i

CONTENTS

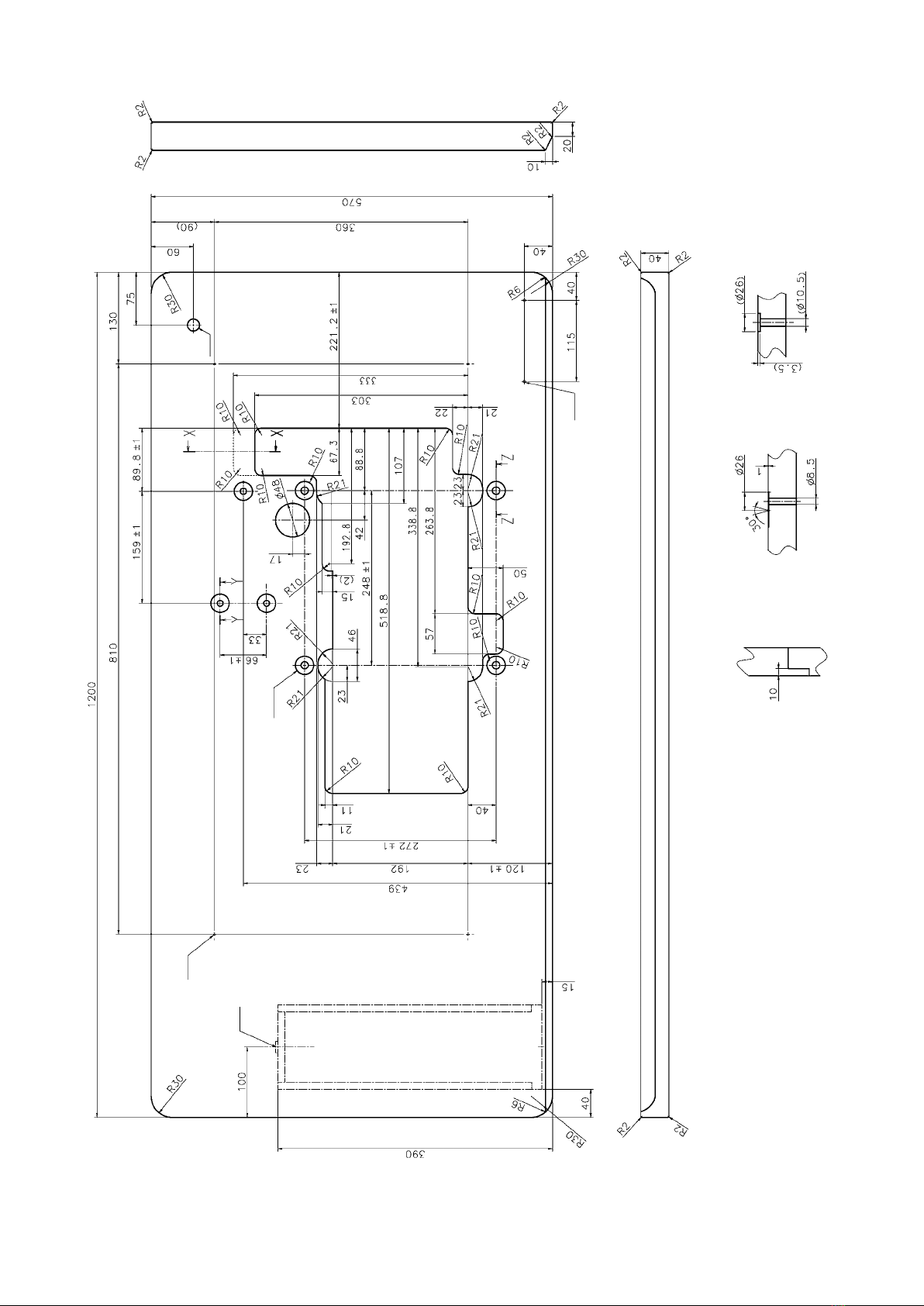

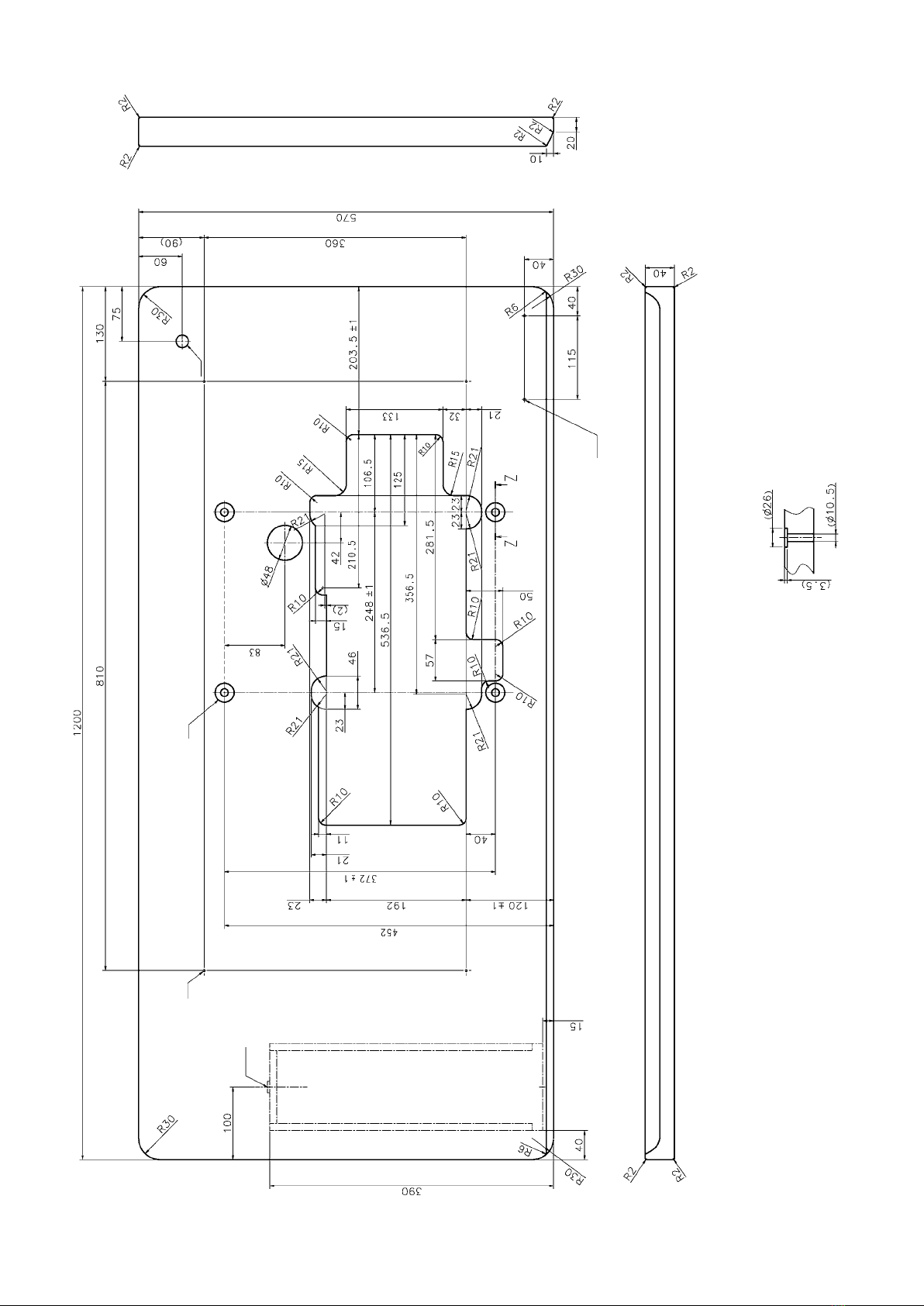

Ⅰ. SPECIFICATIONS .........................................................................................................1

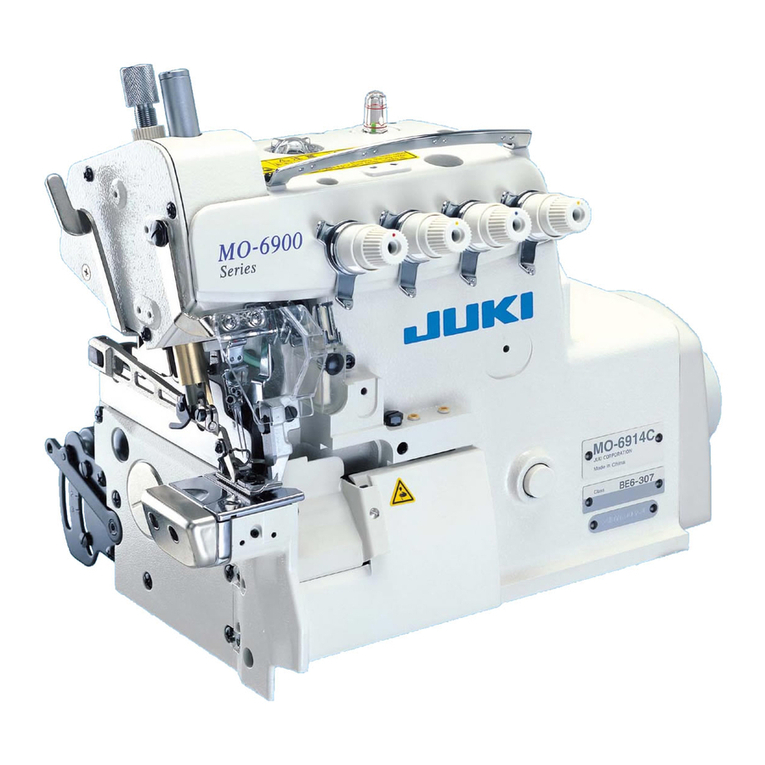

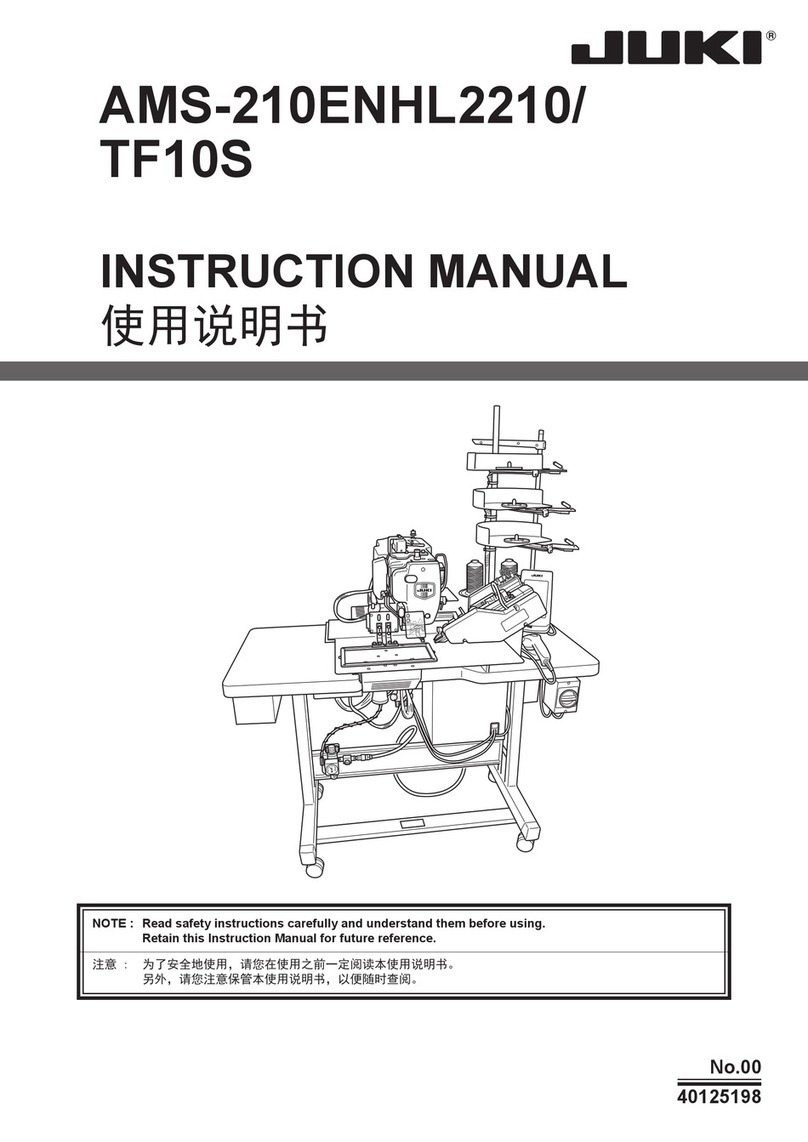

Ⅱ. CONFIGURATION OF THE MACHINE COMPONENTS ..............................................2

Ⅲ.

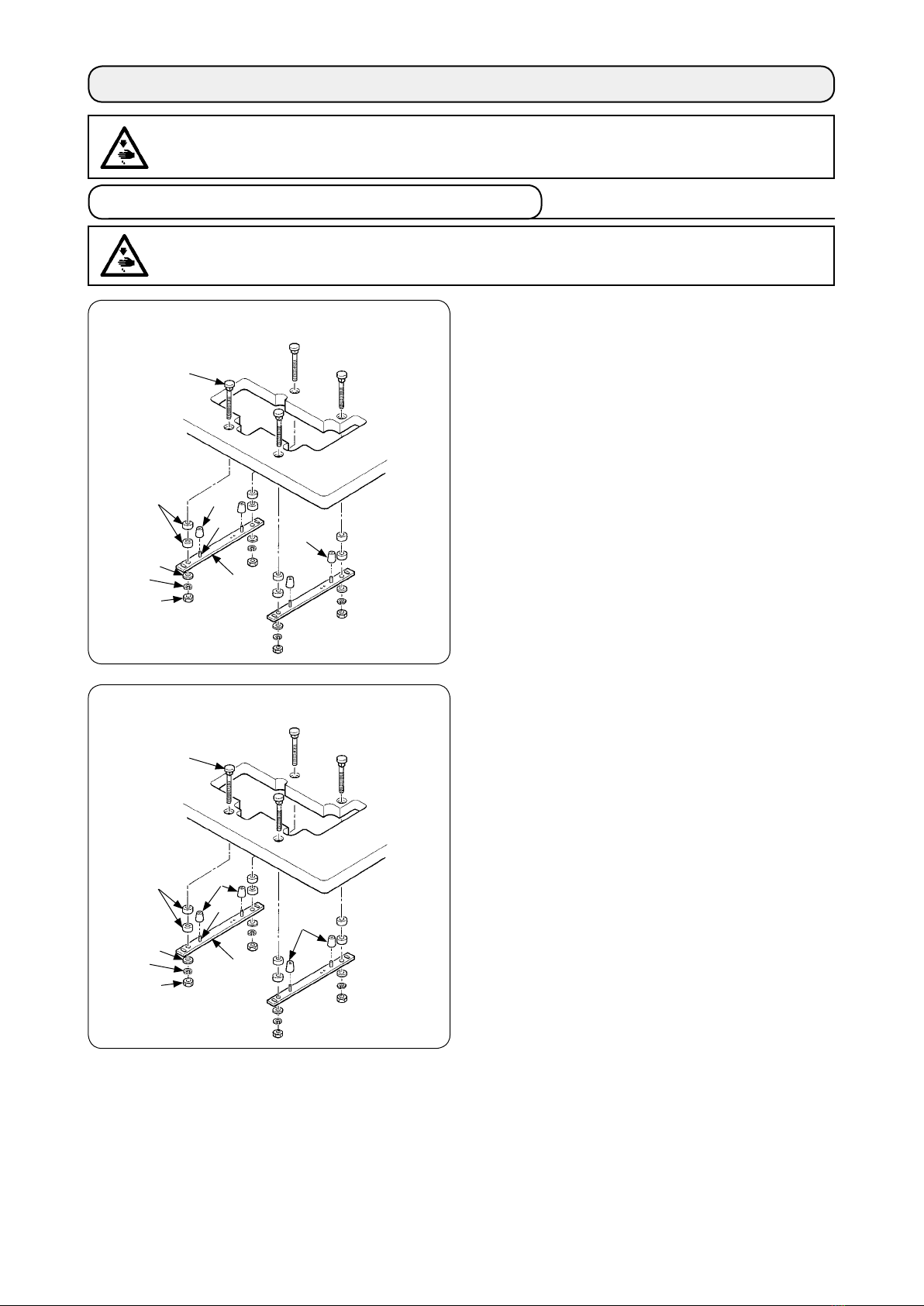

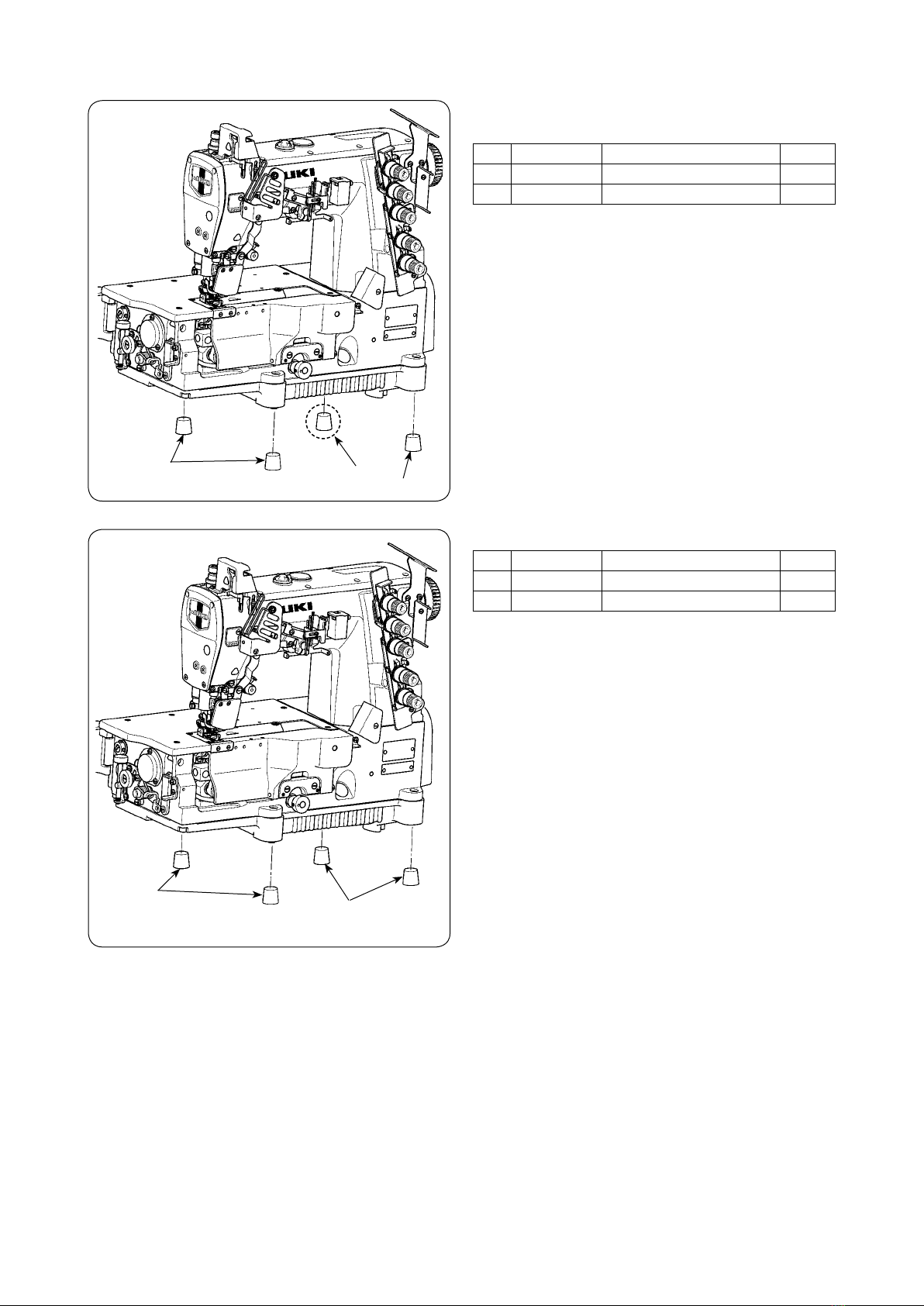

INSTALLATION......................................................................................................................3

1. Installing the machine head onto the table................................................................................ 3

2.Selecting the motor pulley and the belt....................................................................................... 7

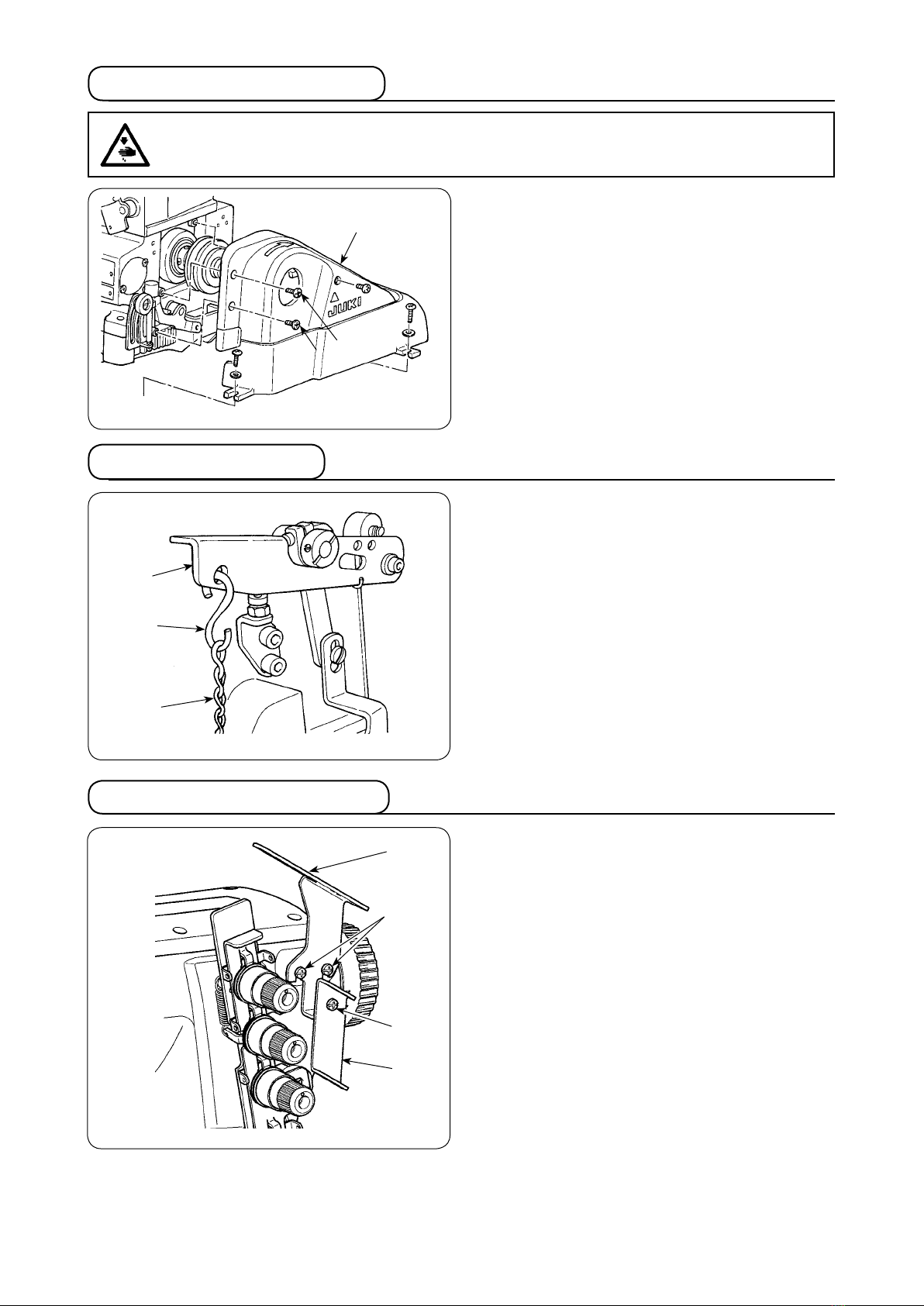

3.Installing the motor ....................................................................................................................... 7

4.Setting the belt............................................................................................................................... 7

5.Installing the belt cover................................................................................................................. 8

6.Installing the chain ........................................................................................................................ 8

7.Installing the thread guide............................................................................................................ 8

8.Installing the needle bar thread take-up cover ........................................................................... 9

Ⅳ. LUBRICATION AND OILING ........................................................................................9

1.Lubricating oil................................................................................................................................ 9

2.Oiling............................................................................................................................................. 10

3.Silicon oil lubricating unit........................................................................................................... 10

Ⅴ. OPERATION................................................................................................................11

1.Needle........................................................................................................................................... 11

2.Attaching the needle ................................................................................................................... 11

3.Threading the machine head...................................................................................................... 12

4.Adjusting the stitch length ......................................................................................................... 13

5.Adjusting the differential feed ratio ........................................................................................... 13

6.

Adjusting the presser foot pressure ..................................................................................................14

7.Adjusting the thread tension...................................................................................................... 14

Ⅵ.

ADJUSTING THE SEWING MACHINE......................................................................................15

1.Adjusting the silicon container thread guide............................................................................ 15

2.Adjusting the needle bar thread take-up thread receiver ........................................................ 15

3.Adjusting the rocking thread take-up........................................................................................ 16

4.Adjusting the spreader thread guide......................................................................................... 16

5.Adjusting the looper thread cam................................................................................................ 16

6.Adjusting the looper thread cam eyelet .................................................................................... 17

7.Adjusting the looper.................................................................................................................... 17

8.Adjusting the height of the needle............................................................................................. 18

9.Adjusting the rear needle guard................................................................................................. 18

10.Relation between the rocking thread take-up timing and the needle thread loop ................ 19

(1) Adjustment by means of the crank ............................................................................................. 19

(2) Adjustment by the eccentric cam................................................................................................ 19

11.Adjusting the height of the feed dog ......................................................................................... 20

12.Installing position of the spreader............................................................................................. 20

13.Adjusting the spreader thread guide and the needle clamp thread guide............................. 21

14.Adjusting the front needle guard............................................................................................... 21

15.

Adjusting the presser foot lift ......................................................................................................22

16.Adjusting the micro-lifter............................................................................................................ 22

17.Adjusting the feed locus............................................................................................................. 23

(1) Changing the feed driving movement......................................................................................... 23

(2) Changing the feed rock movement ............................................................................................ 24

(3) Restoring to the standard adjustment ........................................................................................ 24

18.Adjustment value of balloon ...................................................................................................... 25

19. Adjustment of the feed dog in longitudinal direction ............................................................. 27

(1) Longitudinal position of the feed dog.......................................................................................... 27

(2) For C11....................................................................................................................................... 28

Ⅶ.

MAINTENANCE ...................................................................................................................29

1. Cleaning the sewing machine ................................................................................................... 29

2. Replacing the lubricating oil...................................................................................................... 29

3. Inspecing and replacing the oil lter ........................................................................................ 29