8.

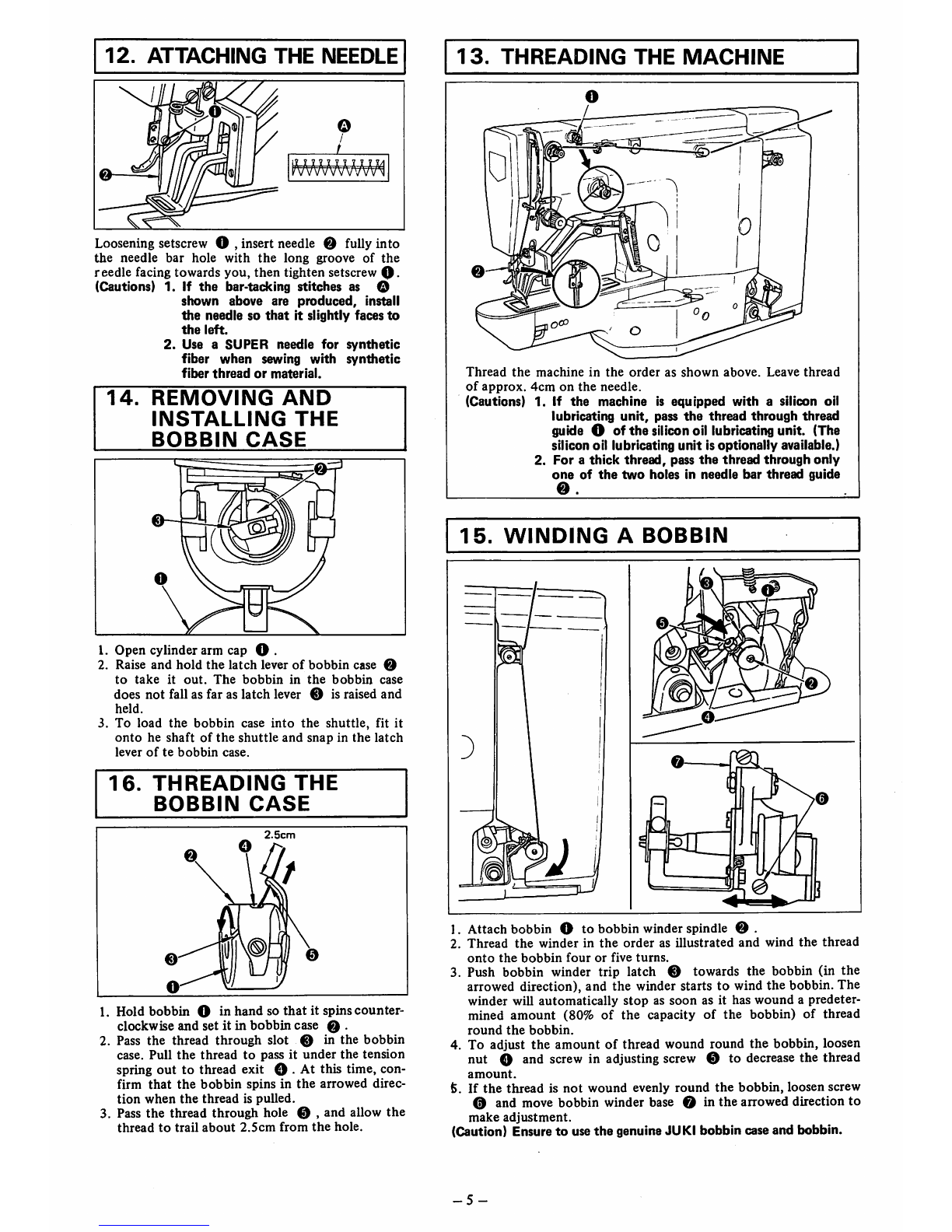

ATTACHING

THE

CHAIN

Hook S-shaped hook 0into the hole in the tip of

starting lever O , and

attach

chain O to

the

S-

shaped

hook.

9.

LUBRICATION

Supply

Supply

1. Lubricate the machine once a day from lubrication hole O . The

machine can also be lubricated by removingrubber plug O .

2. Use Juki New Defrix Oil No. 2 or spindle oil No. 2 as the lubricating

oil.

* When using

the

thread

guide (optionally available)

Supply silicone oil through silicone oil lubricating hole 0 when using

thread guide

0,

At this time, check

that

the

thread which has passed through thread

guide 0 has

the

silicone oil

on

it.

10.

OPERATING

THE

SEWING

MACHINE

Operate

the

sewing

machine

in

the

following

procedure:

1.

Turn

on

the

power

switch.

2. Depress the starting pedal a little, and the work clamp foot will come down. When you want to make the work clamp foot

go

up,

release

the

pedal.

3. Further depress the pedal, and

the

sewing machine starts bar-tacking. Immediately after the sewing machine starts bar-tacking,

release

the

pedal.

4. When the machine has completed the specified bar-tacking cycle, the work clamp foot will automatically

go*

up, and the

needle

and

bobbin

threads

are

trimmed

before

the

machine

stops.

(Cautions) 1. Be sure to

release

the pedal as soon as the machinestarts bar-tacking, or

else

the

machine will

not

stop

at

the

predetermined point.

2. If you fail to depress the pedal sufficiently, the machine may stop at the

first stitch. In this case, depress

the

pedal gain sufficiently.

3. If

the

machine will not start evenwhen you depress it strong enough, turn

of the power switch, and remove the belt cover. Then turn changeover

pulley

0

(Knurled

part)

in

the

arrowed

direction

of

low-spe^

pulley

0

4. This

sewing

machine may run rather unsmoothly on a cold morning

because it uses grease for the lubrication of several parts. In such a case,

allow

the

machineto idlefor 5 or 6 times before starting

the

work.

^ To

operate

the

sewing maclne manually;

Turn off the power switch, remove the upper end of spring 0 , give low-speed pulley

0 two turns in the arrowed direction and the work clamp foot willcomedown. Then

depress

the

starting pedal, and

the

machine can be run manually.

11.

MATERIALS

AND

NEEDLES

TO

BE

USED

Material

Needle

Needle plate needle hole guide

Class

or

work

Extra

light-weight

material

#11

(DPx5)

D2426282C00

Knit

goods,

tricot

wear

Synthetic

fiber

material

#14

(DPx5, SUPER needle)

B2426280000

(standard)

Men's

suits.

Ladies'

wear

Medium-weight

material

#16(DPx5)

B2426280000

(standard)

Men's

suits.

Ladies'

wear

Heavy-weight

material

#18(DPx5)

B242628O0OO(standard)

Working

wear,

overcoats

-4-