10

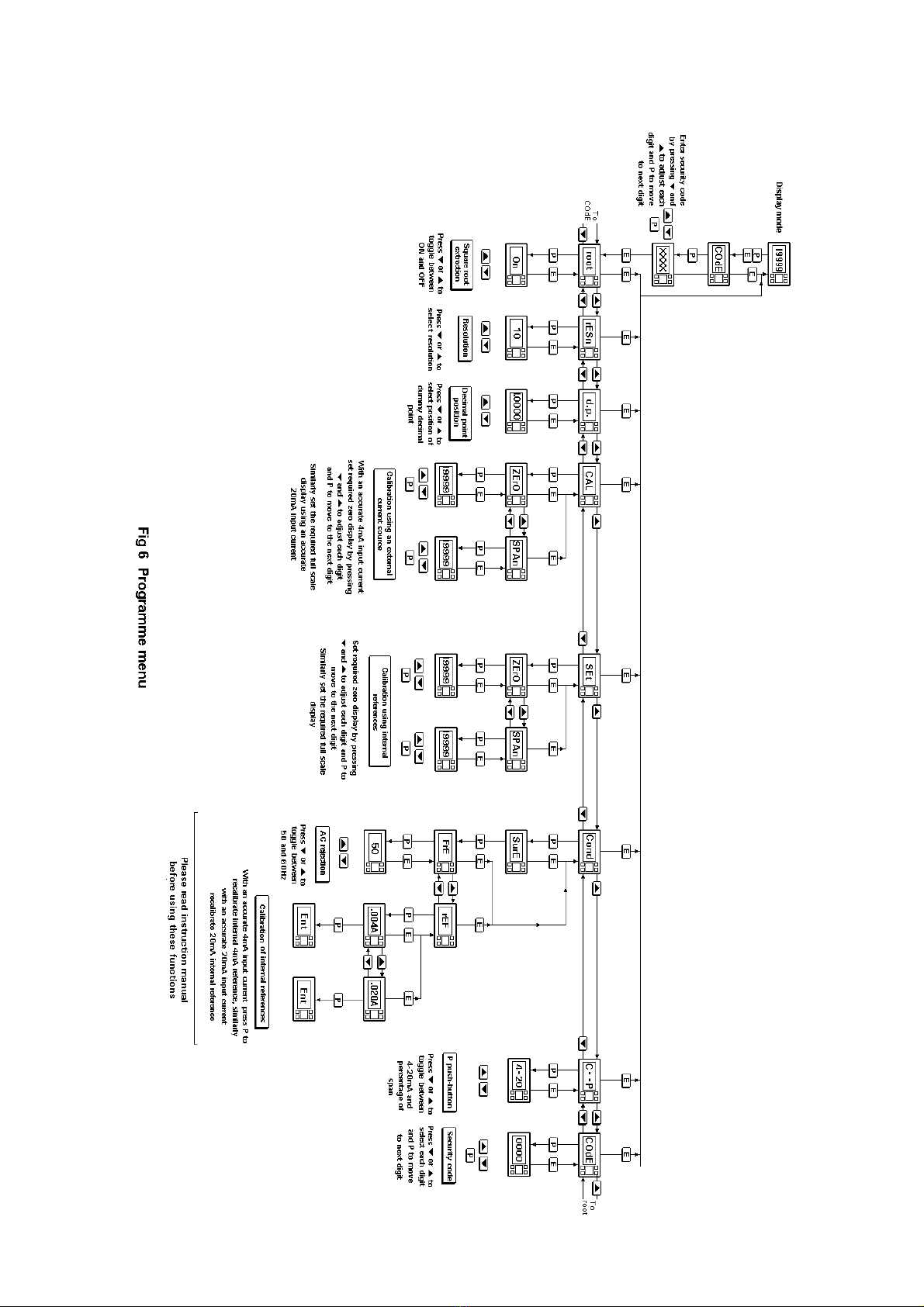

5.7 Conditioning sub-menu: Cond

This sub-menu allows the mains (line) frequency at

which the indicator has maximum ac rejection to be

selected and the two internal references to be

calibrated. These functions are contained in a sub-

menu to minimise the possibility of inadvertent

adjustment. To gain access to the sub-menu select

'Cond' from the main menu and press P. The

indicator will display 'SurE' to warn that changing

the parameters in the sub-menu will change the

indicator display. Pressing Pagain will give access

to the sub-menu, or pressing Ewill return the

indicator to the main menu.

5.7.1 AC rejection: FrE

Caution

If the mains filter frequency is

changed, the indicator display and

internal references (if used) must

be recalibrated.

To provide maximum low frequency rejection the

internal digital filter may be set to operate at 50 or

60Hz to correspond with the local mains (line)

frequency. To change the frequency select 'FrE'

from the Cond sub-menu and press Pwhich will

reveal the current setting. The setting can be

changed by pressing the Up or Down buttons

followed by the Ebutton to return to the sub-menu.

5.7.2 Calibration of internal references: rEF

The indicator contains two references representing

4 and 20mA. These references are used in the

'SEt' function which enables the indicator display to

be calibrated without an external current calibrator.

They are also used in the 'C--P' function when the

Ppush-button is programmed to display the input

current in the display mode. If neither of these

functions is to be used, it is not necessary to

calibrate the internal references.

To calibrate the references select 'rEF' from the

sub-menu and press Pwhich will result in a

'0.004A' prompt being displayed. Adjust the

external current calibrator to 4.000mA and again

press P. The indicator will display 'Ent' when the

4mA reference has been updated and will then

return to the '.004A' prompt.

To re-calibrate the 20mA internal reference, press

the Up button which will cause the indicator to

display '.020A'. Adjust the external current

calibrator to 20.000mA and again press P. The

indicator will display 'Ent' when the 20mA

reference has been updated and will then return to

the '.020A' prompt. Two operations of the Ebutton

will return the indicator to the main menu.

The accuracy of the internal references, and hence

the display accuracy, will depend upon the

accuracy of the external current source. With a

maximum span of 19999 the indicators have a

display resolution of 0.8µA, we therefore

recommend that the accuracy of the external

current source used for calibration is greater than

0.4µA.

5.8 Function of the P push-button: C - - P

This parameter defines the function of the P

pushbutton when the indicator is in the display

mode. While the button is operated the indicator

will display the input current in milliamps, or the

input current as a percentage of the span.

To check or change the parameter select 'C - -P'

from the main menu and press Pto reveal the

current setting. Pressing the Up or Down button

will toggle the setting between '4-20' the current

display and 'PC' the percentage display. When set

as required press Eto return to the main menu.

Accuracy of the current display depends upon the

accuracy of the internal references which should

be periodically calibrated - see section 5.7.2

5.9 Security code: COdE

The calibration and conditioning of the instrument

may be protected by a four digit security code

which must be entered before access to the

programme menu is granted. New instruments are

programmed with the default security code 0000

which allows unrestricted access to all

programming functions.

To enter a new security code select 'COdE' from

the menu and press Pwhich will cause the

indicator to display the current security code. Each

digit of the code can be changed using the Up or

Down push-button, and the Pbutton to move to the

next digit. When the required code has been

entered press Eto return to the main menu. The

revised security code will be activated when the

indicator is returned to the operating mode.

If the security code is lost, access to the

programmable functions can be obtained by

moving the internal security link to the override

position. The original security code can then be

viewed by selecting 'CodE' from the main menu

and pressing P.