Operation Manual MUB-1

KAKA Industrial®

— 1 —

Unpacking

The UNIVERSAL BENDER is shipped from

the manufacturer in a carefully packed Carton

box. Thoroughly inspect the product upon

opening the package.

After unpacking the unit, carefully inspect for

any damage that may have occurred during

transit. Check for loose, missing, or damaged

parts. Shipping damage claims must be led

with the carrier and are the responsibility of

the user.

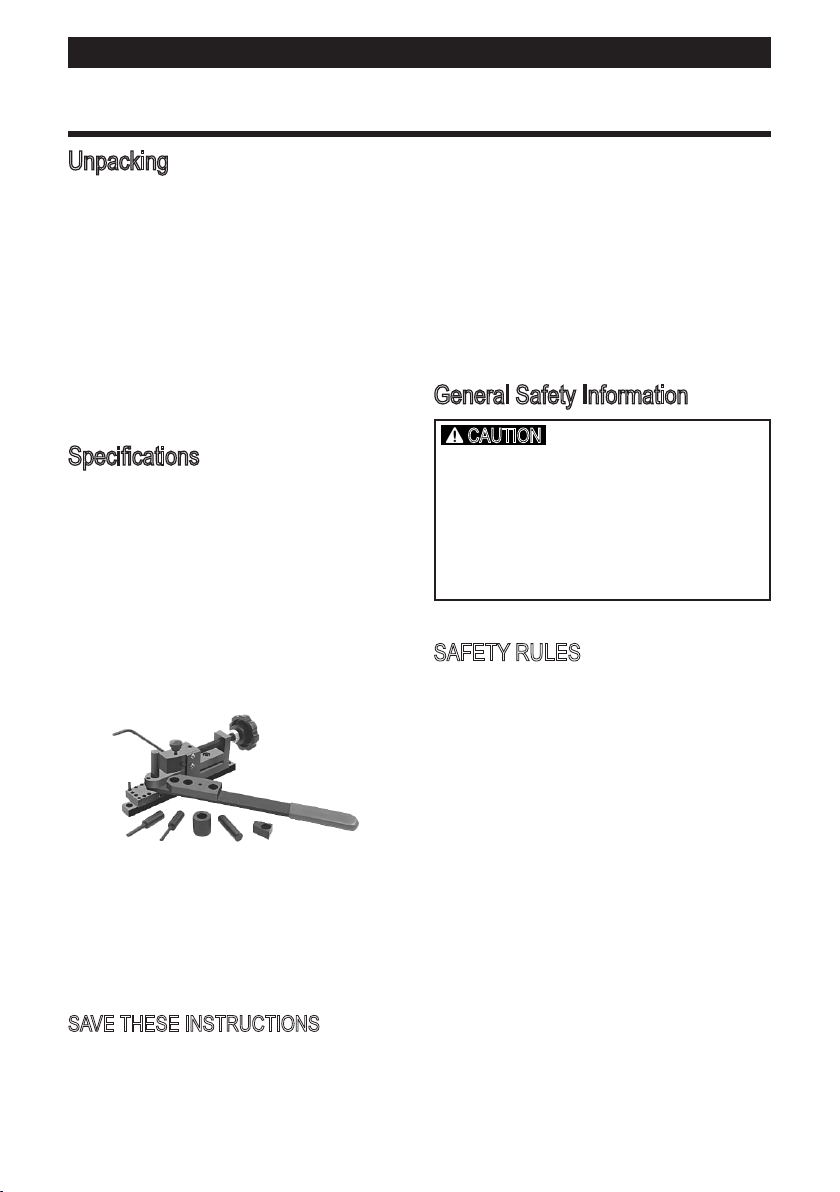

Specications

The KAKA UNIVERSAL BENDER is the

perfect addition to any fabricator’s work bench.

It is precision designed and manufactured to

allow for quick and easy wire, flat metal and

tubing into clamps, handle brackets, hooks,

coils, and more. Make sharp angle bends in

wire and rod. Includes circle pins for 3/16",

1/4",1/2" dia, cirle 1" diacircle die, form pin

follower, sharp angle die, gauge and handle

Stock No. ............................................173207

Model....................................................MUB-1

Packing size.............13"x4"x4" (32X10X10 cm)

N.W./G.W..........................6.2/6.6 lbs (2.8/3 kg)

SAVE THESE INSTRUCTIONS

Thank you for purchasing our MUB-1

UNIVERSAL BENDER machine. Before

attempting to operate your new tool please

read these instructions thoroughly. You

will need these instructions for the safety

warnings, precautions, assembly, operation,

maintenance procedures, parts list and

diagrams. Keep your invoice number with

these instructions. Write the invoice number

on the inside of front cover. Keep the

instructions and invoice in a safe, dry place for

future reference.

General Safety Information

CAUTION

Always follow proper operating procedures

as defined in this manual even if you are

familiar with use of this or similar tools.

Remember that being careless for even a

fraction of a second can result in severe

personal injury.

SAFETY RULES

1. Wear proper apparel. Do not wear loose

clothing, gloves, neckties, rings, bracelets or

other jewelry which may get caught in moving

parts of machine.

2. Wear protective hair covering to contain

long hair.

3. Wear safety shoes with non-slip soles.

4. Wear safety glasses complying with United

States ANSI Z87.1.

Everyday glasses have only impact resistant

lenses. They are NOT safety glasses.

5. Be alert and think clearly. Never operate

tools when tired, intoxicated or when taking

medications that cause drowsiness.

6. Keep work area clean. Cluttered work areas

invite accidents.

7. Work area should be properly lit.

8. Keep visitors at a safe distance from work area.

9. Keep children out of workplace. Make