CONTENTS

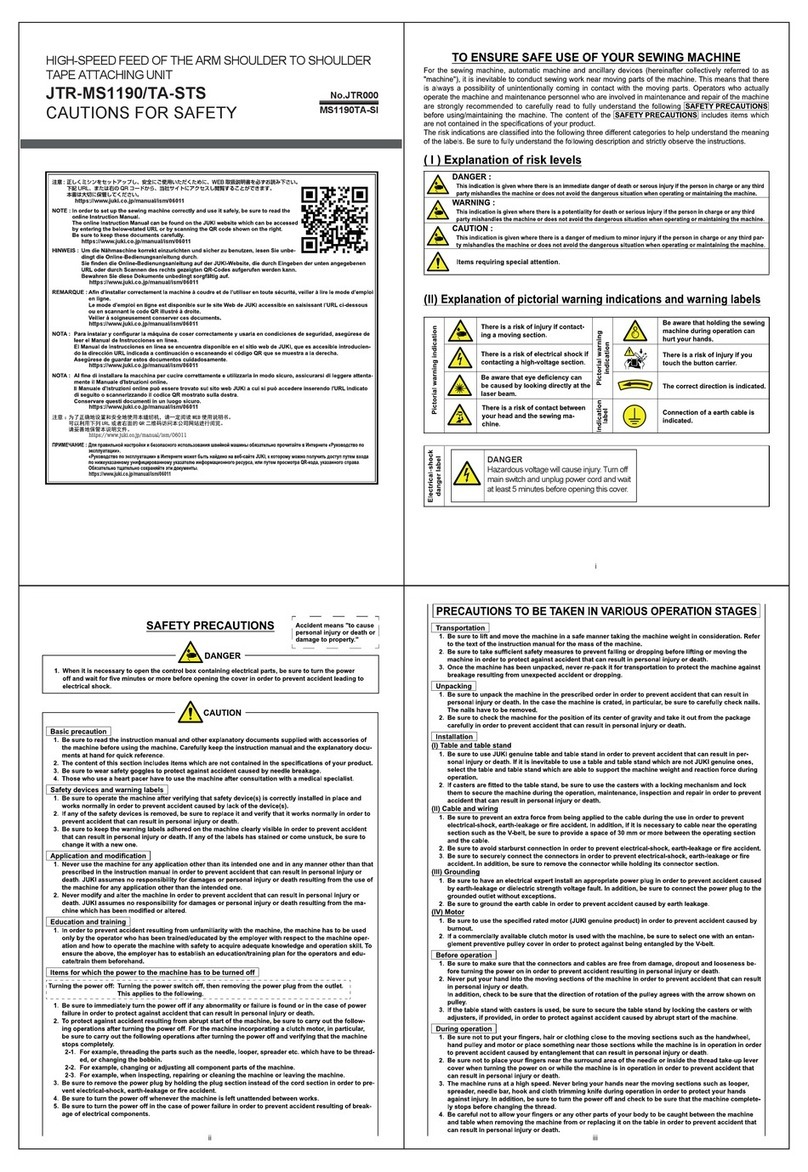

Safety Matters for Attention .......................................................................... i

1. Signs & Denitions of Safety Marks ......................................................................... i

2. Safety Matters for ttention.......................................................................................... i

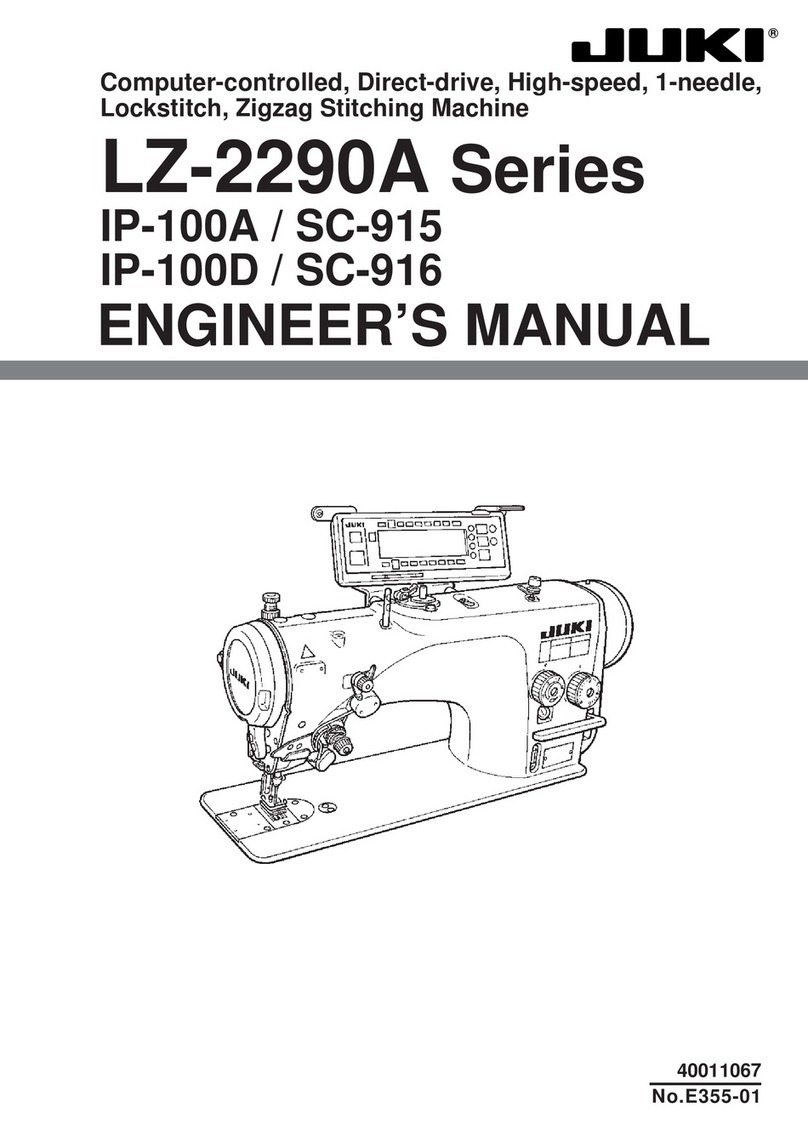

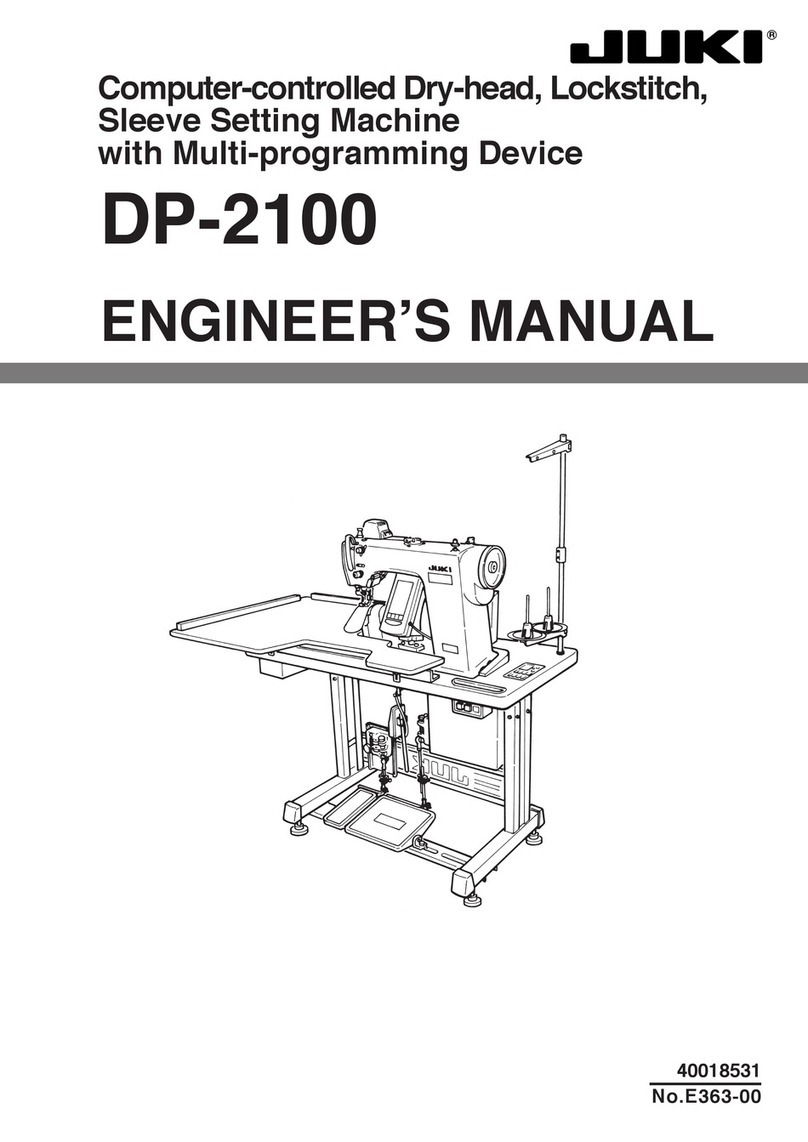

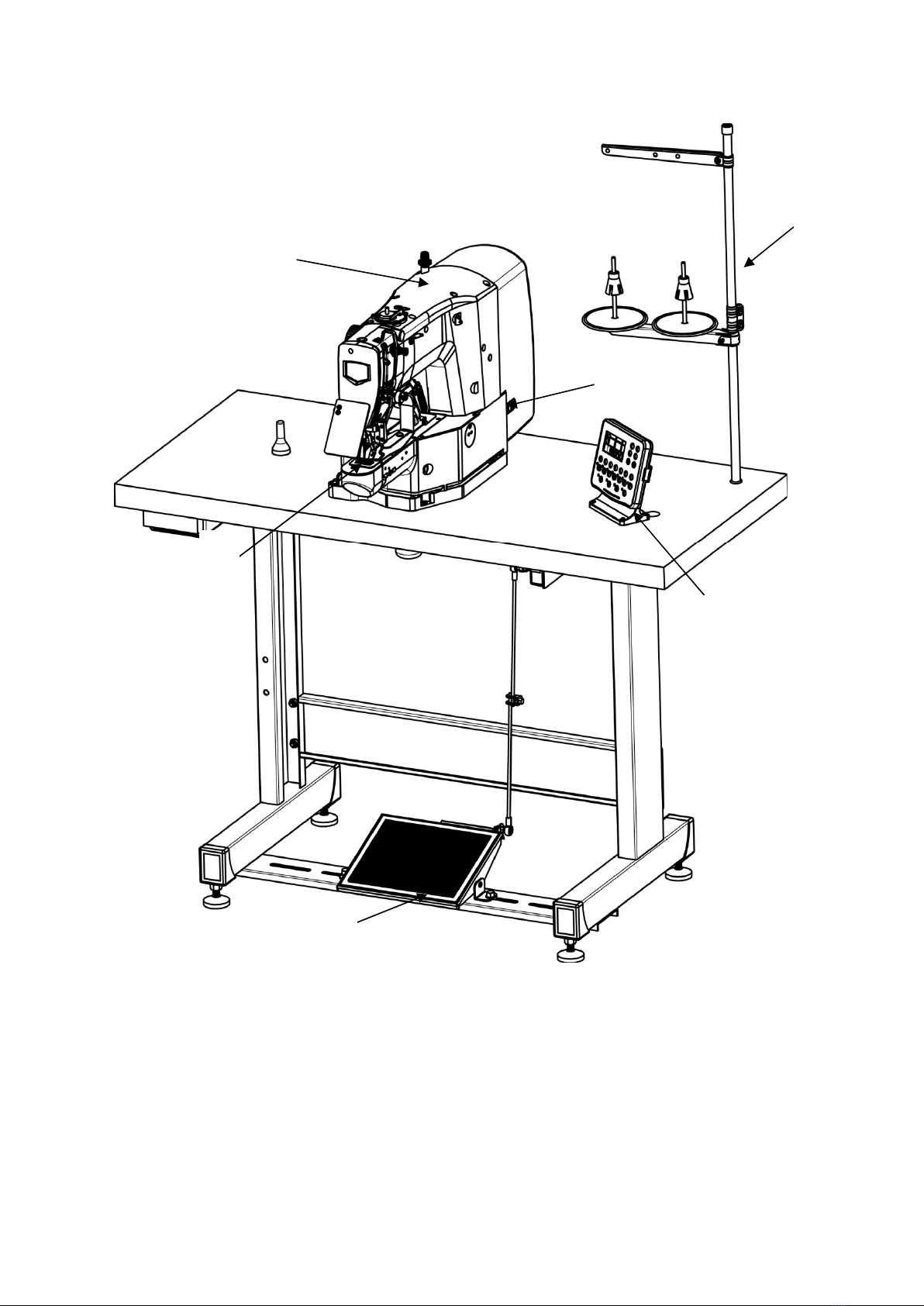

I. INSCAPE...................................................................................................... 1

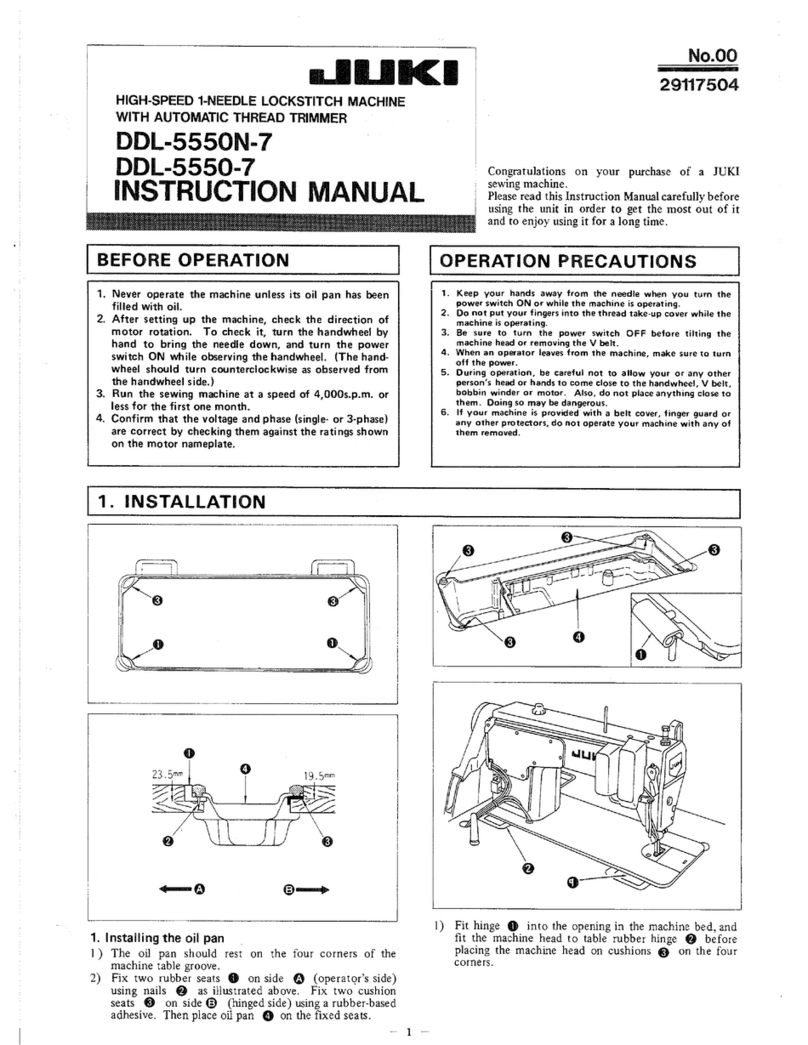

II. INSTALLATION........................................................................................... 2

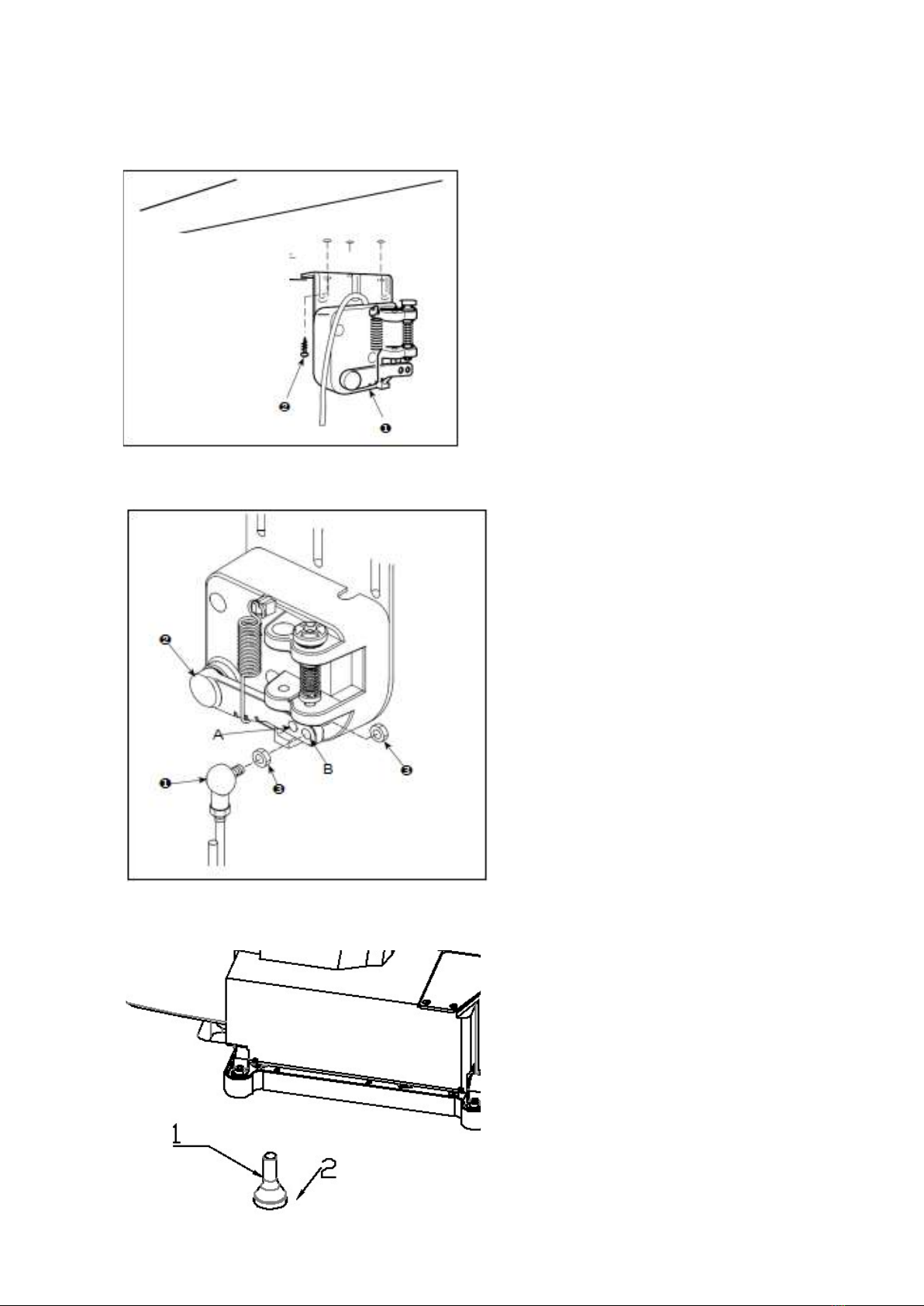

1. Installing the pedal sensor........................................................................................ 2

2. Attaching the connecting rod ................................................................................... 2

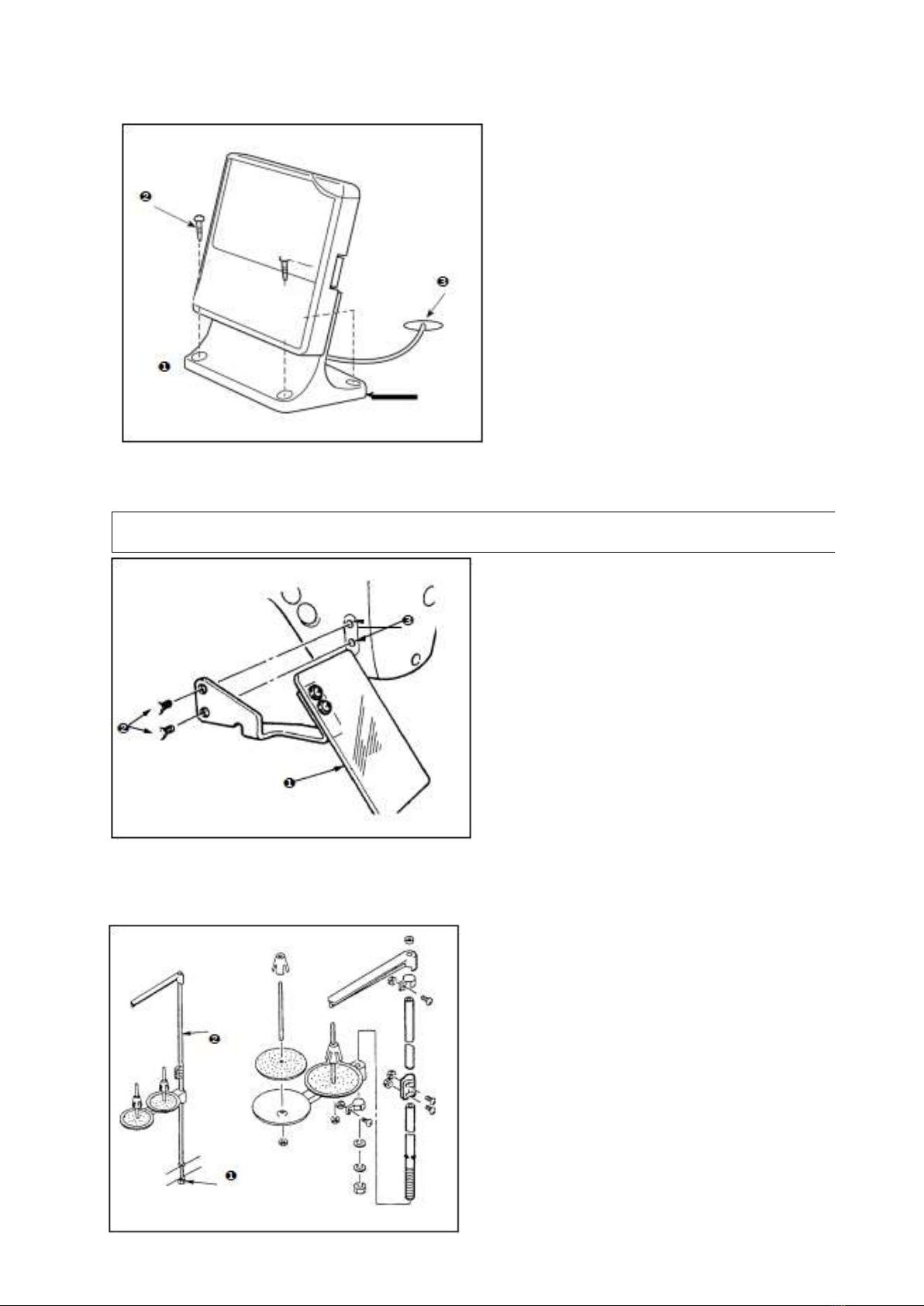

3. Installing the head support rod ................................................................................ 2

4. How to carry the sewing machine ............................................................................ 3

5. Installation of the sewing machine head ................................................................. 3

6. Installing the drain receiver and the head support rubber .................................... 4

7. Tilting the sewing machine head.............................................................................. 4

8. Installing the operation panel ................................................................................... 5

9. Installing the eye protection cove ............................................................................ 5

10. Installing the thread stand ...................................................................................... 5

III. OPERATION OF THE SEWING MACHINE............................................... 6

1. Lubrication.................................................................................................................. 6

2. Attaching the needle .................................................................................................. 6

3. Threading the machine head .................................................................................... 7

4. Installing and removing the bobbin case ................................................................ 7

5. Installing the bobbin .................................................................................................. 8

6. Adjusting the thread tension..................................................................................... 8

7. Adjusting the thread take-up spring......................................................................... 8

8. Example of the thread tension.................................................................................. 9

IV. MAINTENANCE......................................................................................... 9

1. Adjusting the height of the needle bar..................................................................... 9

2. Adjusting the needle-to-shuttle relation ................................................................ 10

3. Adjusting the lift of the work clamp foot................................................................ 11

4. The moving knife and counter knife....................................................................... 11

5. Draining waste oil .................................................................................................... 12

6. Amount of oil supplied to the hook ........................................................................ 12