–7 –

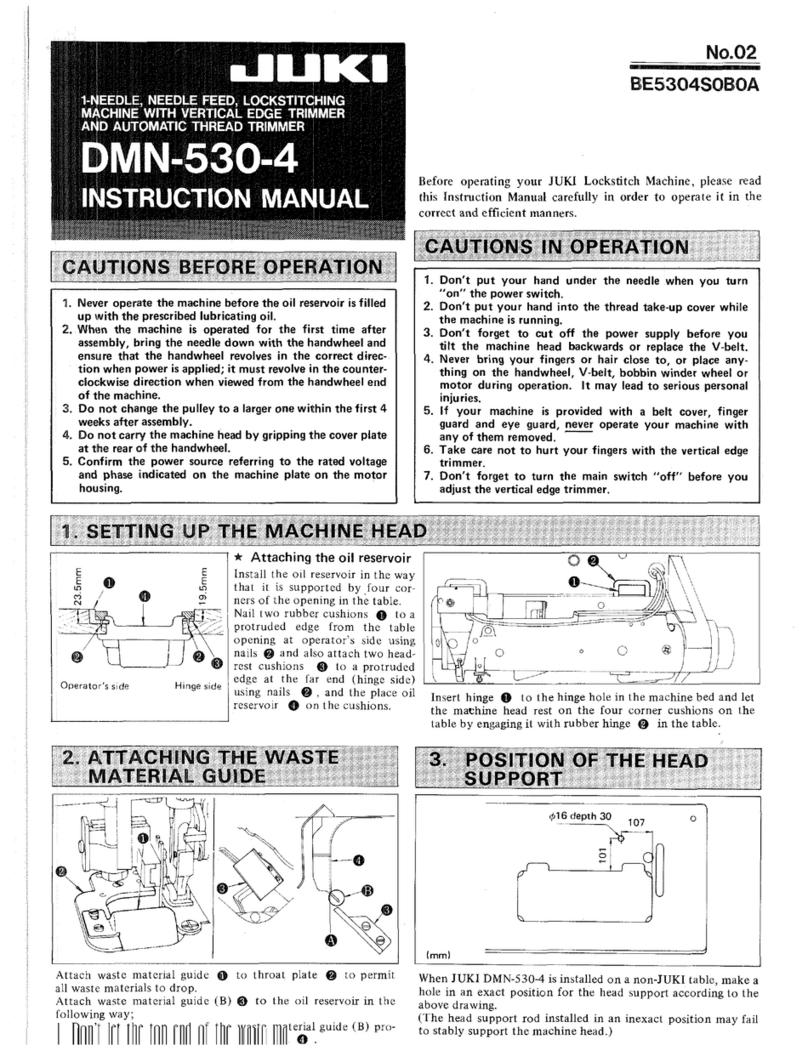

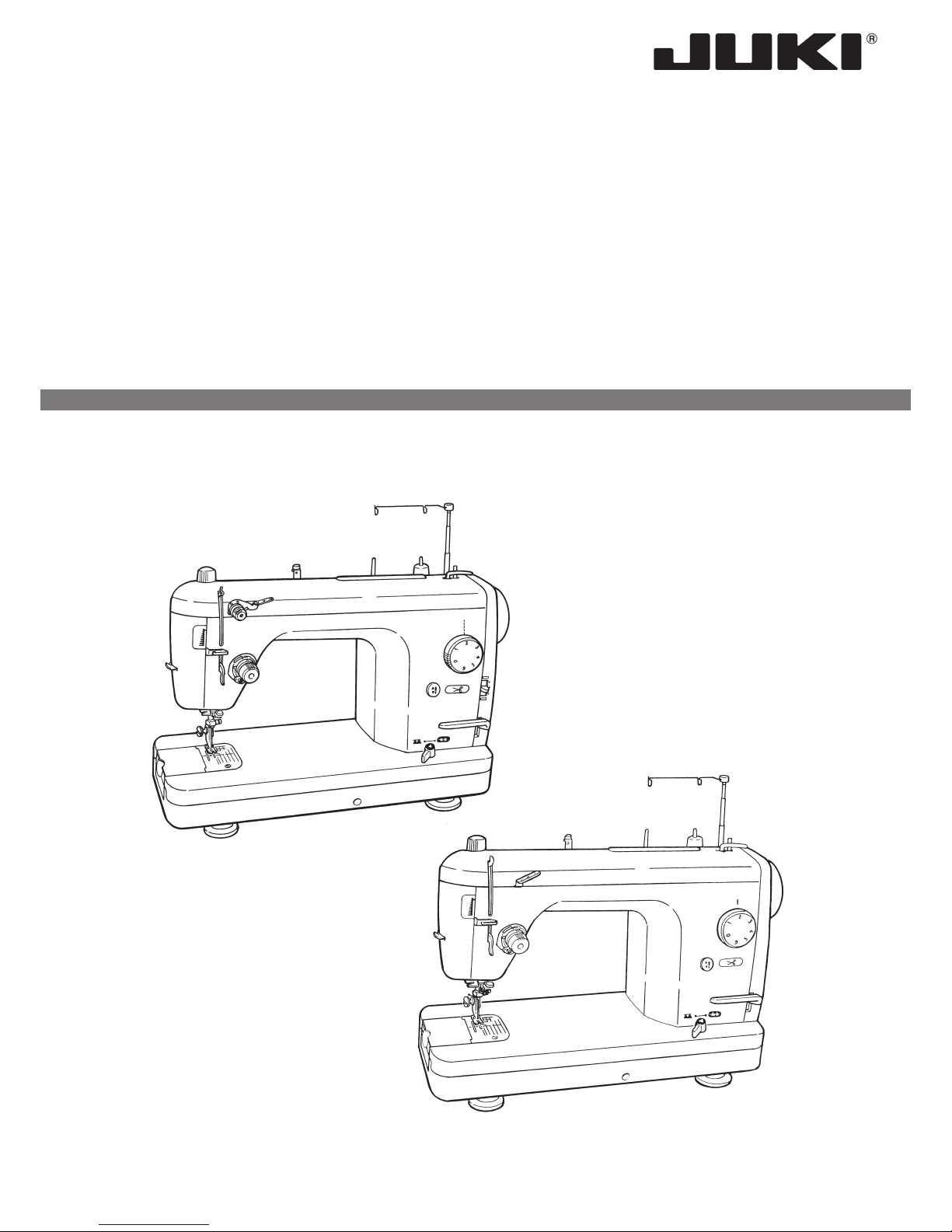

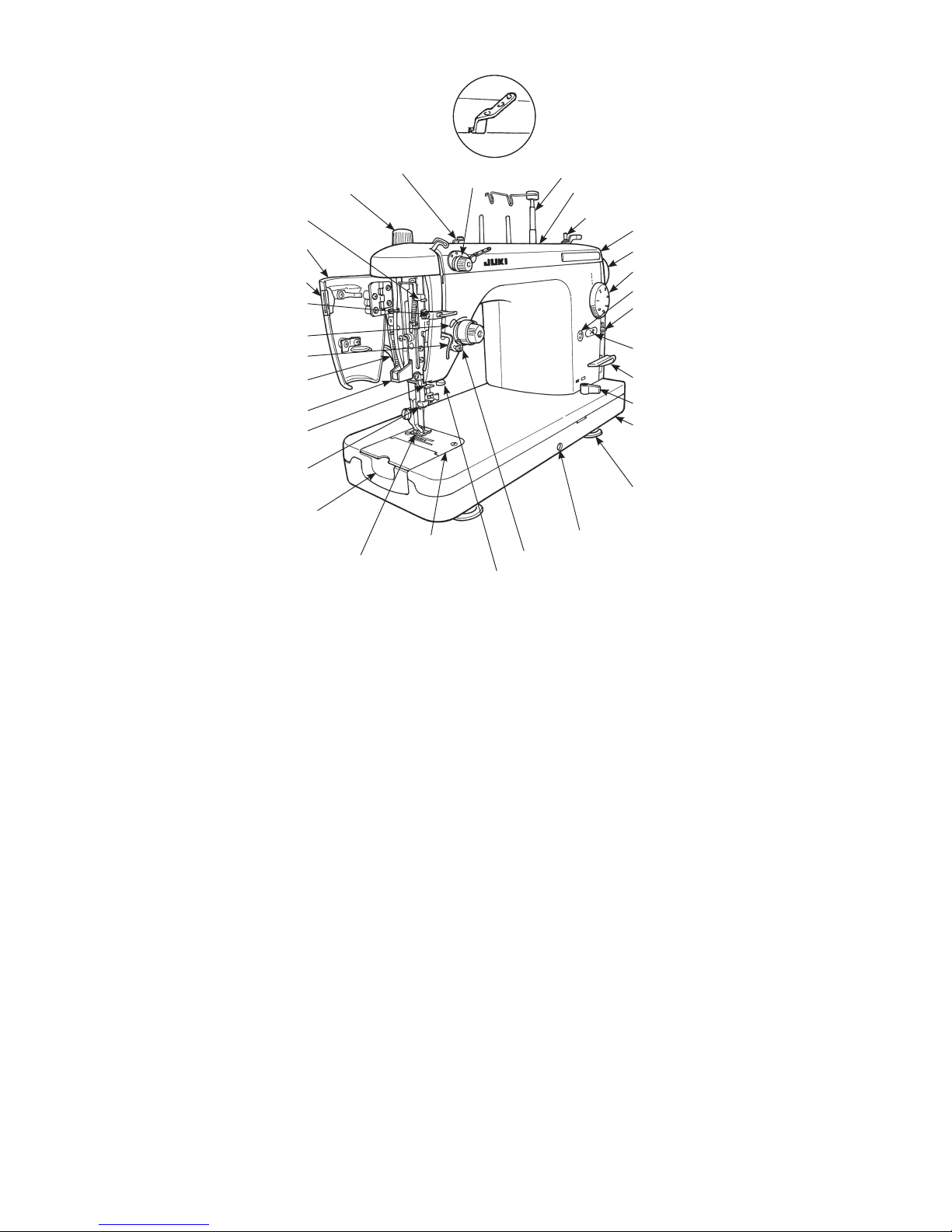

4. Presser bar

Preparation

™Remove arm cover asm.

™Remove face plate mas. asm.

™Remove presser foot and setscrew.

Disassembly

™Lower 8lever and loosen 1set-

screw.

™Drawing 3u p w a r d , r e m o ve 4

spring.

™Remove 5connection and 6lever.

™Remove regulator 2screw.

™Do not remove 7indicating needle.

3is hard to remove since secrew

mark is attached.

Assembly

™Attach regulator 2screw.

™Set 6lever to frame, and then

set 5connection.

™Attach 4spring when setting

3presser bar from upper side.

Point

™Set 4spring under 7indicating

needle.

™Lower 8lever and temporarily

tighten it at the position where top

end of 3protrudes approximately

4 mm from frame.

For the adjustment, see item 3 on

page 17.

™Needle should not interfere with

presser foot.

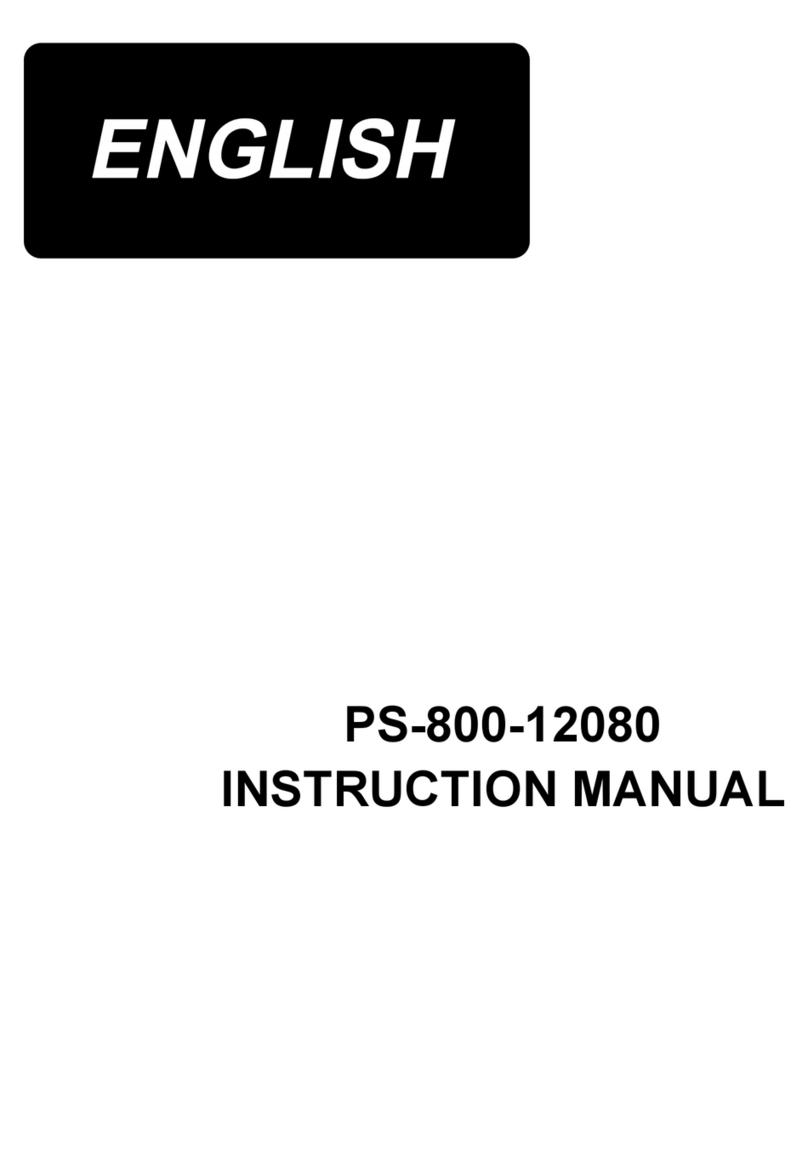

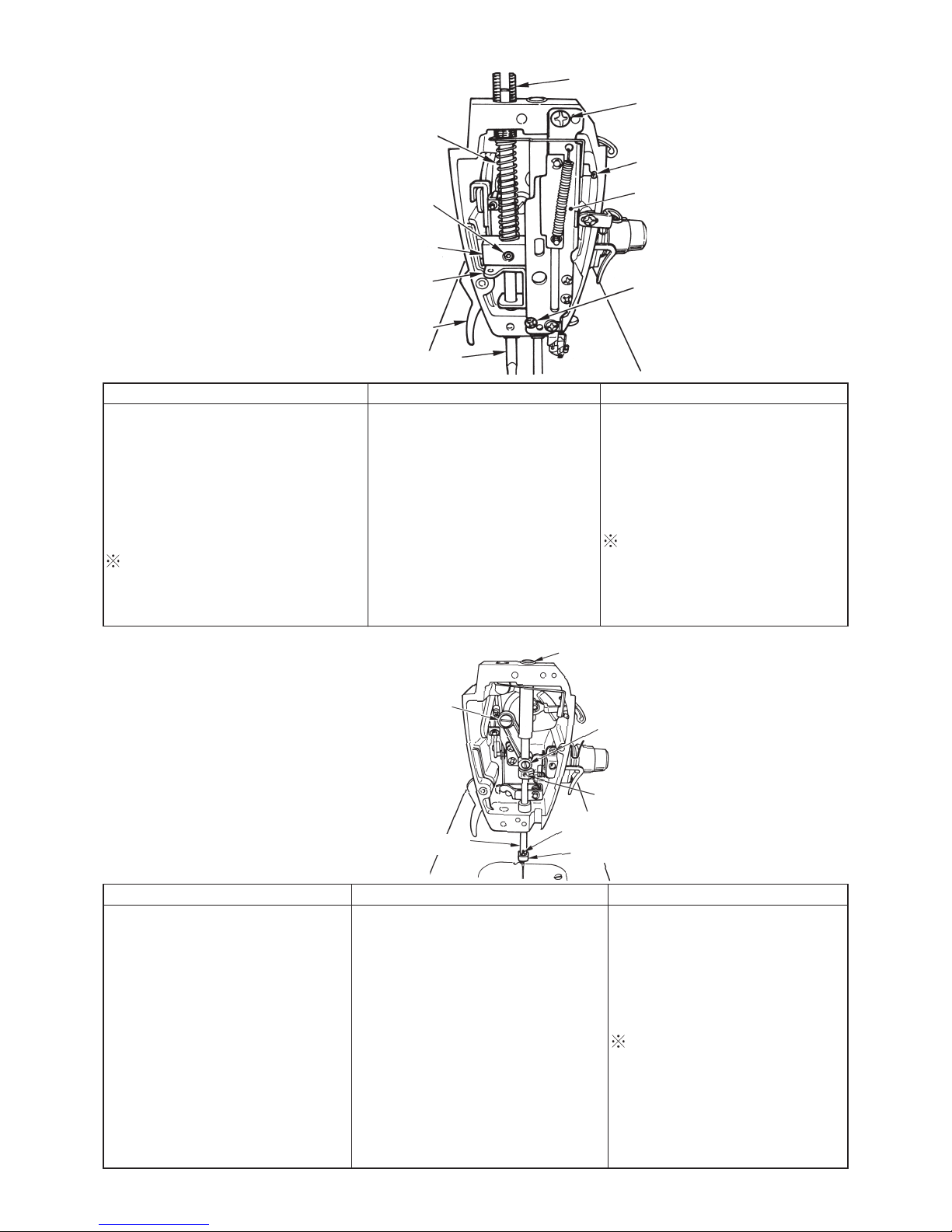

Disassembly

™Remove 3and 4.

™Remove 1felt. (Push up needle

bar upper bushing 1felt with 5

and draw it out.)

™Loosen setscrew of 2and 6.

(Pushing needle bar 5upward is

acceptable.)

™Draw out 5upward.

™Remove left 6screw and remove

crank rod.

Assembly

™Attach crank rod and tighten it with

6.

™Perform positioning of needle bar

and tighten needle bar connection

2setscrew.

™Set needle bar and attach 4and

3.

™Insert 1into hole.

™Temporarily tighten 6, and perform

adjustment of vertical height after

attaching threader support plate

asm.

Point

™Position of needle bar is the

place where upper engraved

line of needle bar is aligned

with lower end face of needle

bar bushing at the needle lower

dead point.

See item 2 on page 17 for the

adjustment.

™See item 15 o n page 22 for

height adjustment of threader

hook of threader support plate

mas. asm.

6Presser bar lifting lever

8Hand lifter lever

3Presser bar

2Presser spring regulator

7Indicating needle of

presser spring regulator

4Presser spring

5Presser bar connection asm.

1Presser bar connection setscrew

SM8060502TP

Threader support plate

setscrew (upper)

SL5040631SE

Threader support plate mas. asm.

Threader support plate

setscrew (lower)

SM4040655SN

5. Needle bar

Preparation

™Remove arm cover asm.

™Remove face plate mas. asm.

™Remove presser bar.

™Remove needle bar threading

guide as well.

Needle bar crank

left screw

1Needle bar upper bushing felt

2Needle bar connection setscrew

SM8060510SP

6Needle bar threader guide setscrew

5Needle bar

3Needle bar thread bracket

setscrew A1420-001-000

4Needle clamp