iii

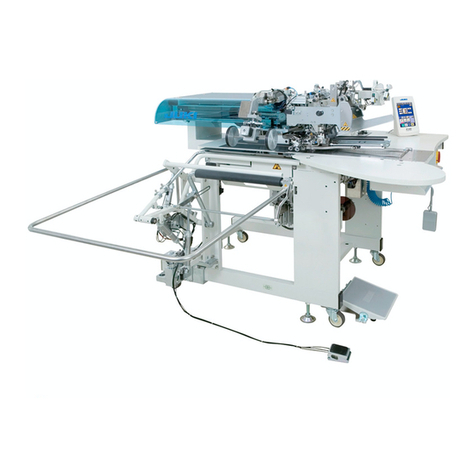

Transportation

1. Be sure to lift and move the machine in a safe manner taking the machine weight in consideration. Refer

to the text of the engineer's manual for the mass of the machine.

2. Be sure to take sufcient safety measures to prevent falling or dropping before lifting or moving the

machine in order to protect against accident that can result in personal injury or death.

3. Once the machine has been unpacked, never re-pack it for transportation to protect the machine against

breakage resulting from unexpected accident or dropping.

Unpacking

1. Be sure to unpack the machine in the prescribed order in order to prevent accident that can result in

personal injury or death. In the case the machine is crated, in particular, be sure to carefully check nails.

The nails have to be removed.

2. Be sure to check the machine for the position of its center of gravity and take it out from the package

carefully in order to prevent accident that can result in personal injury or death.

Installation

(I) Table and table stand

1.

Be sure to use JUKI genuine table and table stand in order to prevent accident that can result in personal

injury or death. If it is inevitable to use a table and table stand which are not JUKI genuine ones, select the

table and table stand which are able to support the machine weight and reaction force during operation.

2. If casters are tted to the table stand, be sure to use the casters with a locking mechanism and lock

them to secure the machine during the operation, maintenance, inspection and repair in order to prevent

accident that can result in personal injury or death.

(II) Cable and wiring

1.

Be sure to prevent an extra force from being applied to the cable during the use in order to prevent electri-

cal-shock, earth-leakage or re accident. In addition, if it is necessary to cable near the operating section

such as the V-belt, be sure to provide a space of 30 mm or more between the operating section and the cable.

2. Be sure to avoid starburst connection in order to prevent electrical-shock, earth-leakage or re accident.

3. Be sure to securely connect the connectors in order to prevent electrical-shock, earth-leakage or re

accident. In addition, be sure to remove the connector while holding its connector section.

(III) Grounding

1. Be sure to have an electrical expert install an appropriate power plug in order to prevent accident caused

by earth-leakage or dielectric strength voltage fault. In addition, be sure to connect the power plug to the

grounded outlet without exceptions.

2. Be sure to ground the earth cable in order to prevent accident caused by earth leakage.

(IV) Motor

1. Be sure to use the specied rated motor (JUKI genuine product) in order to prevent accident caused by

burnout.

2. If a commercially available clutch motor is used with the machine, be sure to select one with an entan-

glement preventive pulley cover in order to protect against being entangled by the V-belt.

Before operation

1. Be sure to make sure that the connectors and cables are free from damage, dropout and looseness be-

fore turning the power on in order to prevent accident resulting in personal injury or death.

2. Never put your hand into the moving sections of the machine in order to prevent accident that can result

in personal injury or death.

In addition, check to be sure that the direction of rotation of the pulley agrees with the arrow shown on

pulley.

3. If the table stand with casters is used, be sure to secure the table stand by locking the casters or with

adjusters, if provided, in order to protect against accident caused by abrupt start of the machine.

During operation

1. Be sure not to put your ngers, hair or clothing close to the moving sections such as the handwheel,

hand pulley and motor or place something near those sections while the machine is in operation in order

to prevent accident caused by entanglement that can result in personal injury or death.

2. Be sure not to place your ngers near the surround area of the needle or inside the thread take-up lever

cover when turning the power on or while the machine is in operation in order to prevent accident that

can result in personal injury or death.

3. The machine runs at a high speed. Never bring your hands near the moving sections such as looper,

spreader, needle bar, hook and cloth trimming knife during operation in order to protect your hands

against injury. In addition, be sure to turn the power off and check to be sure that the machine complete-

ly stops before changing the thread.

4. Be careful not to allow your ngers or any other parts of your body to be caught between the machine

and table when removing the machine from or replacing it on the table in order to prevent accident that

can result in personal injury or death.

5.

Be sure to turn the power off and check to be sure that the machine and motor completely stop before re-

moving the belt cover and V-belt in order to prevent accident caused by abrupt start of the machine or motor.

6.

If a servomotor is used with the machine, the motor does not produce noise while the machine is at rest.

Be sure not to forget to turn the power off in order to prevent accident caused by abrupt start of the motor.

7. Never use the machine with the cooling opening of the motor power box shielded in order to prevent re

accident by overheat.