The sewing machine has adopted a feed mechanism which keeps

the ratio between the amount of the vertical movement of the walking

foot and that of the presser foot constant even when the material is

changed. The amount of the alternating vertical movement of the

walking foot and the presser foot is 9 mm at the maximum. This

amount can be set with ease by means of the large dial installed on

the upper section of the sewing machine.

A presser bar height of 20 mm is achieved when using the automatic

presser bar lifting lever. Thanks to this feature, the process of joining

leather and heavy-weight sponges, which are usually used as

materials for expensive sofas, can be carried out with ease.

Adjustable screw

Subclass

Thread trimming can be stable even at the maximum 12mm sewing length.

The hook which can be adjusted with screw amout of needle guard

contact to needle. The needle guard can be easily adjusted.

Therefore, it prevents stitch skipping and wear of hook edge.

Walking-foot/presser-foot alternating vertical

movement mechanism prevents irregular stitches Higher lift of the presser bar

Walking-foot/presser-foot alternating vertical

movement mechanism prevents irregular stitches

New mechanism of thread trimmer

Single or Double can be set easy

through Multi-functional 6-string switch,

regarding the machine with trimmer.

(Available for more thick material)

In addition to the one-touch type reverse

feed switch, a multi-functional 6-string

switch is also provided. Changeover of

the amount of the alternating vertical

movement of the walking foot and the

presser foot and changeover of the stitch

length can be done simply with this one

push.

Multi-functional 6-string switch

(with automatic thread trimmer)

Double tension provided as : standard

New bobbin thread spool device is no neccessity of rolling thread

manually.

New bobbin thread spool device

Oil does not flow backwards by a valve system. Therefore, oil can be

supplied certainly even low speed. Thanks to the stable lubrication to

the hook, it produces beautiful seams.

New lubrication system

The upper and lower feed ratio can be changed only by the

adjustment of the lower feed amount without changing the upper

feed amount, thereby preventing material slippage.

The upper and lower feed ratio is adjustable

Adjustment of the eccentricity of the feed driving cam has been

enabled. As a result, the sewing machine is able to perform sewing

with the feed that is best-suited to the material and thread used. It is no

longer necessary to prepare other subclass model sewing machines.

Eccentricity of the feed driving cam is adjustable.

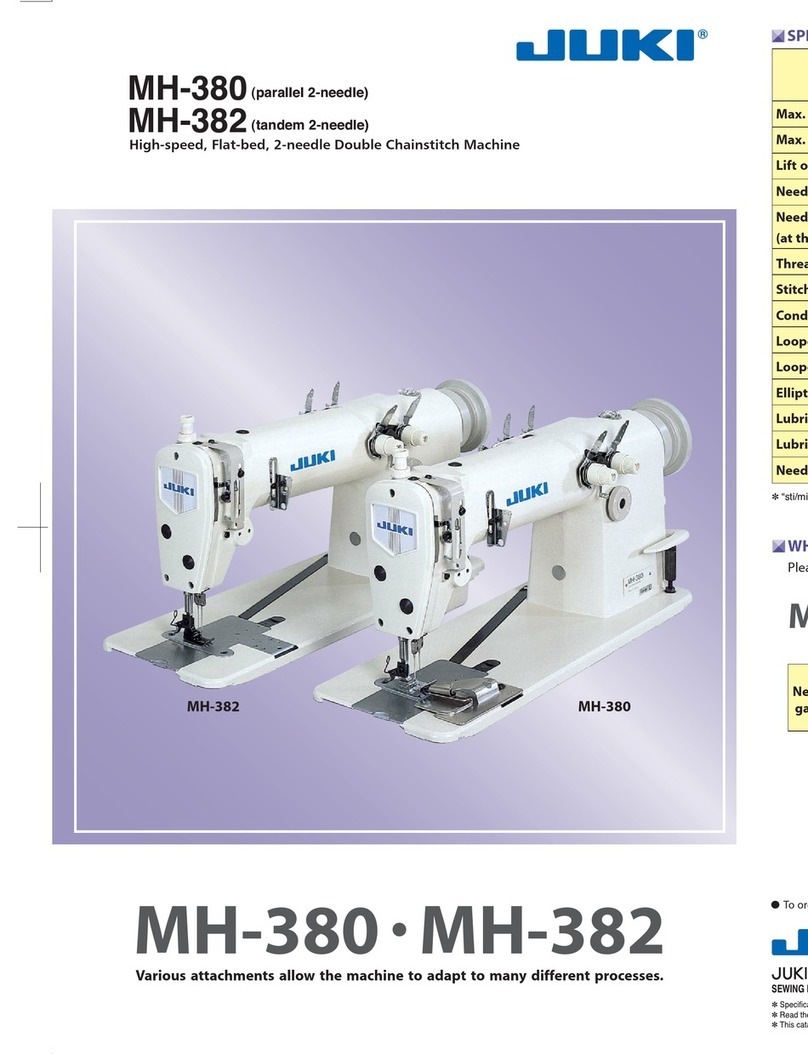

2-needle, Post-bed, Unison-feed, Lockstitch Machine

with Vertical-axis Large Hook (Thick-thread type)

PLC-2760L

2-needle, Post-bed, Unison-feed, Lockstitch Machine

with Vertical-axis Large Hook (Organized split needlebars type)

With its organized split needlebars, the machine

produces well-balanced topstitch-seams

even at the corners of materials such as sofas.

PLC-2765

The machine is able to perform sewing with low-count thread under

a higher tension, which is difficult for the conventional single-tension

method, with ease. The machine comes with a dual-tension thread

tension system.

Thanks to the hook, thread-take up and gauges

exclusively designed for PLC-2760L, the machine

can sew with thread count up to #6. The machine is

provided with the exclusive top and bottom feed

locus ideal for sewing with thick-thread.

PLC-2760L PLC-2765