Contents

General notes

Read these original operating instruc-

tions and the enclosed safety instruc-

tions before using the device for the first

time. Proceed accordingly.

Keep both books for future reference or for future own-

ers.

Intended use

Use this high-pressure cleaner only for the following

types of work:

ƔThe high-pressure jet is intended exclusively for

cleaning, e.g. machines, vehicles, structures, tools,

facades, terraces and garden equipment.

We recommend using a dirt blaster as a special acces-

sory for stubborn soiling.

The device is suitable for operation in altitudes of up to

500 m. For operation in higher altitudes the engine must

be adapted by the KÄRCHER Customer Service.

DANGER

Operating the device at gas stations or other dan-

gerous areas

Risk of injury!

Follow the respective safety regulations.

Note

Please do not let waste water contaminated with miner-

al oil reach soil, water or the sewage system. Only clean

the engine and the engine bottom in a suitable site with

an oil trap.

Water supply limit values

ATTENTION

Dirty water

Premature wear and tear or deposits in the device

Supply the device using only clean water, or recycled

water that does not exceed the specified limit values.

The following limit values apply to the water supply:

ƔpH value: 6.5-9.5

ƔElectrical conductivity: Conductivity of fresh water

+ 1200 µS/cm, maximum conductivity 2000 µS/cm

ƔSettleable particles (sample volume 1 l, settling time

30 minutes): < 0.5 mg/l

ƔFilterable particles: < 50 mg/l, no abrasive sub-

stances

ƔHydrocarbons: < 20 mg/l

ƔChloride: < 300 mg/l

ƔSulphate: < 240 mg/l

ƔCalcium: < 200 mg/l

ƔTotal hardness: < 28°dH, < 50° TH, < 500 ppm

(&D&RPJO)

ƔIron: < 0.5 mg/l

ƔManganese: < 0.05 mg/l

ƔCopper: < 2 mg/l

ƔActive chloride: < 0.3 mg/l

ƔFree of unpleasant odours

Environmental protection

The packing materials can be recycled. Please

dispose of packaging in accordance with the en-

vironmental regulations.

Electrical and electronic appliances contain valu-

able, recyclable materials and often components

such as batteries, rechargeable batteries or oil,

which - if handled or disposed of incorrectly - can

pose a potential threat to human health and the environ-

ment. However, these components are required for the

correct operation of the appliance. Appliances marked

by this symbol are not allowed to be disposed of togeth-

er with the household rubbish.

Notes on the content materials (REACH)

Current information on content materials can be found

at: www.kaercher.com/REACH

Accessories and spare parts

Only use original accessories and original spare parts.

They ensure that the appliance will run fault-free and

safely.

Information on accessories and spare parts can be

found at www.kaercher.com.

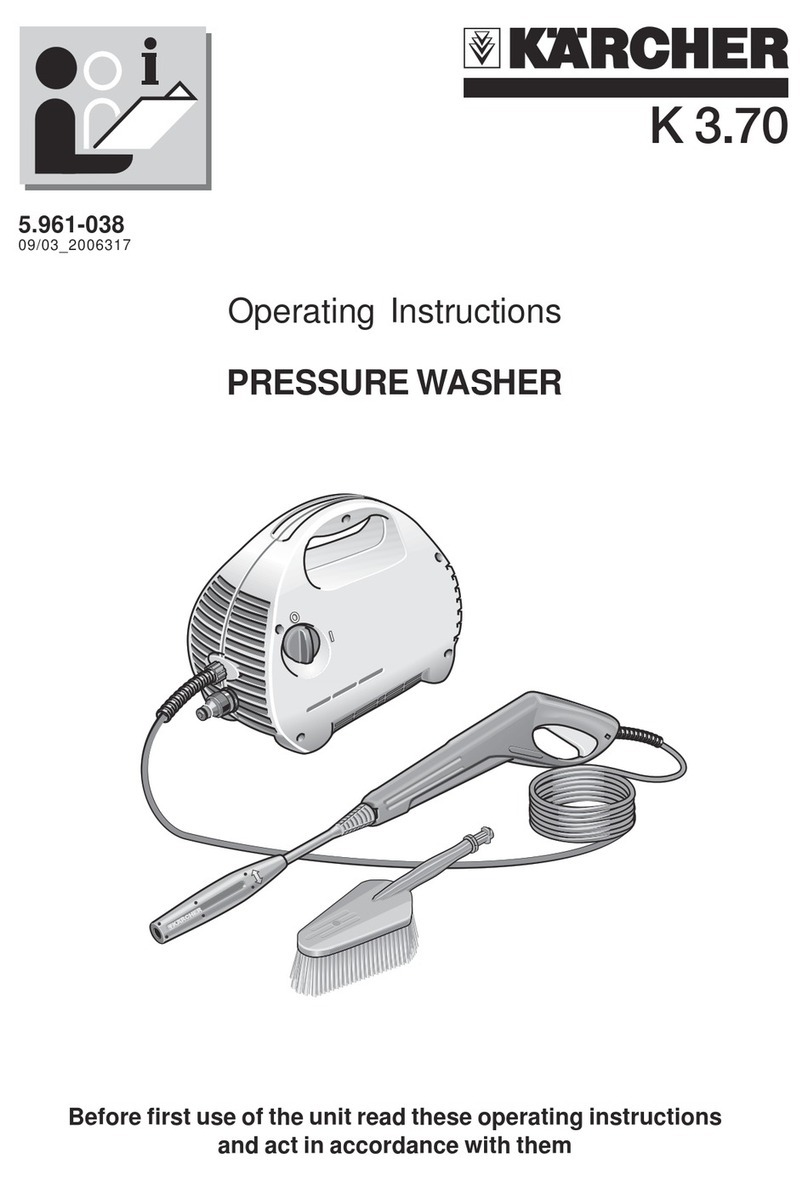

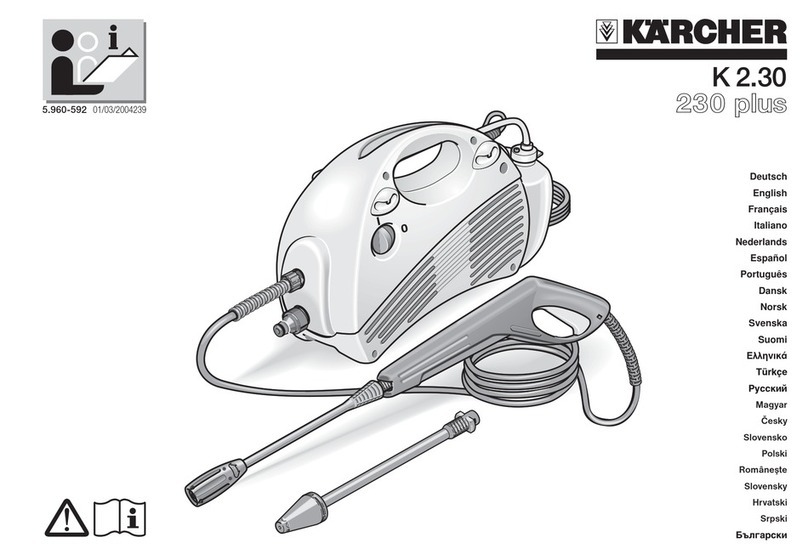

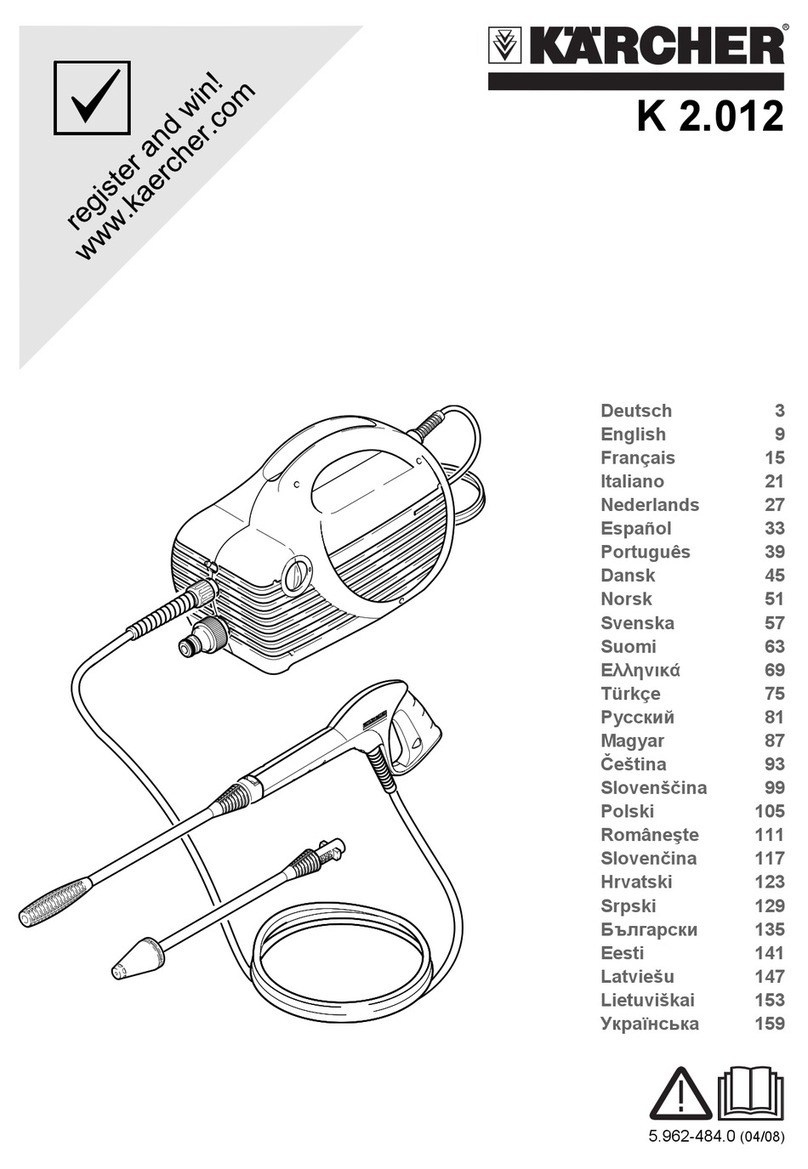

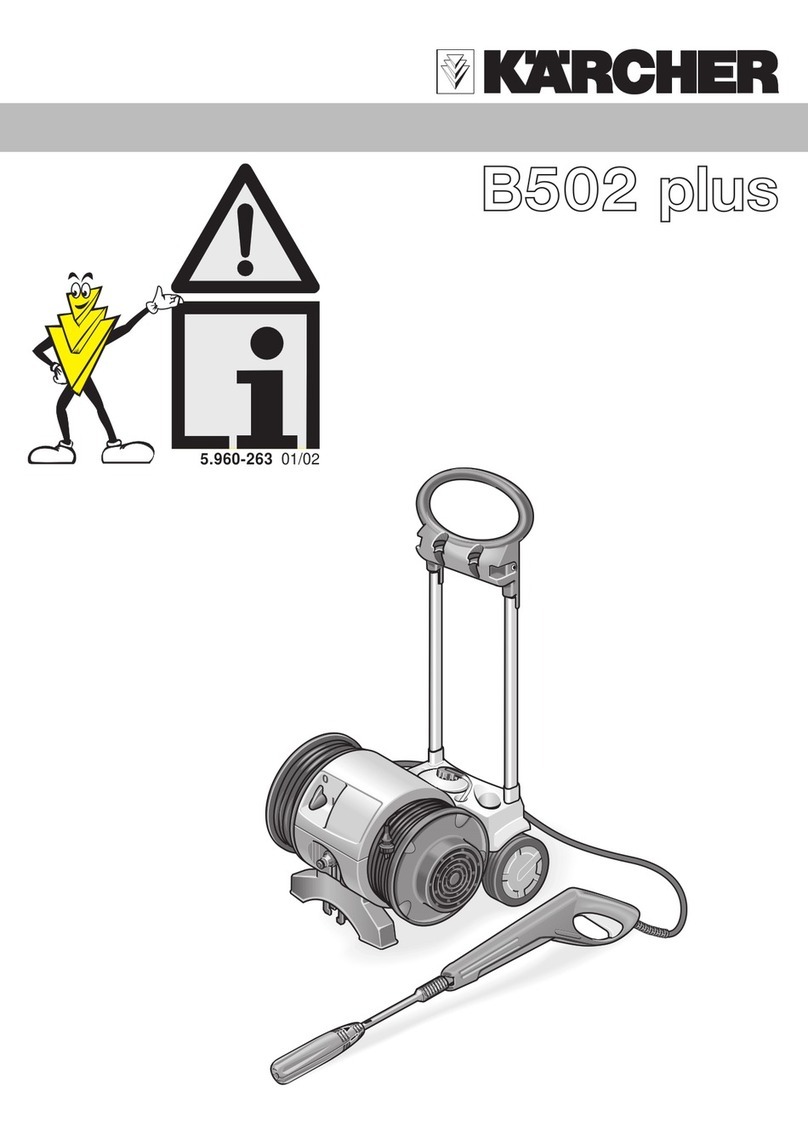

Scope of delivery

Check the contents for completeness when unpacking.

If any accessories are missing or in the event of any

shipping damage, please notify your dealer.

Symbols on the device

General notes......................................................

Intended use........................................................

Environmental protection.....................................

Accessories and spare parts ...............................

Scope of delivery .................................................

Symbols on the device ........................................

Safety instructions ...............................................

Safety devices .....................................................

Device description ...............................................

Colour coding ......................................................

Initial start-up.......................................................

Operation.............................................................

Transportation .....................................................

Storage................................................................

Care and service .................................................

Troubleshooting guide .........................................

Warranty ..............................................................

Safety instructions High-pressure cleaner...........

Technical data ..................................................... 1

Risk of burns from hot surfaces.

Do not aim the high-pressure jet may at per-

sons, animals, live electrical equipment or

the device itself.

Protect the device against frost.

According to applicable regulations, the de-

vice must never be used with the drinking

water network without a system separator.

Ensure that the connection to your house

water system, with which the high-pressure

cleaner is operated, is equipped with a sys-

tem separator according to EN 12729 type

BA. Water that has flowed through a system

separator is classified as undrinkable. Al-

ways connect the system separator to the

water inlet and never directly to the device.

Health risk from poisonous exhaust gases.

Never inhale the exhaust gases.