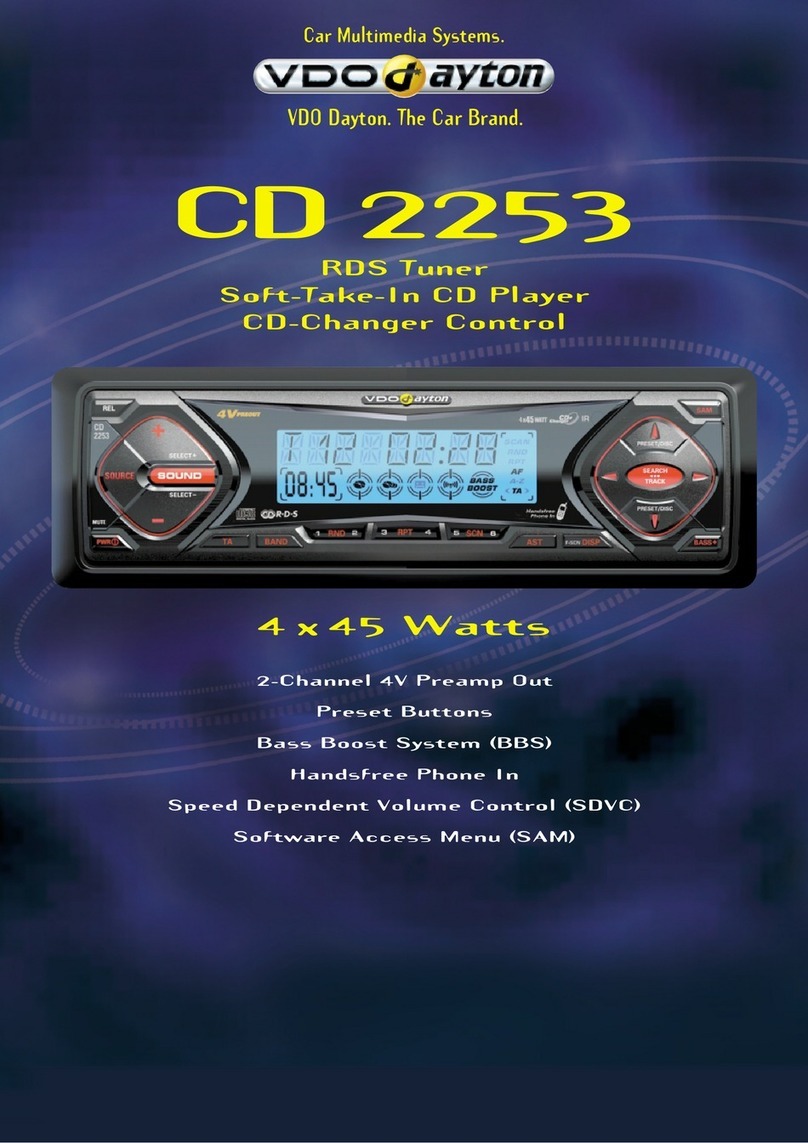

KS-FX925R

1-6

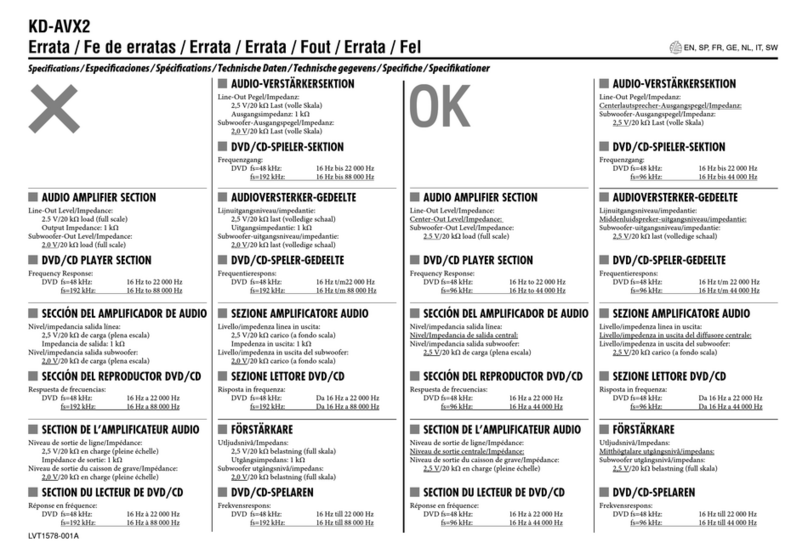

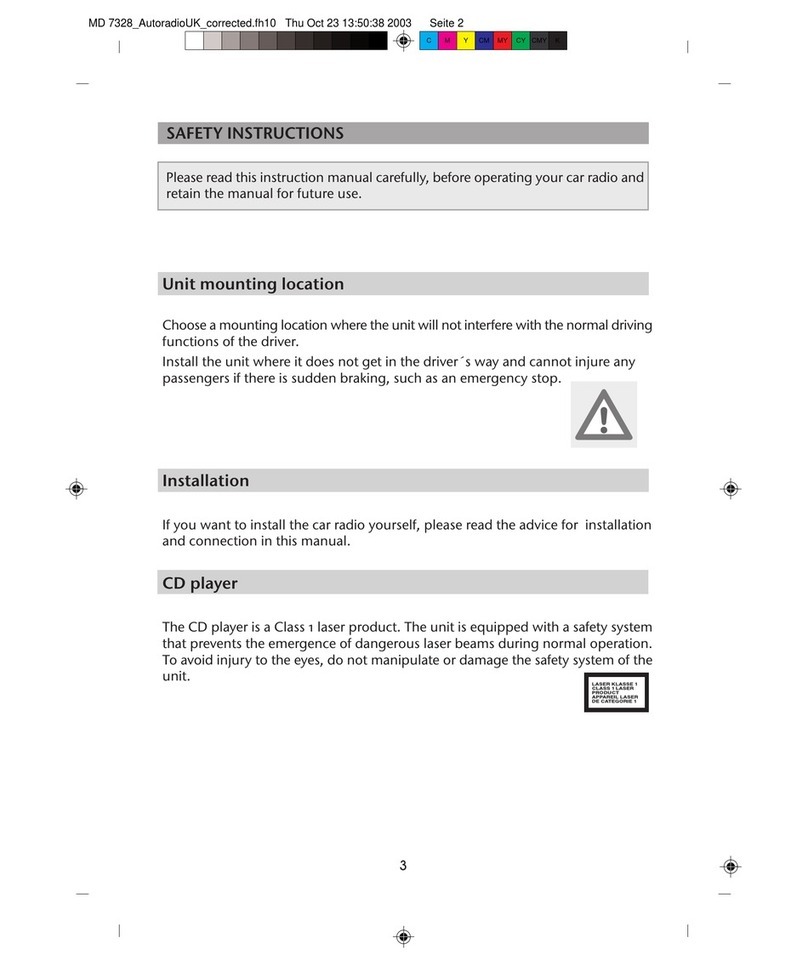

Remove the screw Aattaching the reinforce bracket

on the bottom of the body.

To release joint a, turn and detach the reinforce

bracket from the side bracket assembly as shown in

Fig.2

1.

2.

Removing the reinforce bracket

(See Fig.1 and 2)

Turn the mode gear to set to RVS play or

subsequent mode.

Remove the cassette guide from the main chassis

while releasing each two joint tabs bin the direction

of the arrow.

1.

2.

Removing the cassette guide (See Fig.3)

Remove the screw Bon the upper side. Unsolder

the wires on the under side of the head board, if

necessary.

1.

Removing the head board (See Fig.4)

Prior to performing the following

procedures, turn the mode gear on the

bottom of the body until the respective part

comes to the EJECT position (Refer to

Fig.1).

REFERENCE:

When reassembling, twist the wires by

turning the head board twice remarked c

and pass through the notch das shown

in Fig.4.

REFERENCE:

Head board

Fig.1

Fig.2

Fig.4Fig.3

Mode gear

Reinforce bracket

Reinforce bracket

Joint a

Cassette guide

Tab b

Tab b

B

Head board

notch d

c

Soldering

A

<Cassette mechanism section>