5

86/87R Compressor System User Guide 6190755 (Rev A)

© 2015, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

• Install product on a rigid level surface maintaining a minimum of 6 in/15

cm clearance all around the unit and a 12 in/30 cm clearance above the

system.

• Sufficient cooling from the surroundings is important. Place the system

in a dustfree, dry and cool, yet frostfree, room. Do not install in a closed

cupboard, unless adequate openings for ventilation are available on top

and bottom (minimum 500 cm²/77.5 in² each). If the system is placed

under a table, a minimum of 12 cm/5 in free height must be available

above the system or an opening of Ø30cm/11.8 inches, corresponding

to the top of the system, may be cut in the table. Ensure that the system

stands firmly on the floor.

• The intake air may be supplied from another place (for instance outside).

Ensure that hoses for the intake are sufficient to avoid performance loss

and that any alternate filter used has the same micron rating (50μm) as the

JUN-AIR intake filter.

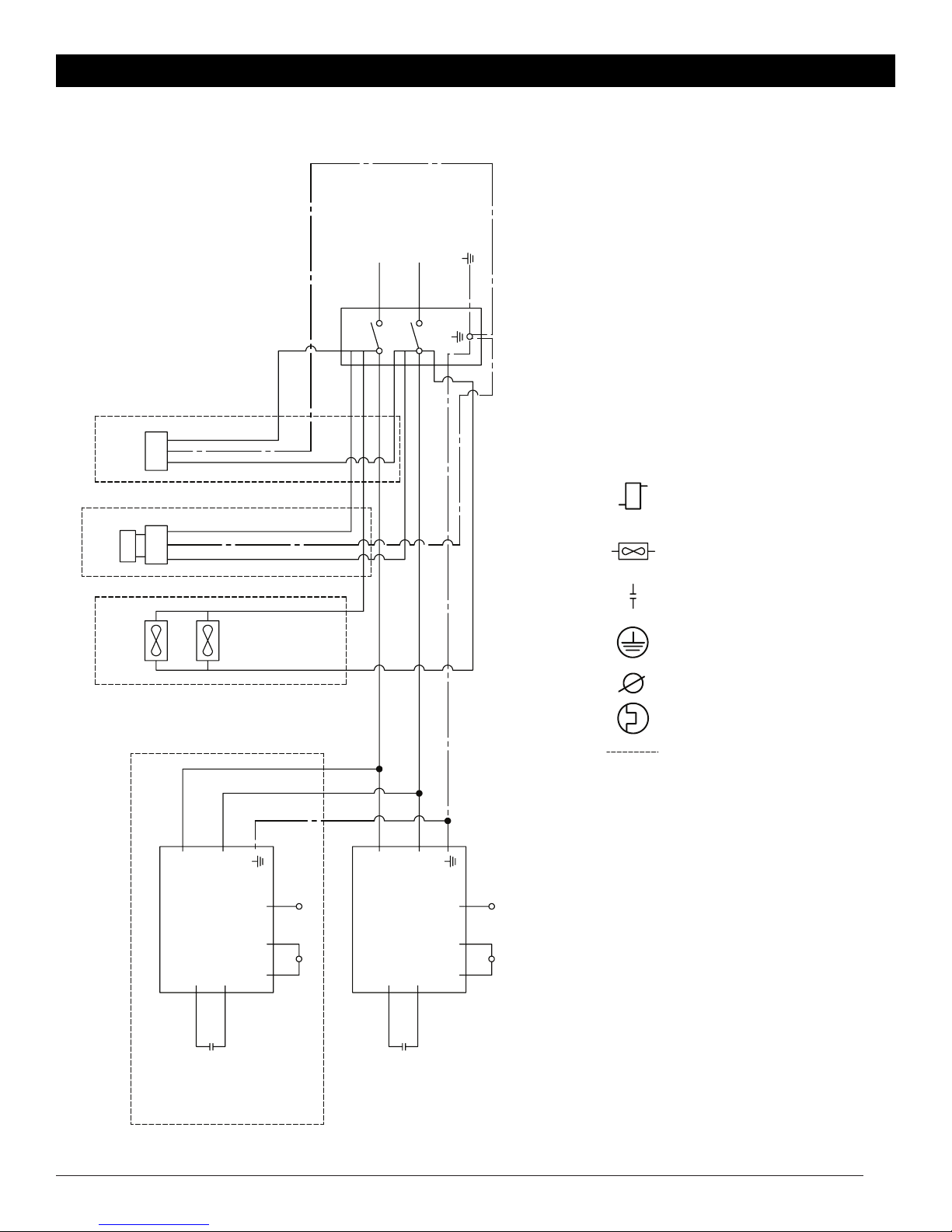

Electrical installation

Warning!

Incorrect electrical connection may result in electric shock. The

electrical connection must be carried out in accordance with

local electrical regulations and by qualified electrical engineers.

Note!

Earthing of all AC models must be ensured during installation. The capacitor

must be earthed, as failure to do so may cause electric shock when touched.

Plug the system into an earthed socket of nominal voltage and ensure that

fusing is adequate.

AC models

• For electrical connection, refer to schematic in back of this manual.

• Check system serial number label for frequency and voltage to ensure

that it corresponds to the voltage and frequency used for the system. The

voltage stated on the system plate: 120/240V (/) means that the system

can operate at 120V or 240V, but this requires recoupling of the internal

wiring from the electrical system (see the electrical diagrams). 220-230V

(-) means that the system may operate within the range of 220V to 230V

without recoupling of the internal wiring.

• Capicitor is wired to motor via terminal box on side of motor.

• Accessorries are wired through the system pressure switch.

Operation

• If the temperature of the system is extremely low (for instance after

transportation or stocking), allow system to get to room temperature before

switching on the system.

• Do not use system for compression of liquids and dangerous gasses,

such as petrol vapour and solvents.

Important

This system is only suitable for atmospheric air.

• Do not remove protection covers during operation as it may cause electric

shock or risk of other personal injury (ie: terminal box, pressure switch).

• Ensure that system is correct for air supply flow required, see Technical

Specifications.

• Open the outlet cock on the receiver and connect equipment.

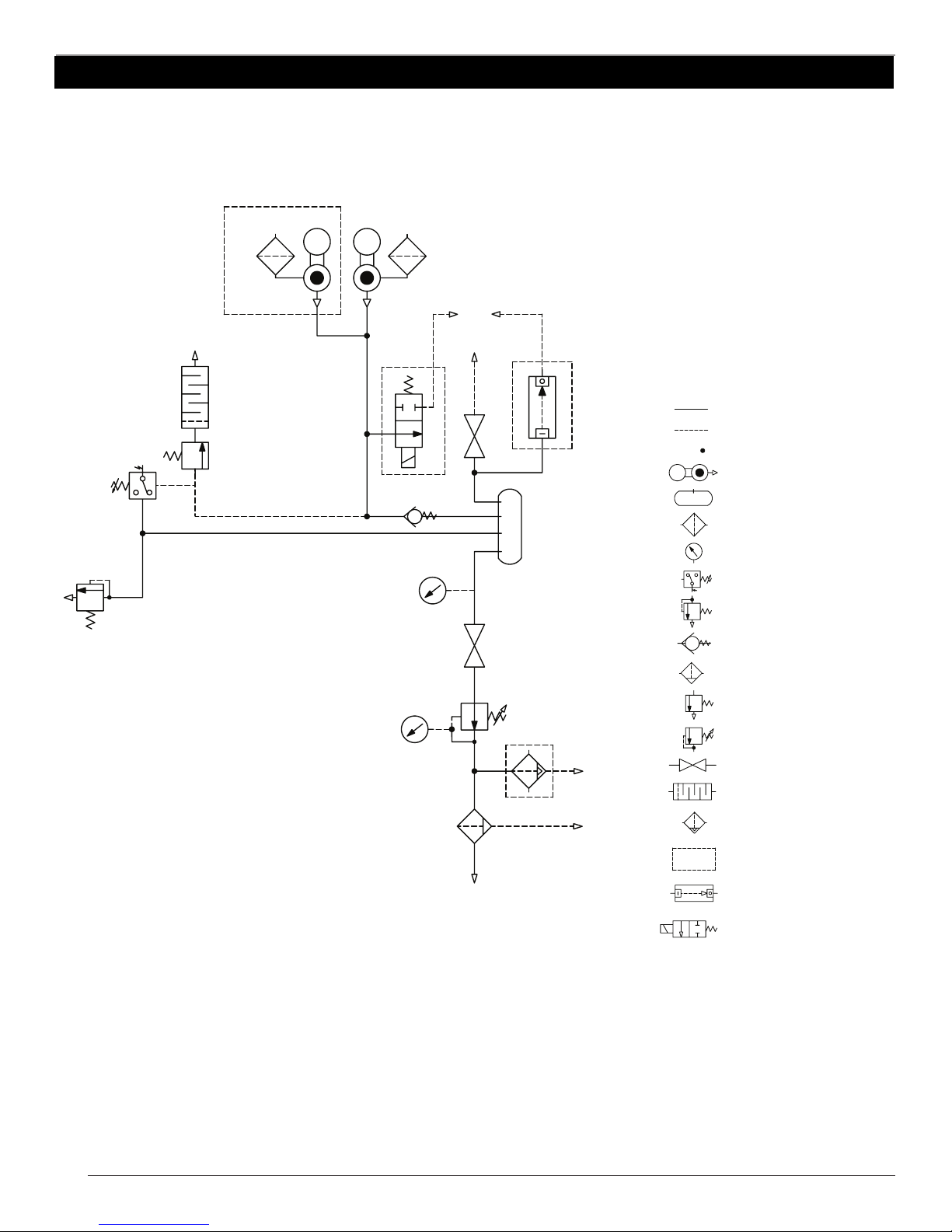

Adjustment of pressure switch

Warning!

If maximum pressure is exceeded, reduced lifetime may result.

Contact JUN-AIR for information on operation at higher

pressure.

• All systems may run at 100% continuous operation, but 50% operation is

recommendable to prolong lifetime.

• The system should be sized so that the tank is capable of supplying air

100% of the time and the compressors only run at 50%.

• Do not lubricate the oil-less system with oil, as this will destroy important

components.

• Start the system using the 0/1 switch on the pressure switch. The system

will automatically switch off at the preset pressure. If the system does not

start it may be due to pressure in the receiver, and the system will then

start automatically when the pressure reduces to approx. 6 bar/87 psi.

• Adjustment of pressure (see back of manual)

A: Max. pressure adjustment (cut-out)

B: Differential adjustment (cut-in)

The cut-in pressure (normally 6 bar) is set by adjustment of differential

screw B. Turn clockwise to reduce cut-in pressure. The cut-out pressure is

set by even adjustment of the two screws A. (Cut-in pressure + differential

= cut-out pressure). Turn clockwise to increase cut-out pressure. The

switch is normally factory set for operation at 6-8 bar (approx. 90-120 psi).

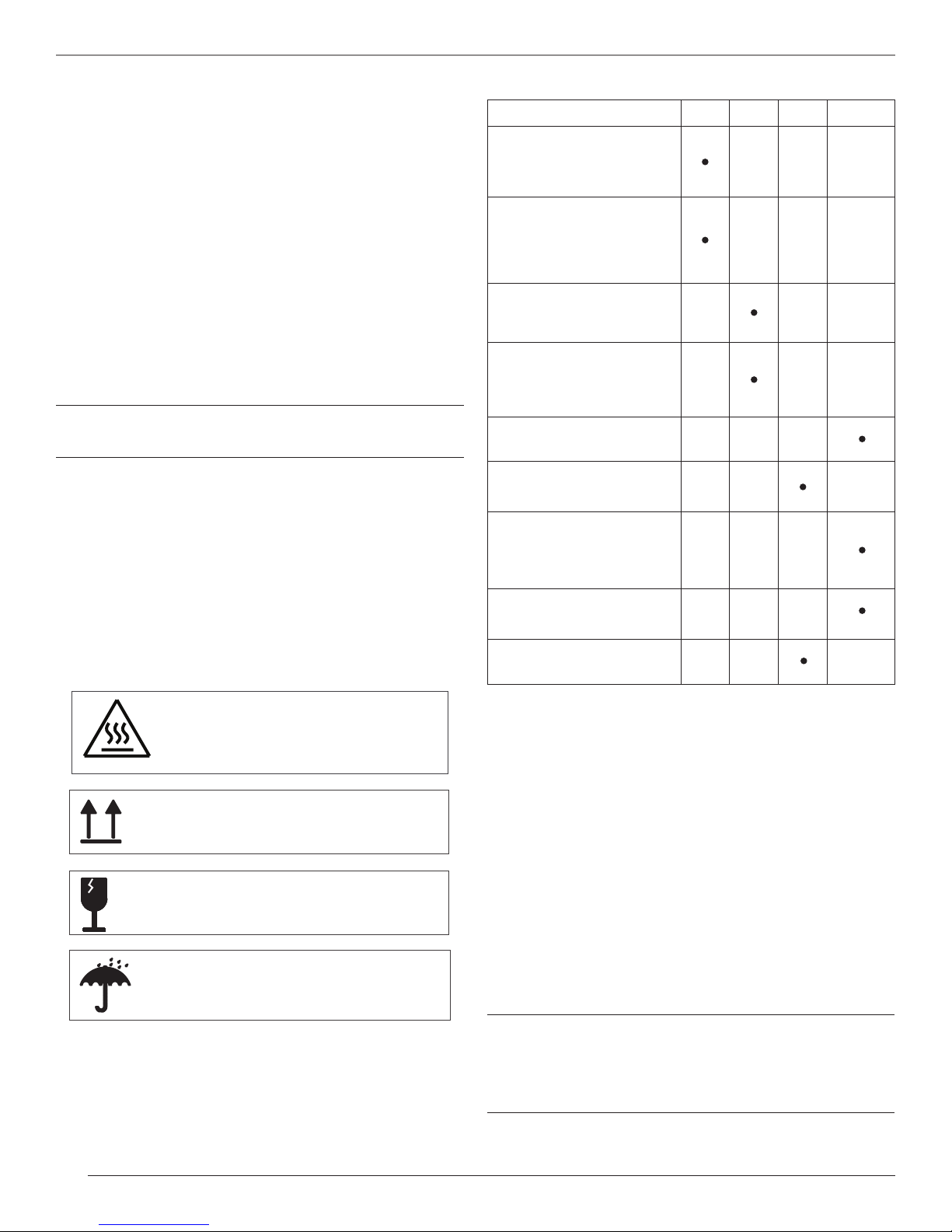

Fault finding and repair

Important!

Switch off and isolate from electrical supply before removing

any parts from the system. Empty air receiver of air before

dismantling parts of system unit’s pressure system.

1. System does not start:

a) No power from mains. Check fuses and plug.

b) Breakage or loose joints in electrical connections.

c) Defective capacitor.

d) The thermal protection has switched off the pump due to overheating.

When cooled the pump will automatically turn on at a suitable

operation temperature. Go through the points in step 5.

e) The system has not been unloaded and there is back pressure. Make

sure that the system is unloaded each time it stops.

f) The pump is locked.

g) Pressure in the air receiver is too high for activation of the pressure

switch. The pressure switch makes circuit only when pressure has

dropped to preset start pressure. Empty receiver.

2. System does not start, makes a buzzing sound followed by a

clicking noise (cannot start against high pressure):

a) Leaky non-return valve. Remove the flexible pressure pipe and clean

to find out whether air leaks from the valve. If so, clean or replace.

3 System works, but pressure does not increase:

a) Intake filter clogged. Replace.

b) Leaks in fittings, tubes or pneumatic equipment. Check with soapy water

or by letting unit stay overnight with disconnected mains. Pressure drop is

not to exceed 1 bar.

c) Cups are worn out. Check and replace if neccessary.

d) Defective valve plate. Contact your JUN-AIR distributor.

e) Burr or failure in non-return valve which is creating a flow restriction.