI MO-644DN User manual

JUKI

JUKI S057 User manual