Page 2

www.juralco.co.nz ph (09) 478 8018

Issue 10-23 v2

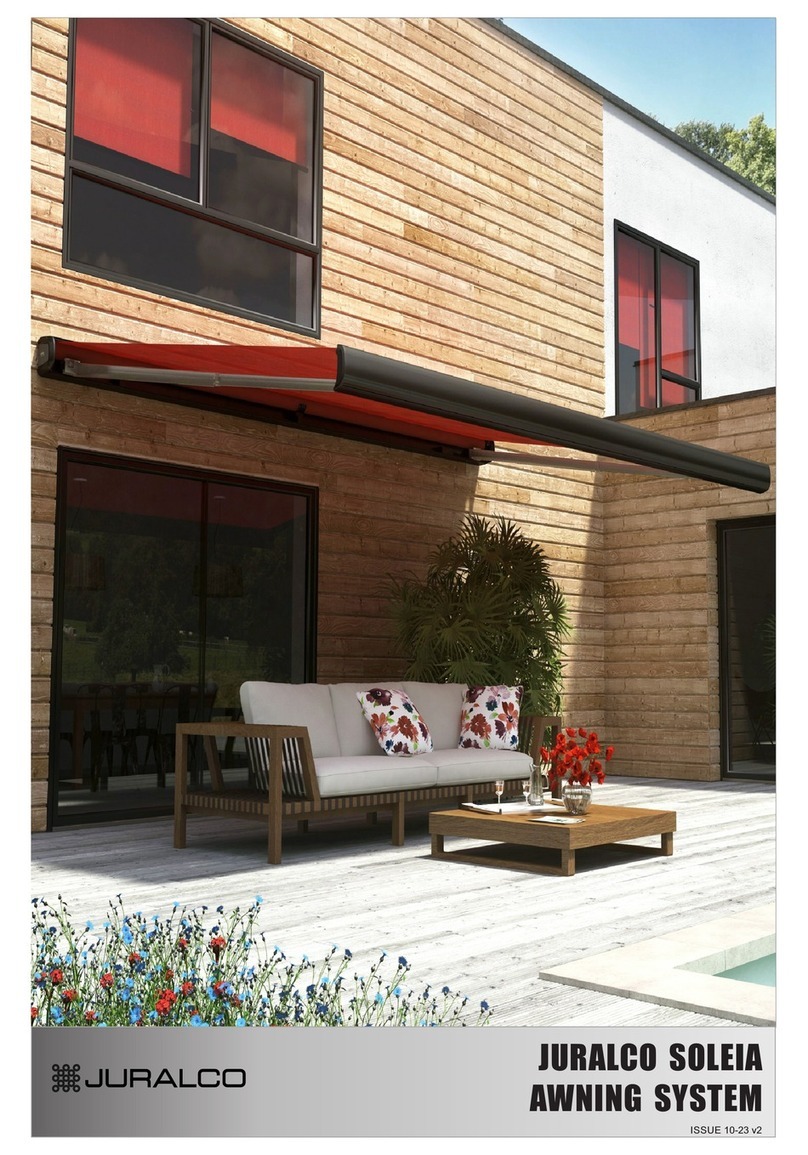

Juralco Felicia Awning System

Juralco Felicia Awning System

Juralco Aluminium Building Products Ltd designs and distributes specialist aluminium

joinery systems through a national network of franchised fabricators and agents.

0

For more than 25 years we have been at the forefront of specialist aluminium door and

window products suitable for New Zealand joinery and building methods. Our

comprehensive product range includes security and insect screens, balustrades and gates,

shutters and awnings, shower screens, wardrobe doors and organisers and internal doors.

0

The Juralco Felicia Awning is a compact, ready-to-install, cantilevered folding twin arm

awning system designed for outside use where protection is needed from sun or light rain.

All the components are made of aluminium alloy, ABS plastic or stainless steel, forming a

highly-resistant, lightweight, rust-proof construction.

General Description

- The Juralco Felicia Awning system is available as a single unit up to 5.9mt wide, with a max 3.5mt awning extension.

- Typical applications include Decks, Bars, Shops, Terraces, or anywhere needing protection from the sun, or light rain.

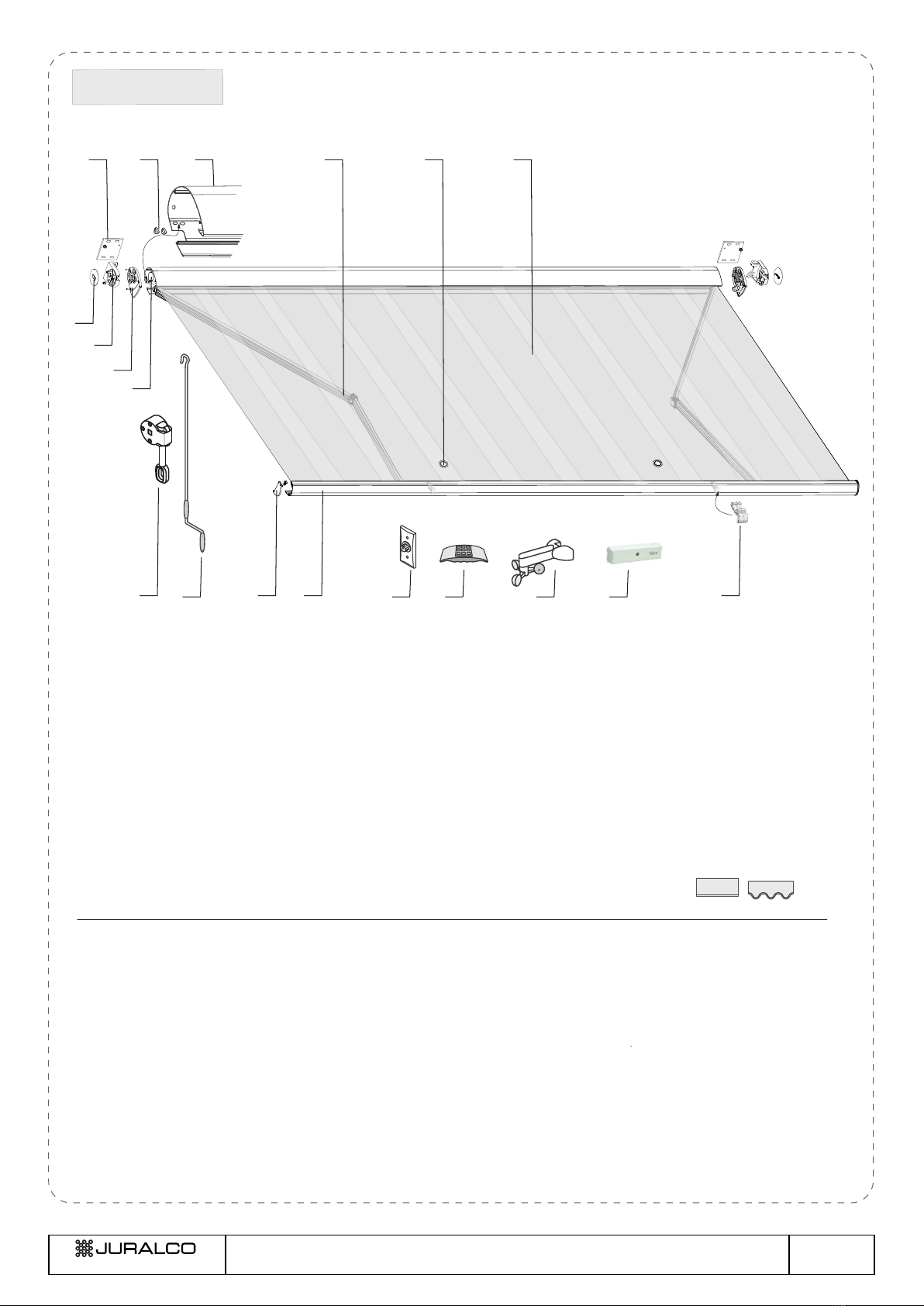

The awning is supplied pre assembled, all necessary brackets, awning roll and two arm units.

- Box - Supplied as a single, enclosed unit complete with mounting brackets. Attachment by end brackets, either wall or ceiling mount.

- Awning fabric - Many styles available, all mildew and UV resistant. A valance to match can be fitted if required.

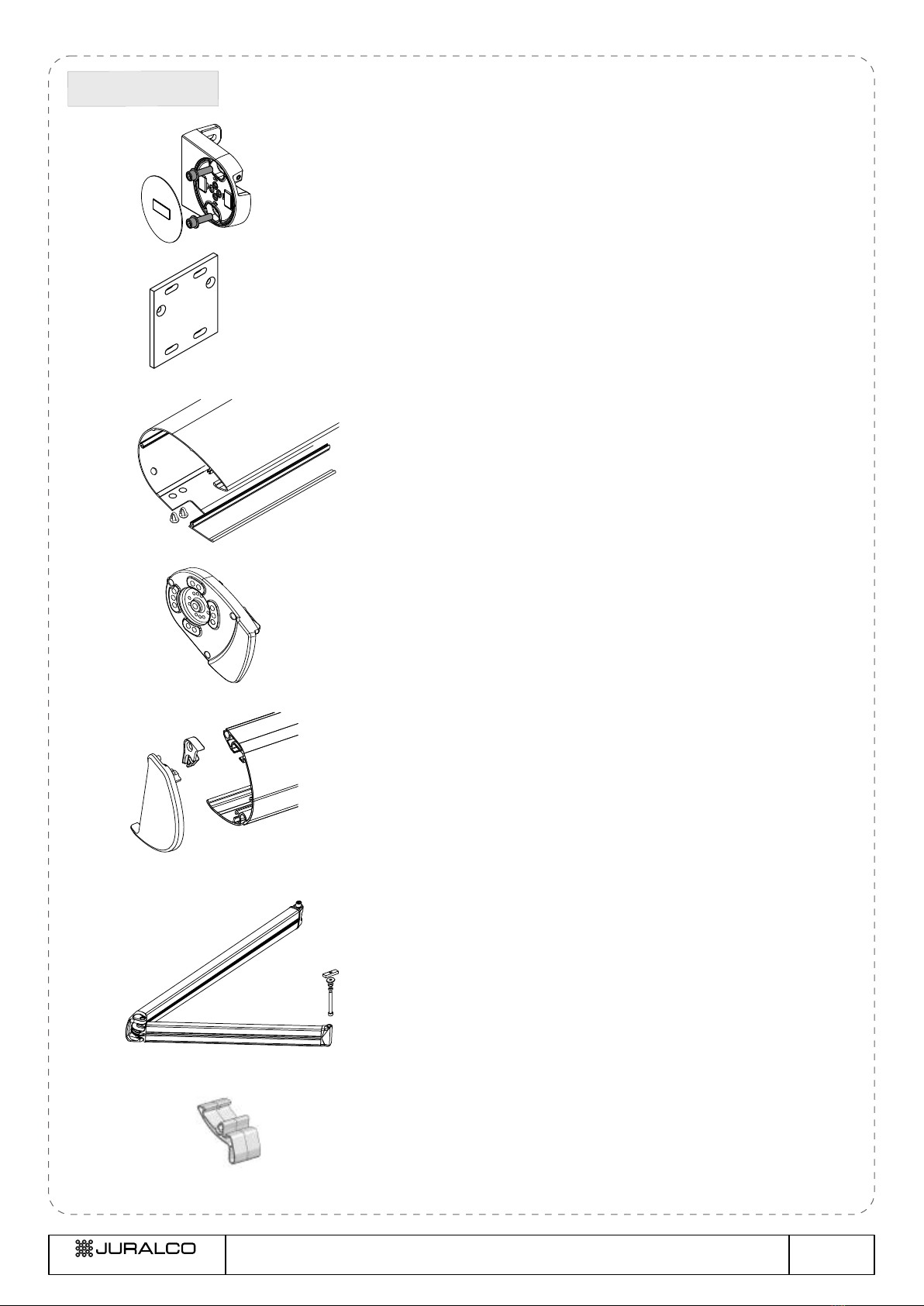

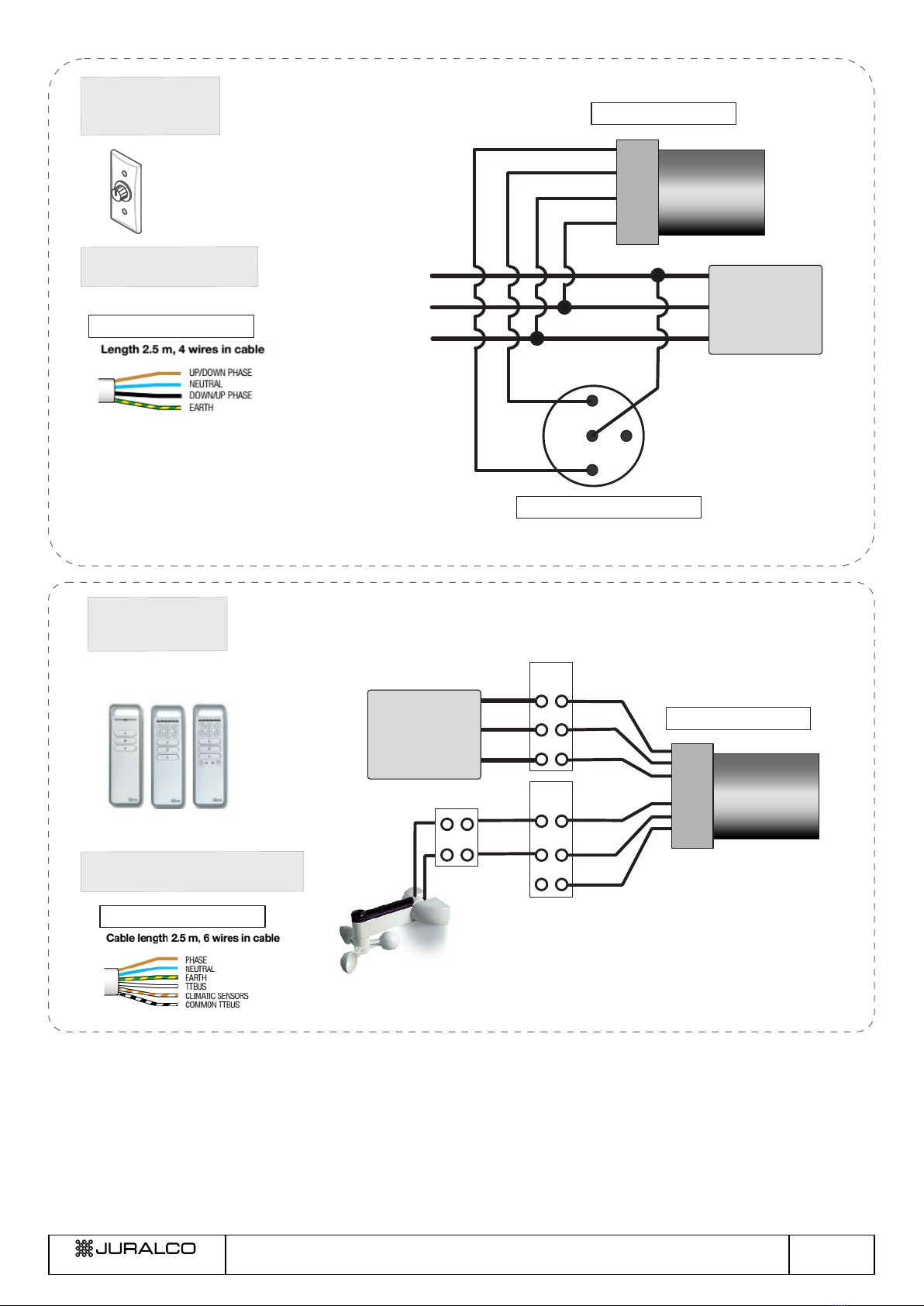

- Drive - Manual - A gearbox fitted to the end of the roller tube assists the operator to raise/lower the curtain.

- Drive - Motorised - An inline tubular motor retracts the awning automatically.

The motor is wired to a 3 position switch in-off-out. Remote wireless controls available. Optional wind sensor.

- Arms - Factory set spring loaded arms evenly tension the fabric cover, and absorb movement in windy conditions.

- Slope - Awning angle adjustable. For Wall mount 0 to 38 degrees down and for Ceiling mount 0 to 58 degrees down.

- Finish - All Aluminium, powder coated colour of your choice. Arms powder coat Silver only.

- Wind - As for all Awnings, care must be taken when installing in Wind prone areas. A Volo wind sensor is strongly recommended.

All pages © Copyright Juralco Aluminium Building Products Ltd, 2023

.

® ® ®

Powdercoat Systems is Also Duralloy and Duratec . The new standard Dulux powder coating system used by Juralco Duralloy Plus .

® ® ®

Juralco Powder coated prices are for Duralloy Plus and Duralloy (same pricing). Duratec prices on application.

The following specs apply to Building Exteriors.

®

- Dulux Duralloy Plus powder coating systems are suitable for properties greater than 10m from high tide level.

Residential and Light commercial buildings, 3 levels max. Warranty 15 yrs

®

- Dulux Duratec powder coating systems are suitable for properties greater than 10m from high tide level

All Residential and Commercial buildings. Warranty 25 yrs.

Important information - Powder Coating systems.

Attachment to structures A PVC Tape or similar material spacer must be used to separate powder coated aluminium items from all concrete

and steel structures. Failure to do so can lead to the chemicals in the structure affecting the powder coating, leading to corrosion.

Swimming Pools The chlorinated water in swimming pools can cause the deterioration of powder coated surfaces, leading to corrosion

of the underlying surface. It is recommended that Powder coated surfaces be 1200mm min from a pool.

Care The Dulux powder coating warranty period is conditional upon the surface being maintained

in accordance with the Dulux ‘Care and Maintenance Instructions’. Download from Dulux or refer to the back page of this manual.