(3) Optional sections.................................................................................................................. 59

1) SA-117 (dart stretcher unit) ...........................................................................................................59

2) SA-118 (shim unit) ..........................................................................................................................61

3) SA-119 (suction unit)......................................................................................................................65

4) SA-120 (automatic interlining feeder unit) ...................................................................................71

5) SA-121 (pattern matching marking light unit)..............................................................................75

6) SA-127 (suction motor unit)...........................................................................................................77

7) SP-46 (clamp bar stacker unit) ......................................................................................................81

8) SP-47 (roller stacker unit) ..............................................................................................................95

4. Operation panel and related parts....................................................................... 97

(1) Configuration of IP-310 ........................................................................................................ 97

(2) Memory switch...................................................................................................................... 98

(3) Memory switch data list ....................................................................................................... 99

(4) Optional setting list ............................................................................................................ 106

5. Supplemental remarks of each function number and

explanation of each function ............................................................................. 107

(1) Version display ................................................................................................................... 107

(2) Keylock setup ..................................................................................................................... 108

(3) Communication screens of the maintenance personnel level ....................................... 109

(4) Information screen at the maintenance personnel level................................................. 113

(5) Check program ................................................................................................................... 115

(6) Pedal volume adjustments ................................................................................................ 134

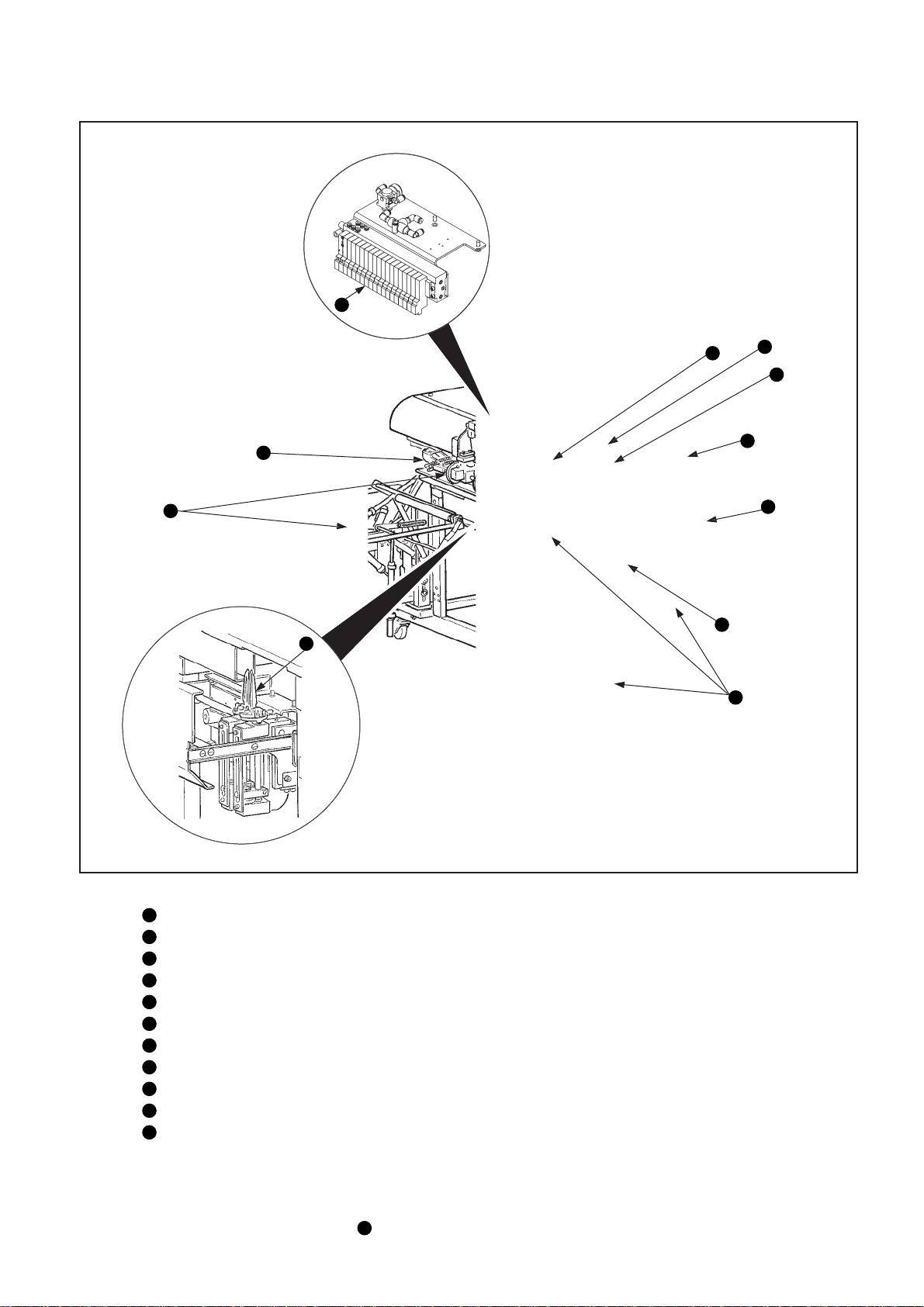

6. Control box......................................................................................................... 137

(1) Description of each constitutive part ............................................................................... 137

1) Function of boards in the control box and installation position............................................. 137

2) Function of boards in the operation panel (IP-310) and installation position ........................137

3) Function of INT board (relay board) and installation position .................................................138

4) Function of PMDC board (optional component) and installation position ............................ 138

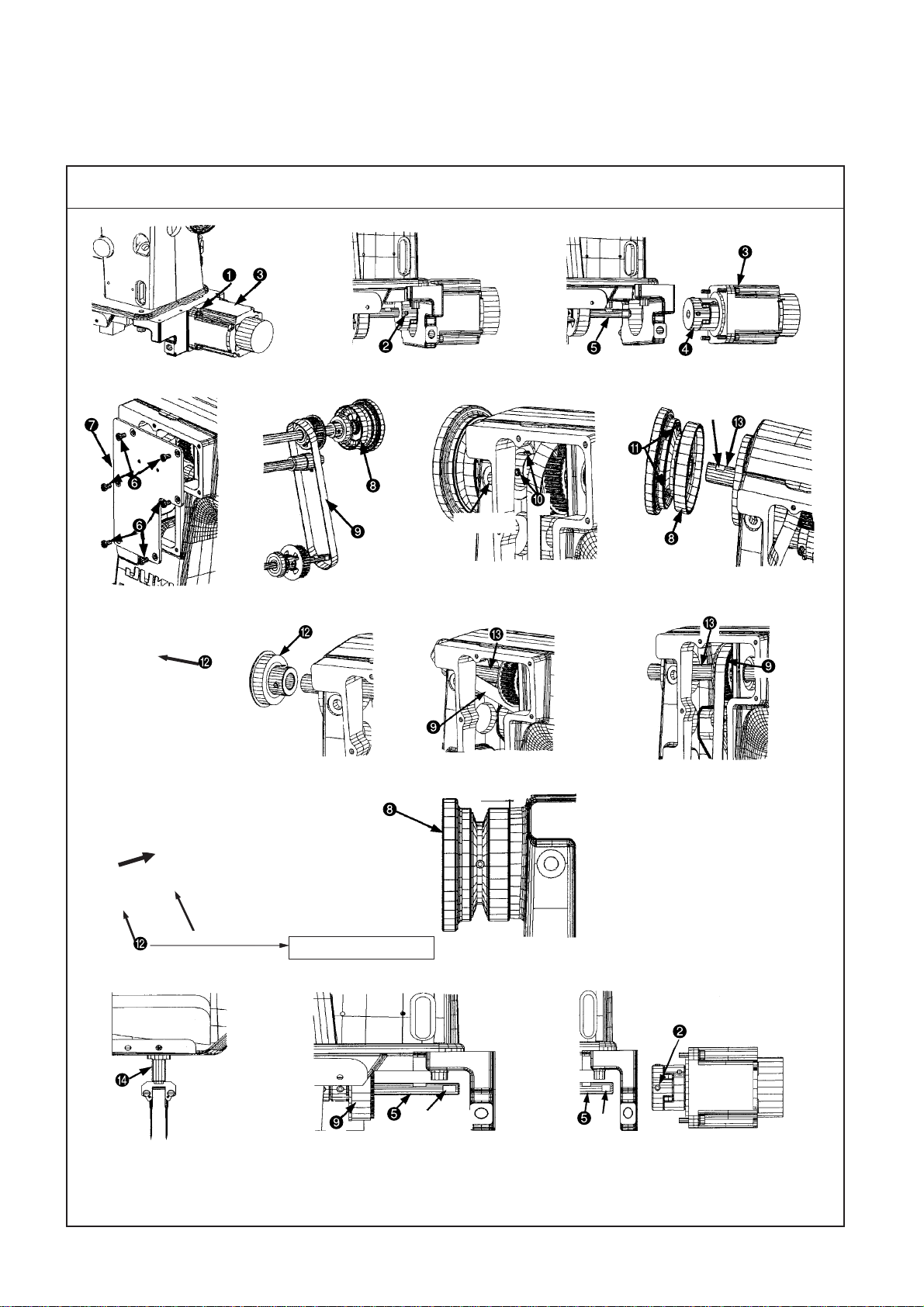

(2) Replacement of part ........................................................................................................... 139

1) Replacement of fuses.................................................................................................................. 139

2) Replace the board.........................................................................................................................139

(3) Description of dip switches ............................................................................................... 143

1) MAIN board dip switch ................................................................................................................ 143

2) SDC board dip switch.................................................................................................................. 143

3) PANEL board dip switch ............................................................................................................. 143

4) PMDC board dip switch (For roller stacker)...............................................................................143

(4) Modification of the source voltage specifications .......................................................... 144

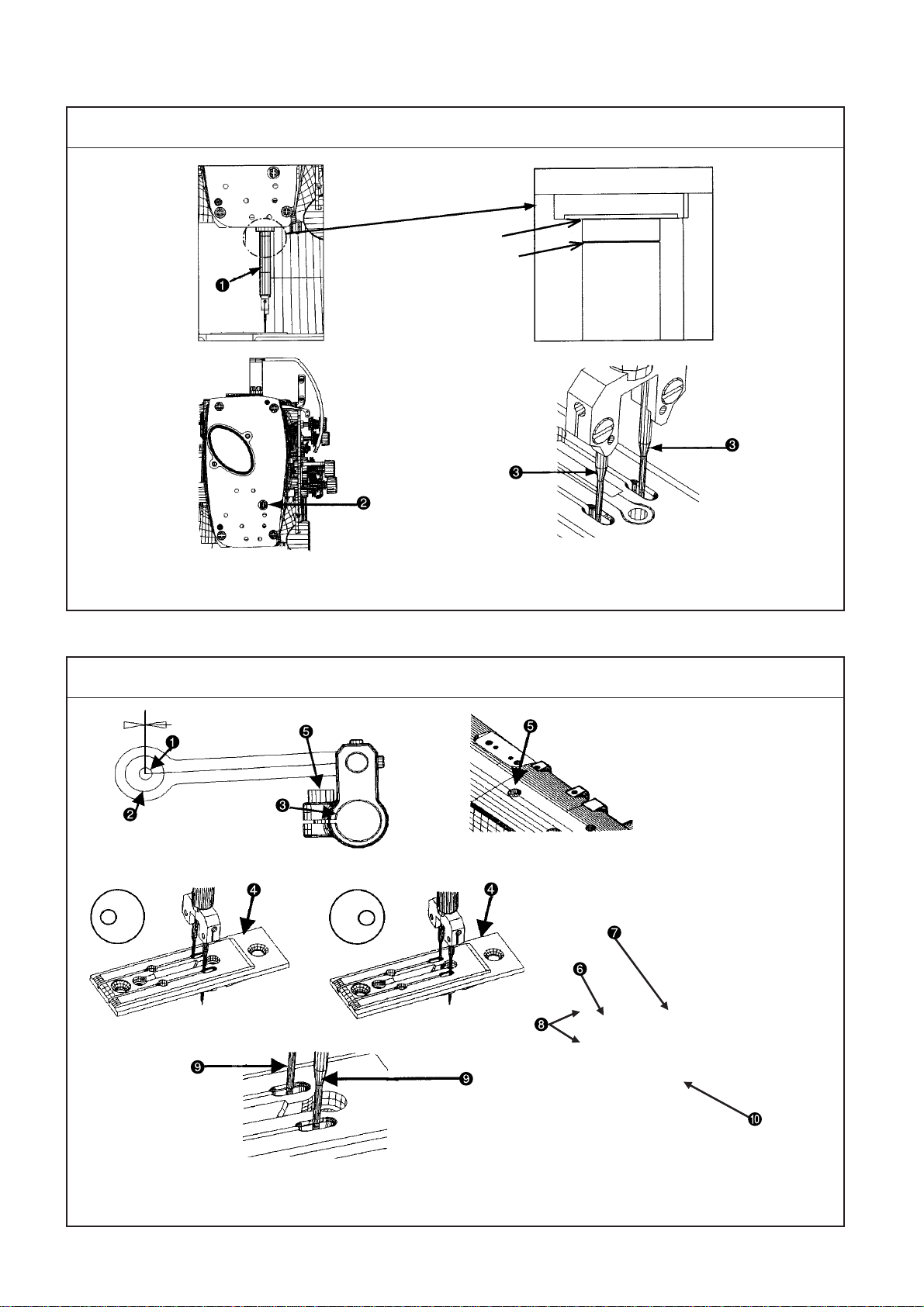

7. Names of switches and switch sensors and installation places .................. 145

8. Maintenance....................................................................................................... 151

(1) Machine head maintenance-related matters .................................................................... 151

(2) Application of grease and Locktight................................................................................. 152

(3) Spots where grease • adhesive agents are used ............................................................ 153

(4) Replenishing grease to the designated place.................................................................. 176

(5) Consumable replacement components............................................................................ 178

9. Error code list .................................................................................................... 179

10.Troubles and corrective measures .................................................................. 189

(1) Machine head ...................................................................................................................... 189

(2) Equipment and related matters ......................................................................................... 194

(3) Electrical matters................................................................................................................ 196