CONTENTS

1. SPECIFICATIONS............................................................................................................ 1

2. NAME OF EACH COMPONENT ..................................................................................... 2

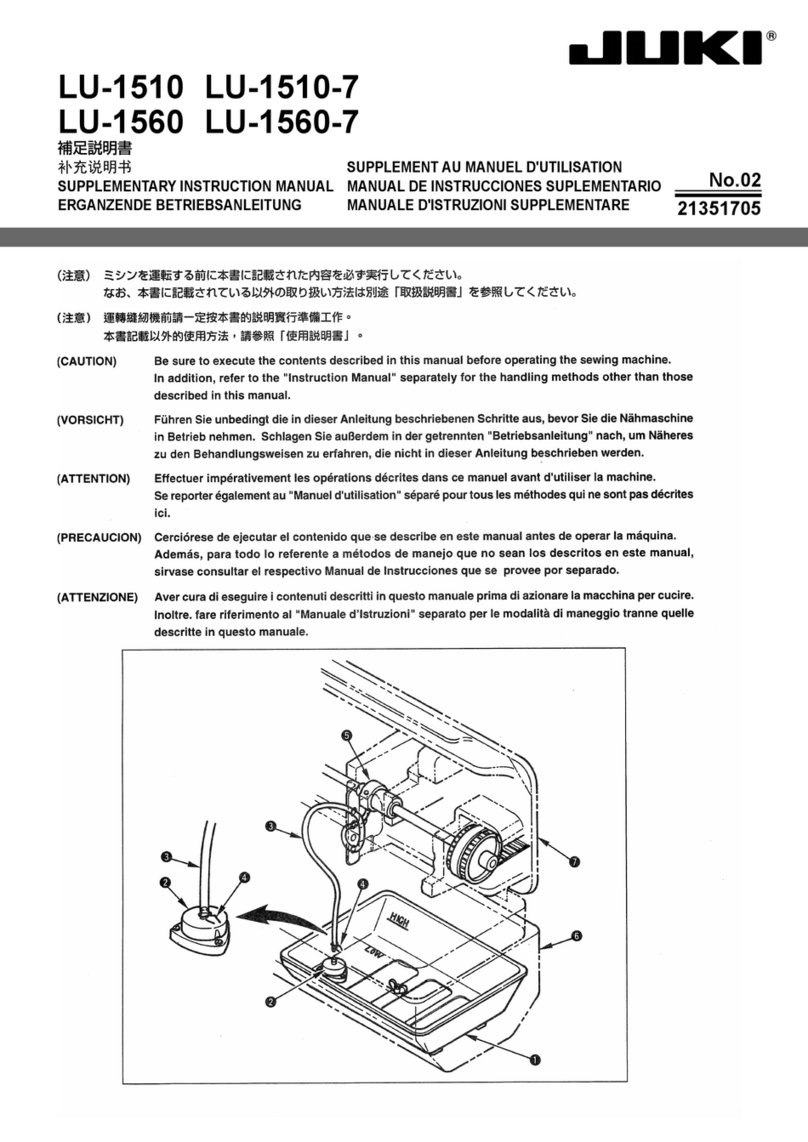

3. INSTALLATION................................................................................................................ 3

3-1. Caution at the time of set-up ................................................................................................................................ 3

3-2. Installation of the sewing machine ...................................................................................................................... 4

3-3. Adjusting the height of the knee lifter ................................................................................................................. 6

3-4. Installation of thread stand................................................................................................................................... 6

4. PREPARATION OF THE SEWING MACHINE ................................................................7

4-1. Method of lubrication ............................................................................................................................................ 7

4-2. Lubrication to the oil tank..................................................................................................................................... 8

4-3. Adjusting the amount of oil in the hook .............................................................................................................. 9

4-4. Oil in the feed box ................................................................................................................................................. 9

4-5. Applying grease................................................................................................................................................... 10

4-6. Installing the belt cover and the bobbin thread winder ................................................................................... 13

4-7. Attaching the needles ......................................................................................................................................... 13

4-8. How to take out the bobbin case ....................................................................................................................... 14

4-9. Insertlng a bobbin in a bobbin case .................................................................................................................. 14

4-10. Threading the machine head............................................................................................................................ 15

4-11. Thread tension ................................................................................................................................................... 16

4-12. Thread take-up spring....................................................................................................................................... 17

4-13. Adjusting the stitch length ............................................................................................................................... 18

4-14. Needle-to-hook relation .................................................................................................................................... 18

4-15. Adjusting the needle stop position.................................................................................................................. 20

4-16. Pedal pressure and pedal stroke ..................................................................................................................... 21

4-17. Adjustment of the pedal.................................................................................................................................... 21

5. OPERATION OF THE SEWING MACHINE .................................................................. 22

5-1. Pedal Operation ................................................................................................................................................... 22

5-2. Hand lifter............................................................................................................................................................. 22

5-3. Adjusting the pressure of the presser foot ....................................................................................................... 23

5-4. Micro-lifter ............................................................................................................................................................ 23

5-5. Thread tension release changeover when using the knee lifter ..................................................................... 24

5-6. One-touch manual reverse feed (One-touch reverse feed type)..................................................................... 24

6. MAINTENANCE ............................................................................................................. 25

6-1. Changing procedure to bottom feed and the adjustment ............................................................................... 25

6-2. Changing procedure to needle feed and the adjustment ................................................................................ 26

6-3. Adjusting the hook needle guard....................................................................................................................... 27

6-4. Adjusting the inner hook guide.......................................................................................................................... 27

6-5. Adjusting the height and the inclination of the feed dog ................................................................................ 28

6-6. Replacing the gauge ........................................................................................................................................... 29

6-7. Adjusting the thread presser spring.................................................................................................................. 30

6-8. Adjusting the position of the moving knife....................................................................................................... 31

6-9. Position of the wiper ........................................................................................................................................... 32

6-10. Caution when installing the attachments........................................................................................................ 32

6-11. Replacing the bobbin thread slack preventer sprlng (For LH-3568, 3568-7) ............................................... 33

6-12. Stop of the needle bars and angle of corners for corners stitching (For LH-3568, 3568-7) ....................... 33

7. STITCH-TO-ANGLE TABLE BY GAUGE (PITCH AND mm CONVERSION TABLE).. 34

8. GAUGE SETS................................................................................................................ 35

9. TROUBLES AND CORRECTIVE MEASURES ............................................................. 40

10. MOTOR PULLEY AND BELT ...................................................................................... 41