KS-FX202

1-9

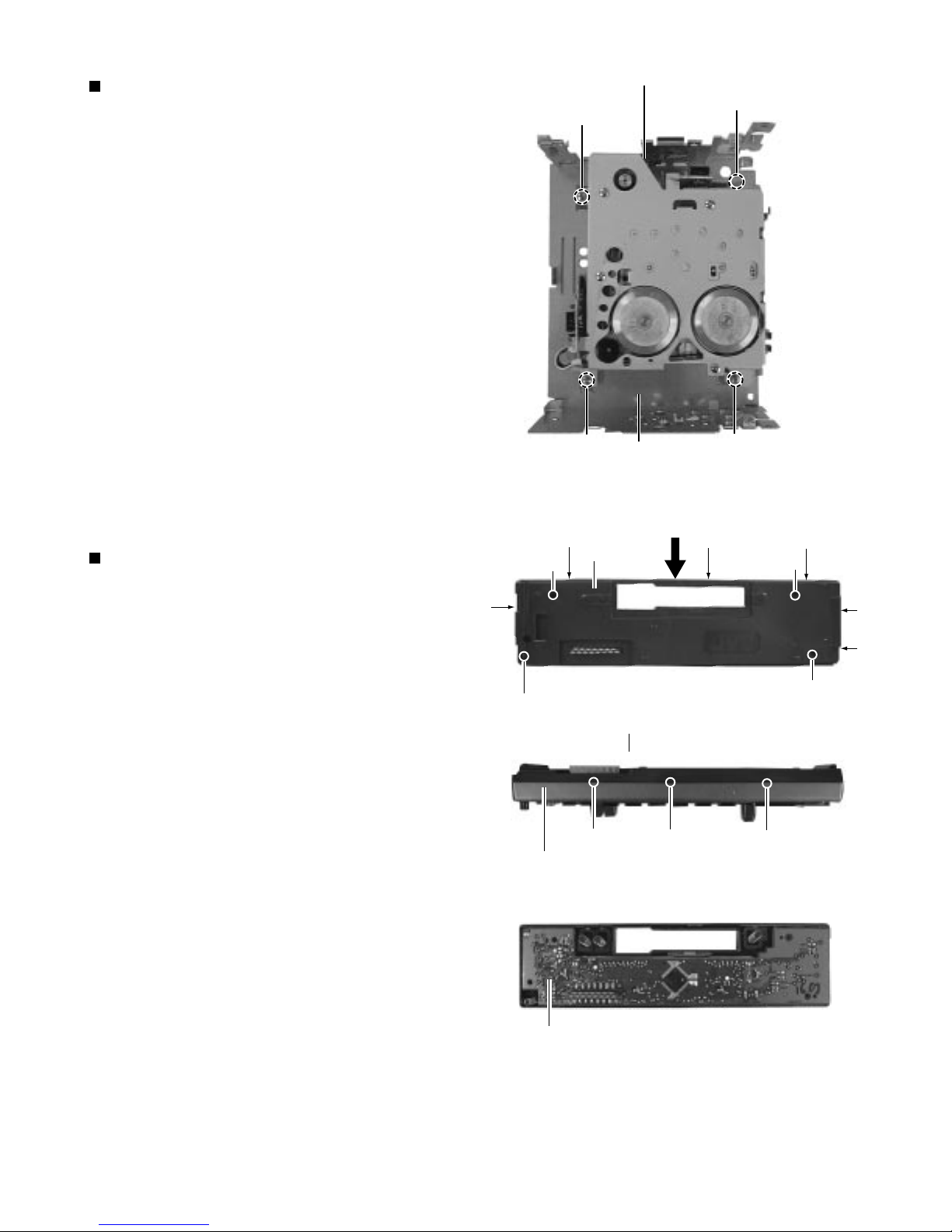

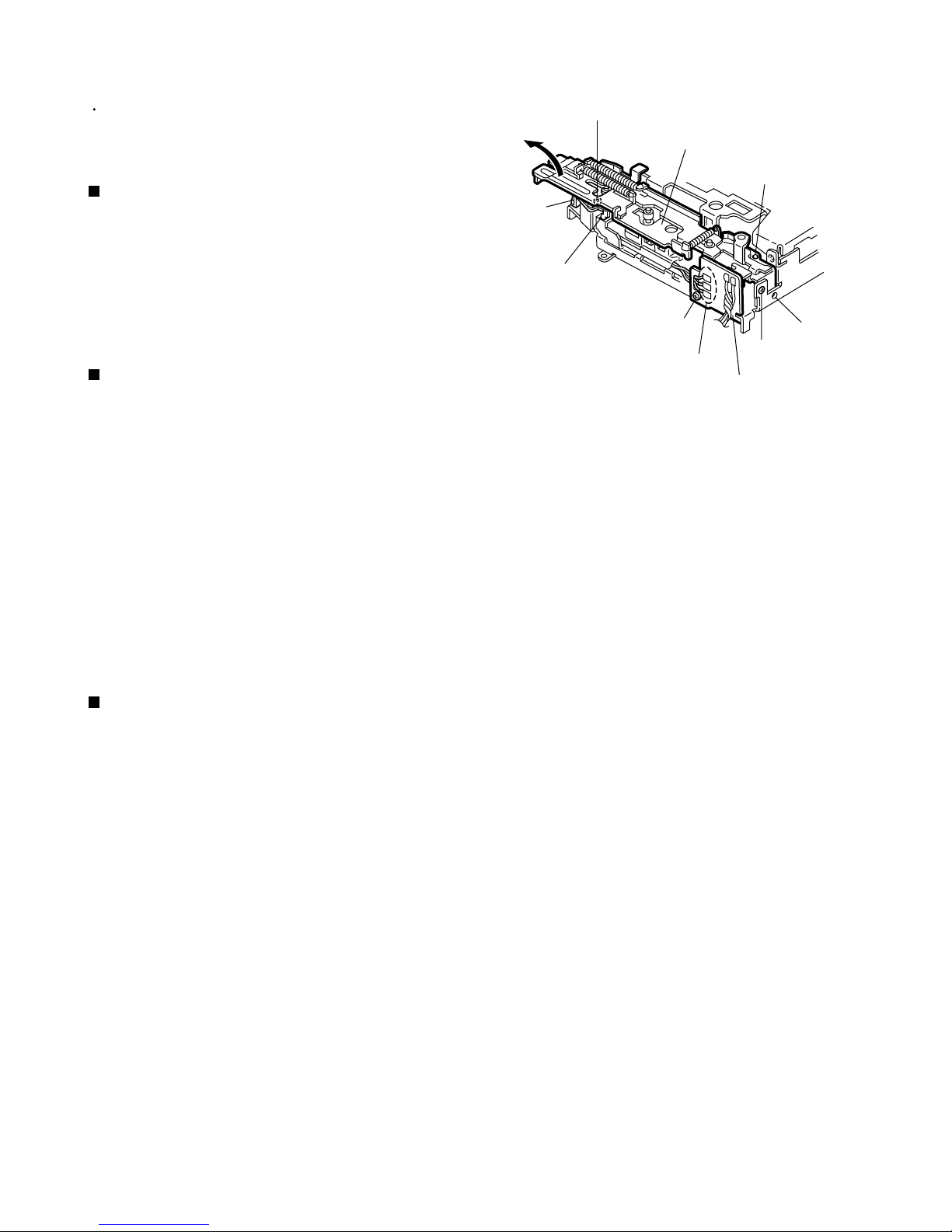

Prior to performing the following procedure, remove

the FF / REW lever assembly.

From the rear of the unit, bend the two tabs f

outwards and disengage the two joints gin the

direction of the arrow.

Push the eject lever and remove the cassette holder

from the playback head. Disengage the two joints h

of the cassette hanger / cassette holder and the eject

lever in the direction of the arrow.

Lift the cassette hanger / cassette holder and disengage

the joint iof the return link and the eject lever.

1.

2.

3.

Removing the cassette hanger / cassette

holder (See Fig.3)

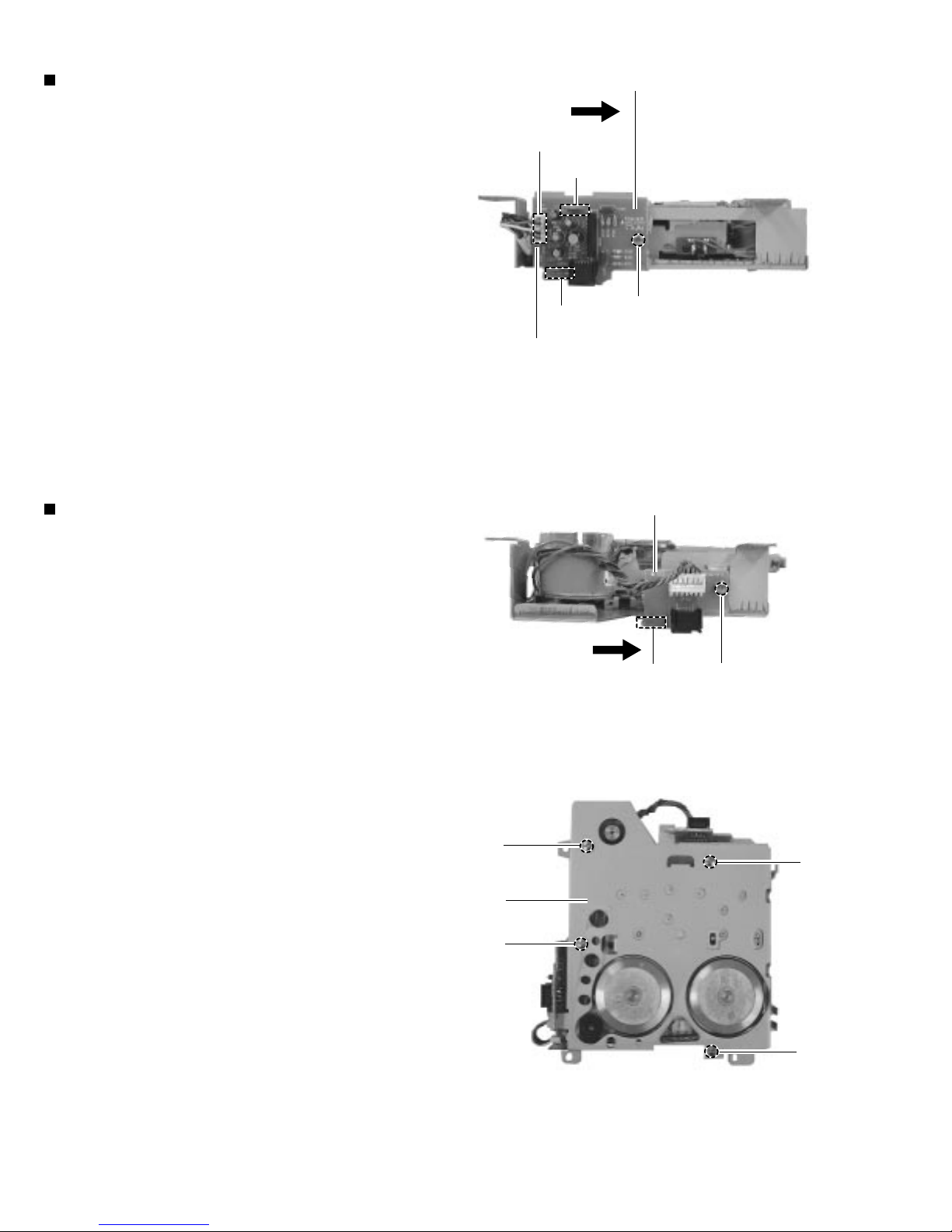

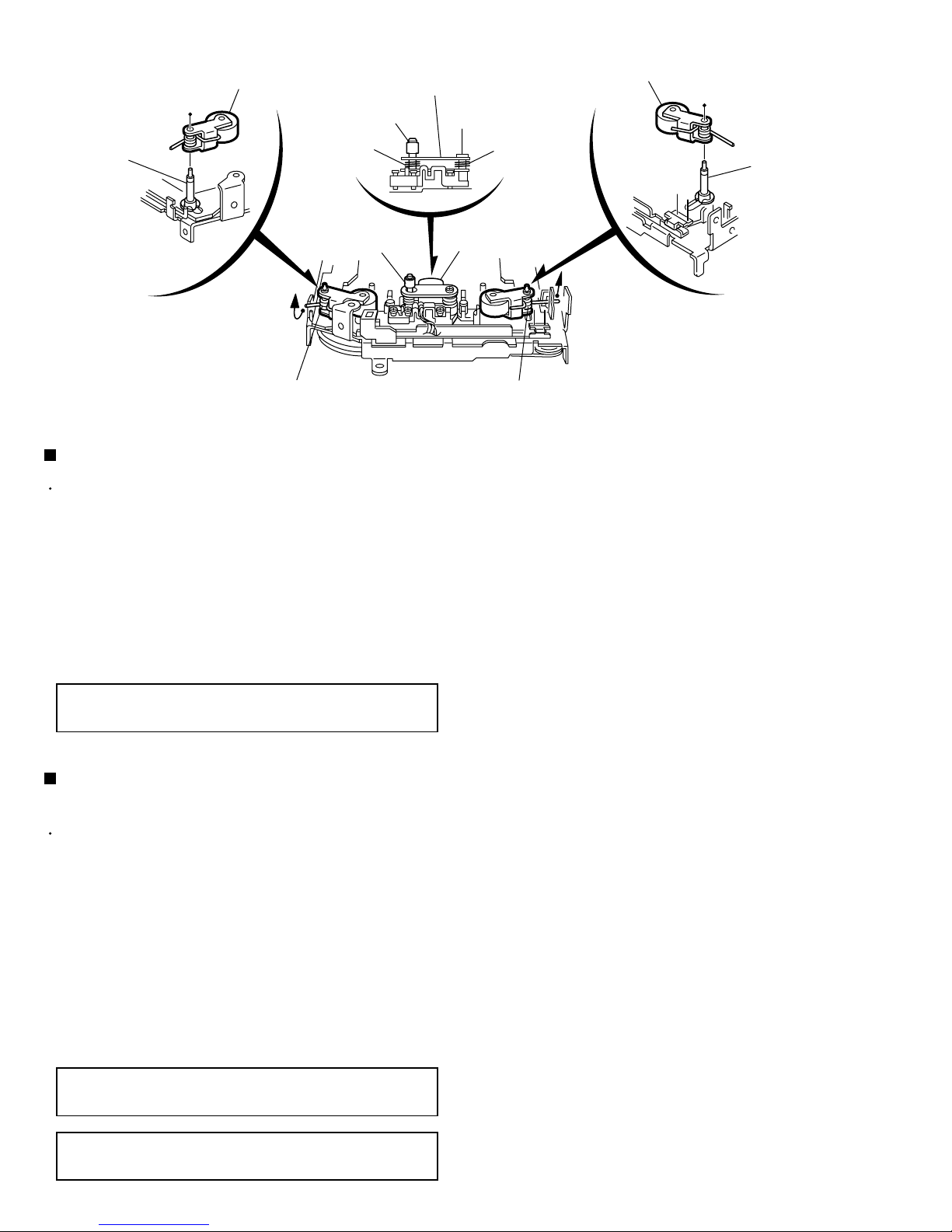

Unsolder the two wires jon the motor assembly.

1.

Turn over the cassette mechanism assembly and

remove the main belt and the sub-belt from the

motor pulley.

2.

Remove the two screws Gattaching the motor

assembly.

3.

Removing the motor assembly

(See Fig.5)

To replace the sub-belt, remove the

main belt and the sub-belt from the

motor pulley. Then remove the three

screws Eand one screw F. Replace

with a new sub-belt while lifting the reel

base assembly slightly.

ATTENTION:

Prior to performing the following procedure, remove

the FF / REW lever assembly and the cassette

hanger / cassette holder.

Remove the C washer and pull out reel disc assembly.

1.

Removing the reel disc assembly

(See Fig.4)

Replace with a new C washer when

reattaching.

ATTENTION:

The main belt can now be removed.

ATTENTION:

Cassette holder

Cassette hanger

Return link

Joint i

Eject lever

Joint h

Joint h

Joint g

Joint g Tab f

Tab f

Reel disc assembly

Flywheel (BF)

Flywheel (BR)

E

E

E

F

G

G

Main-belt

Reel base assembly

Sub-belt

Motor assembly

Motor pulley

Soldering j

Fig.3

Fig.4

Fig.5

C washer

C washer

Chassis