CONTENTS

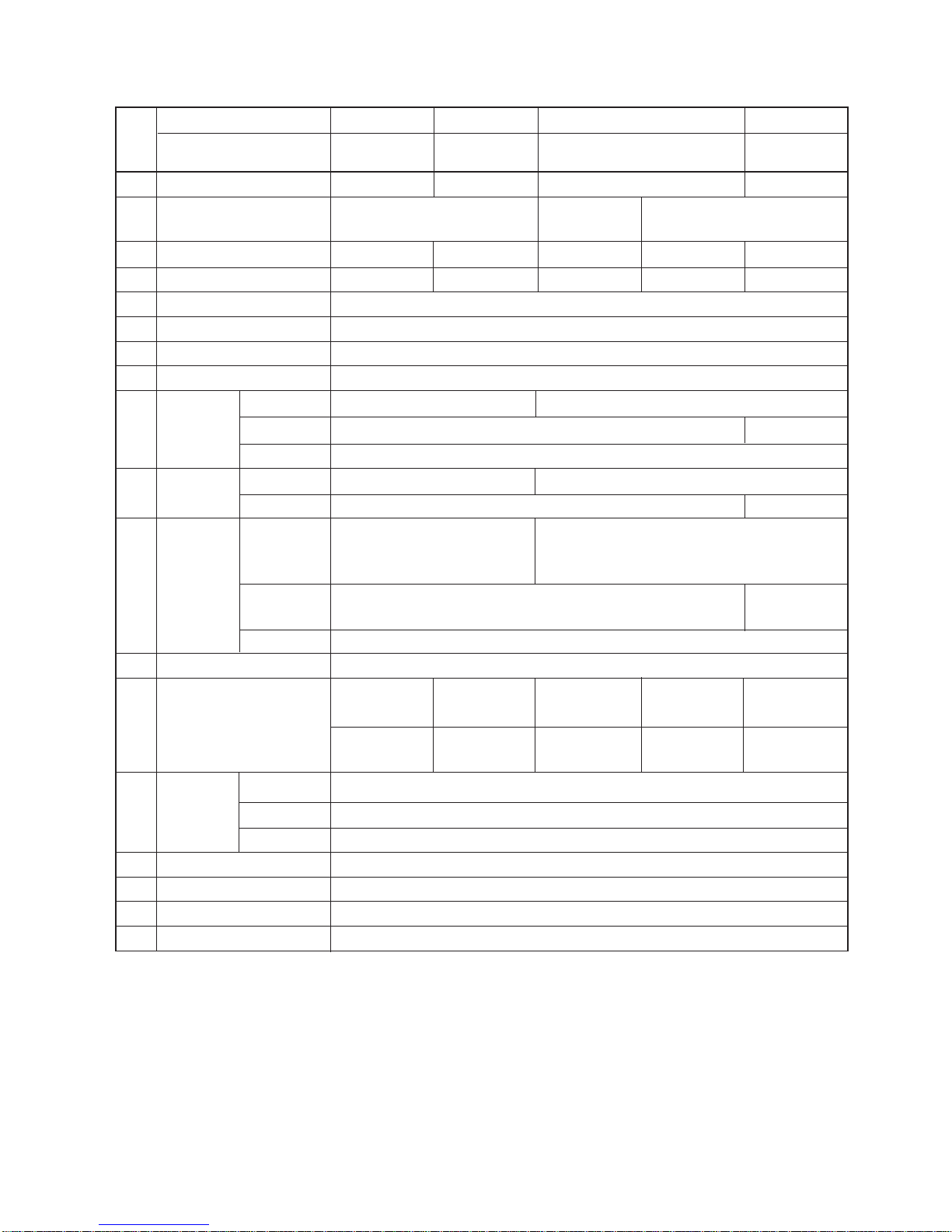

1. Specifications ............................................................................................... 1

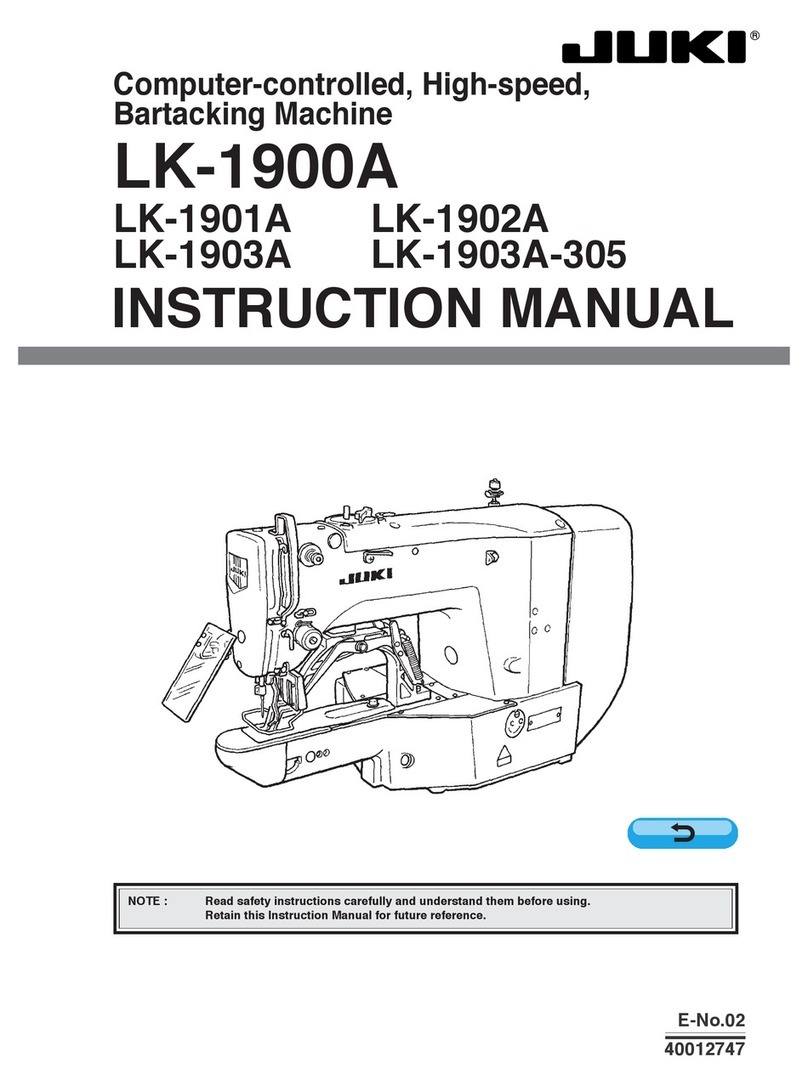

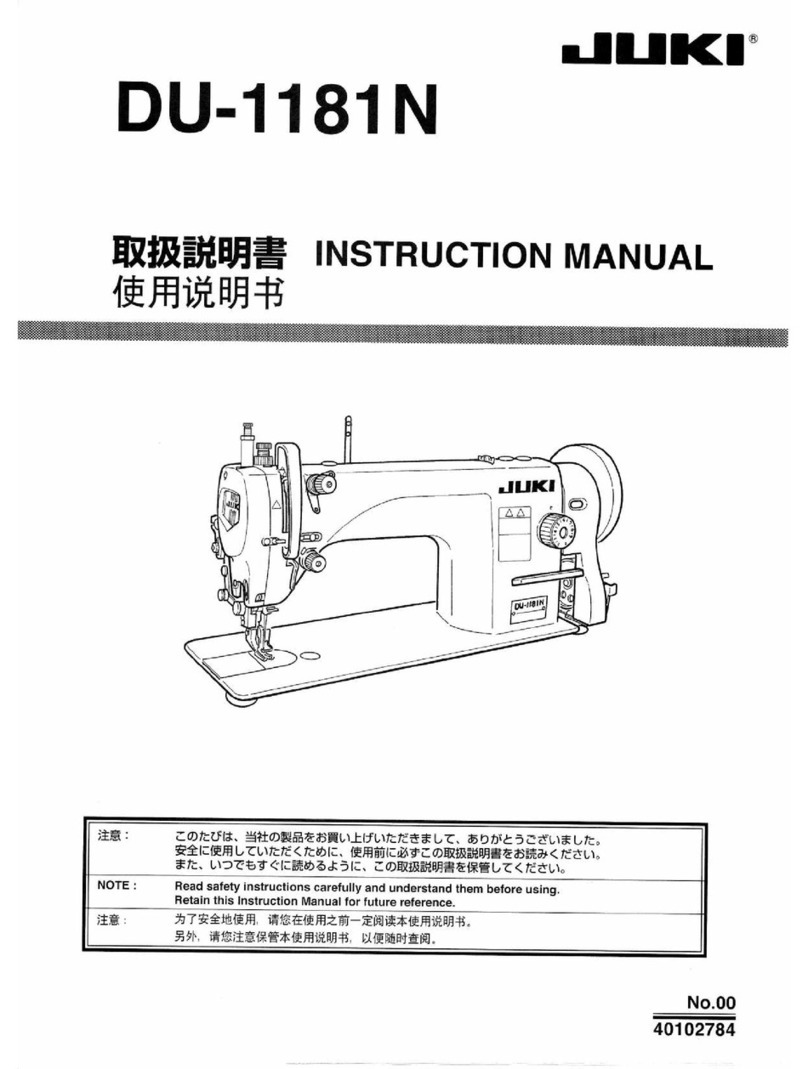

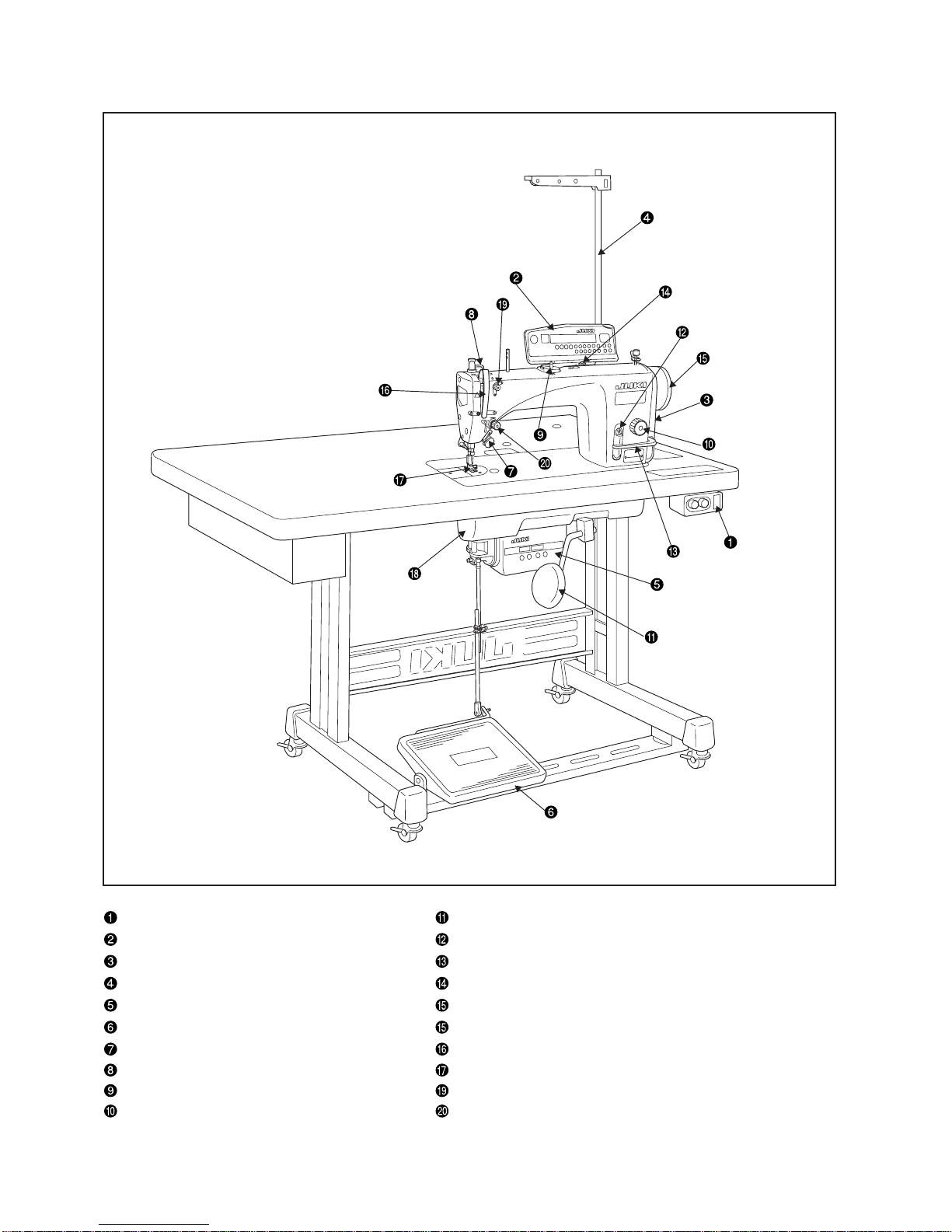

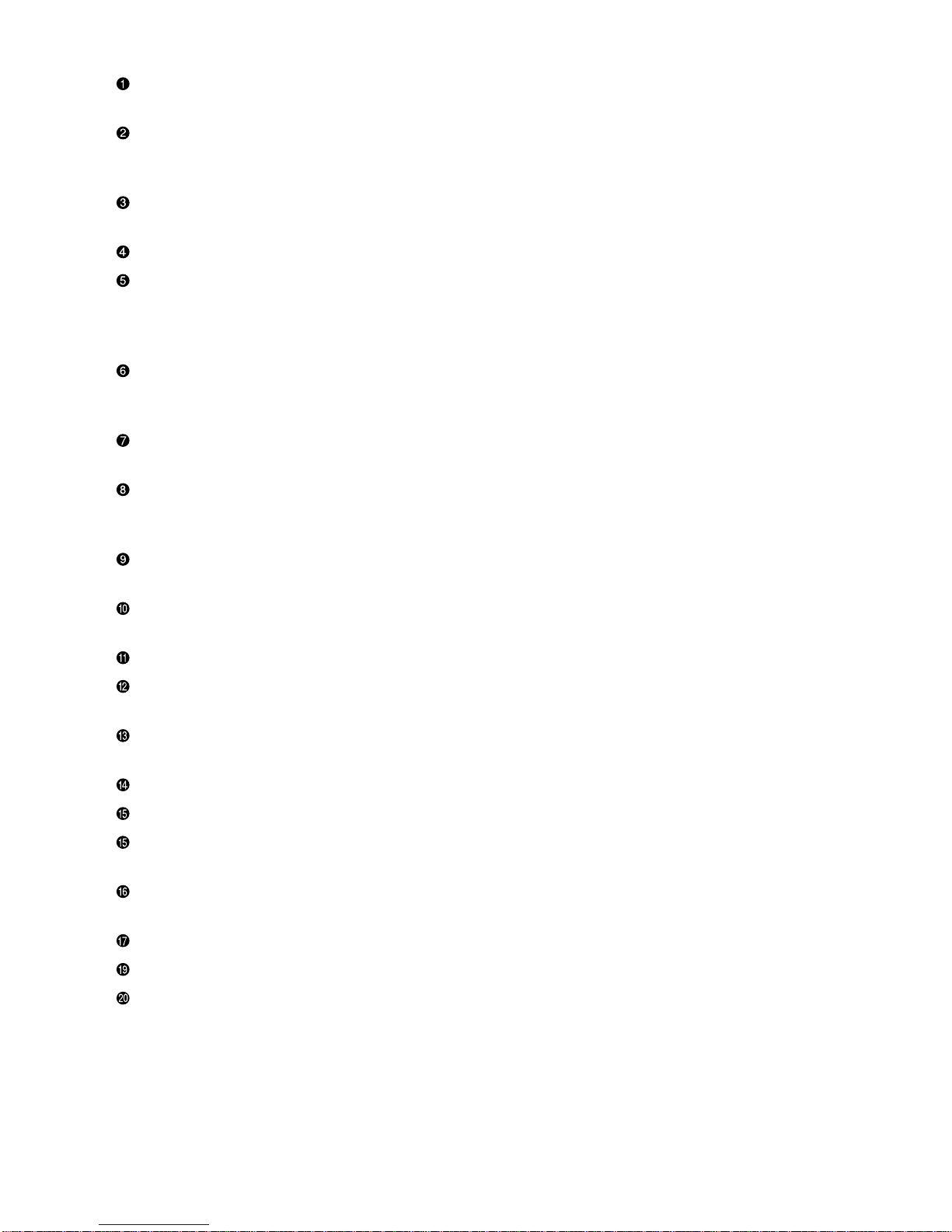

2. Name of each component ............................................................................ 2

3. Standard adjustment .................................................................................... 4

(1) Feed dog height and gradient ...................................................................................4

(2) Timing for the needle and the inner hook ................................................................6

(3) Needle and feed timing ..............................................................................................8

(4) Feed locus and phase ..............................................................................................10

(5) Bobbin insertion .......................................................................................................12

1) Bobbin case with idling prevention spring ..................................................................................12

(6) Adjustment of inner hook presser position ...........................................................14

(7) Lubrication ................................................................................................................16

1) Method of lubrication .....................................................................................................................16

2) Method of lubrication to the oil tank.............................................................................................18

3) Method of oil drainage from the oil tank ......................................................................................18

4) Cleaning of the oil filter..................................................................................................................20

5) Oil in the gear box ..........................................................................................................................22

6) Placement/displacement of the gear box cover ..........................................................................22

7) Cautions for gear box cover oil during transportation ...............................................................22

8) Adjustment of hook oil quantity....................................................................................................24

9) Hook oil adjustment procedures...................................................................................................24

10)Essentials for hook oil adjustments .............................................................................................24

11) Replacement of the hook shaft oil wick .......................................................................................24

(8) Adjustment of the amount of feeding .....................................................................26

1) Adjustment of forward feed stitch length.....................................................................................26

2) Adjustment of reverse feed stitch length (manual) .....................................................................26

3) Adjustment of reverse feed stitch length (motor-power)............................................................26

4) Optional switch ...............................................................................................................................28

5) Adjustment of normal/reverse stitching.......................................................................................30

6) Adjustment of Feed 0 .....................................................................................................................30

1. Method by removing the gear box cover (standard adjustment) .................................................30

2. Method without removing the gear box cover (fine adjustment).................................................32

7) Adjustment of the feed dial section ..............................................................................................34

8) Adjustment of the reverse feed solenoid .....................................................................................36

9) Adjustment of feed changing shaft balancer arm (asm) positioning ........................................36

(9) Adjustment of the presser lifter ..............................................................................38

1) Adjustment of the presser pressure .............................................................................................38

2) Adjustment of thread release changeover ...................................................................................38

3) Adjustment of the micro-lifter .......................................................................................................40

4) Adjustment of the micro-lifter unit (available separately) ..........................................................40

(10) Adjustment of needle stop position........................................................................42

1) Adjustment of upper stop position (Stop position after thread trimming) ................................42

2) Adjustment of lower stop position ................................................................................................42

(11) Thread trimming unit................................................................................................44

1) Standard timing for the thread trimming cam..............................................................................44

1. Method of confirmation ................................................................................................................45

2. Method of adjustment ..................................................................................................................45

2) Correct position of the moving knife ............................................................................................46

1. Extreme backward position .........................................................................................................47

2. Initial position...............................................................................................................................47