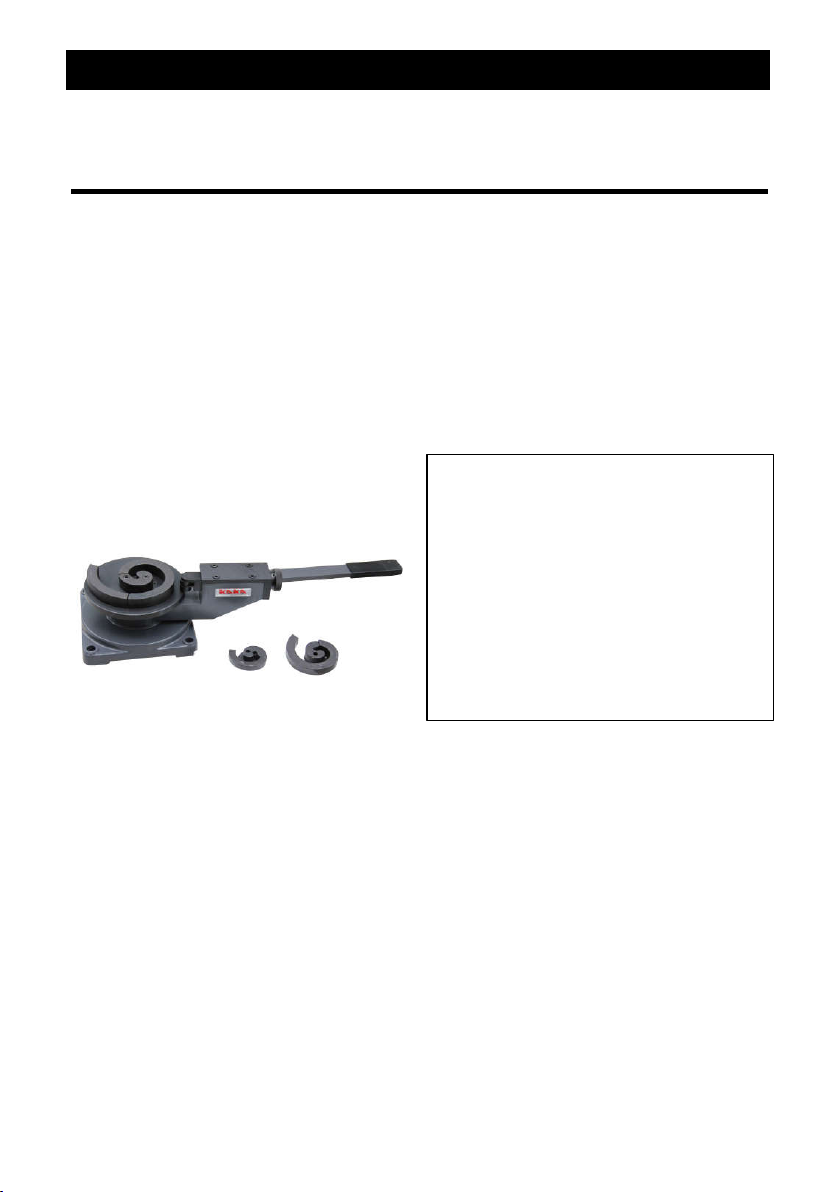

Operation Manual SBG-30

Model SBG-30

- 2 -

READ ALL INSTRUCTIONS

BEFORE USING THIS TOOL!

1.KEEP WORK AREA CLEAN. Cluttered

areas invite injuries.

2.OBSERVE WORK AREA CONDITIONS.

Do not use tools in damp, wet, or poorly

in locations. Don’t expose to rain. Keep

work areas well fit. Do not use electrically

powered equipment in the presence of

flammable gases or liquids.

3.KEEP CHILDREN AWAY. Children must

never be allowed in the work area. Don’t

let them handle the benders.

4.STORE IDLE EQUIPMENT. When not

in use, tools must be locked up in a dry

location without rust. Always lock up tools

and keep out or reach of children.

5.DO NOT FORCE THE BENDER. It will

do the job better and more safety at the

rate for which it was intended. Do not use

inappropriate attachments in an attempt

to exceed the tool’s capacities.

6.USE EYE, EAR AND BREATHING

PROTECTION. Always wear ANSI

approved impact safety goggles.

7.DO NOT OVERREACH. Keep proper

footing and balance at all times.

8.MAINTAIN TOOLS WITH CARE. Keep

tools clean for better and safer

performance. Keep handle dry, clean, and

free from oil and grease.

9.STAY ALERT. Watch what you are dong.

Do not operate any machinery when you

are tired.

10.CHECK FOR DAMAGED PARTS.

Before using any tool, any part that

appears damaged should be carefully

checked to determine that it would

operate properly and perform its intended

function. Check for alignment and binding

of moving parts, any broken parts or

mounting fixtures, and any other

condition that may affect proper operation.

Any part that is damaged should be

properly repaired or replaced by an