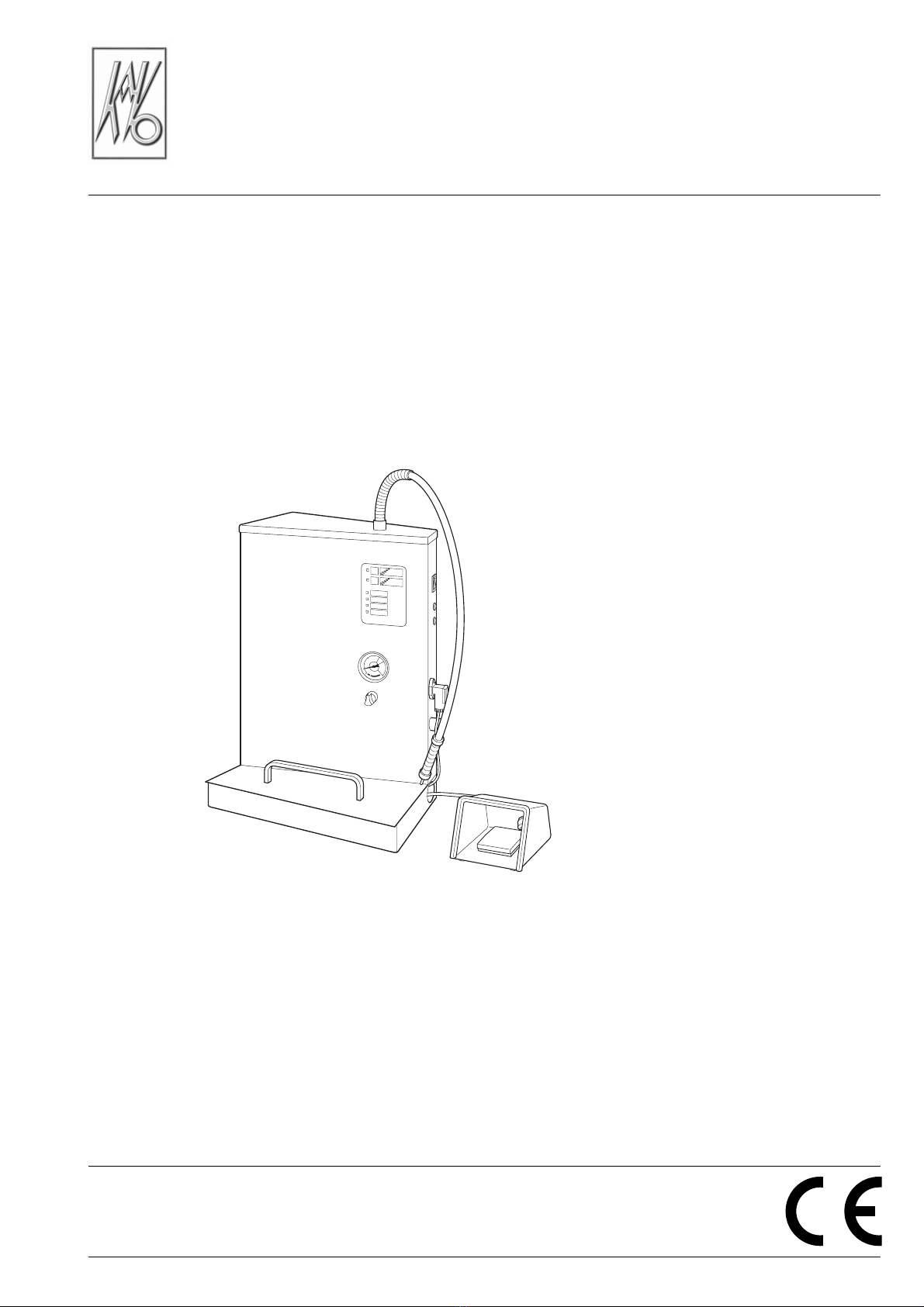

6EWL 5839

A 8.3 Repairs

Servi e or repairs of the unit must be arried out only by trained te hni al personnel.

Modifi ations by others, and use of unauthorized parts, invalidates the Produ t Liability.

Use only original spare parts.

A 9 Technical data

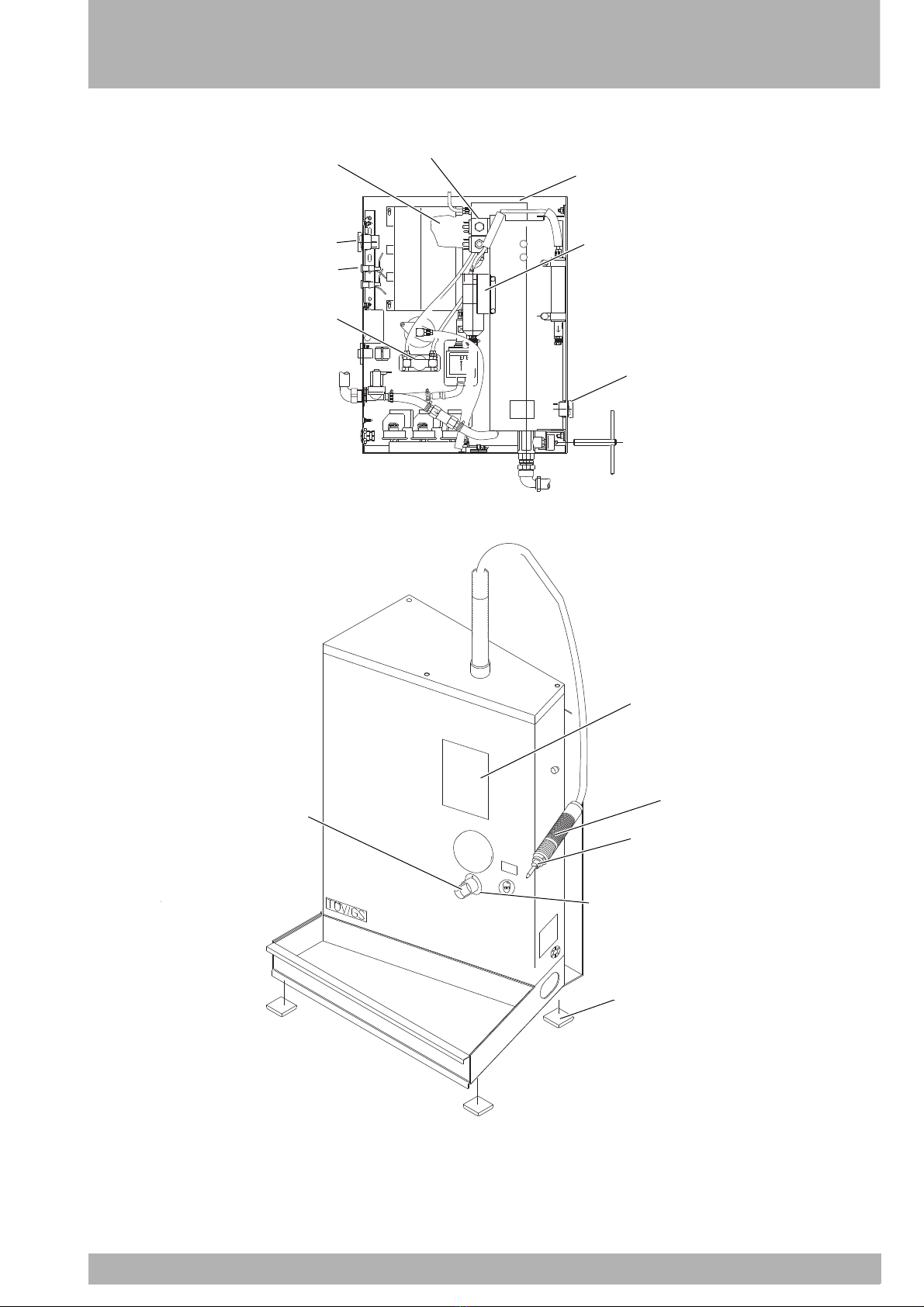

Steam Cleaner EWL 5839 1.000.8471 DE (ele tri al supply line 0.223.4129)

Steam Cleaner EWL 5839 1.000.9671 GB (ele tri al supply line 0.691.8281)

Steam Cleaner EWL 5839 1.000.9676 US (ele tri al supply line 0.692.5441)

Steam Cleaner EWL 5839 AU (ele tri al supply line 0.691.8531)

Voltage: 230 V / 50 Hz

Power: 7.5 Amps

Consumption: 1800 W

Prote tion lass: IP 43

Method of operation: Intermittent operation 5 / 5 min.

Working pressure: Max. 6 bar

Steam temperature: Max. 164° C at 6 bar indi ated

Boiler apa ity: 2.2 litres

Overall dimensions: Width 450 mm

Height 570 mm (to top of Housing)

750 mm (in l. Steam-spray hose)

Depth 330 mm

Weight: 31 Kg (plus 2 Kg for footswit h)

Noise emission levels for KaVo Steam Cleaners < 70 dB(A)

Warranty information

Within the s ope of the urrent Delivery and Payment Conditions, KaVo EWL warrants the unit to be free from malfun tions, defe ts in

both materials and workmanship for a period of 6 months from the date of pur hase. At the end of this warranty period, KaVo provides a

further 6-months guarantee for faults arising, whi h an be tra ed ba k to defi ien ies in materials or the manufa turing pro ess.

For established omplaints, the guarantee overs only the supply or repair of repla ements, free of harge. KaVo EWL is not liable for

defe ts, and their onsequen es, aused by or whi h ould be aused by normal wear; misuse; improper leaning or maintenan e; failure to

follow the operating, maintenan e or ele tri al regulations; orrosion; air pollution; hemi al or ele tri al influen es whi h are unusual, or

not in a ordan e with fa tory regulations.

The guarantee does not apply if defe ts, or onsequential damage, are the result of unauthorized modifi ations, and alterations to the

produ t. Entitlement to the guarantee an only be validated if laims are submitted without delay, in writing.

Return of the produ t must be a ompanied by a opy of the invoi e or delivery note, on whi h the serial number is learly indi ated.

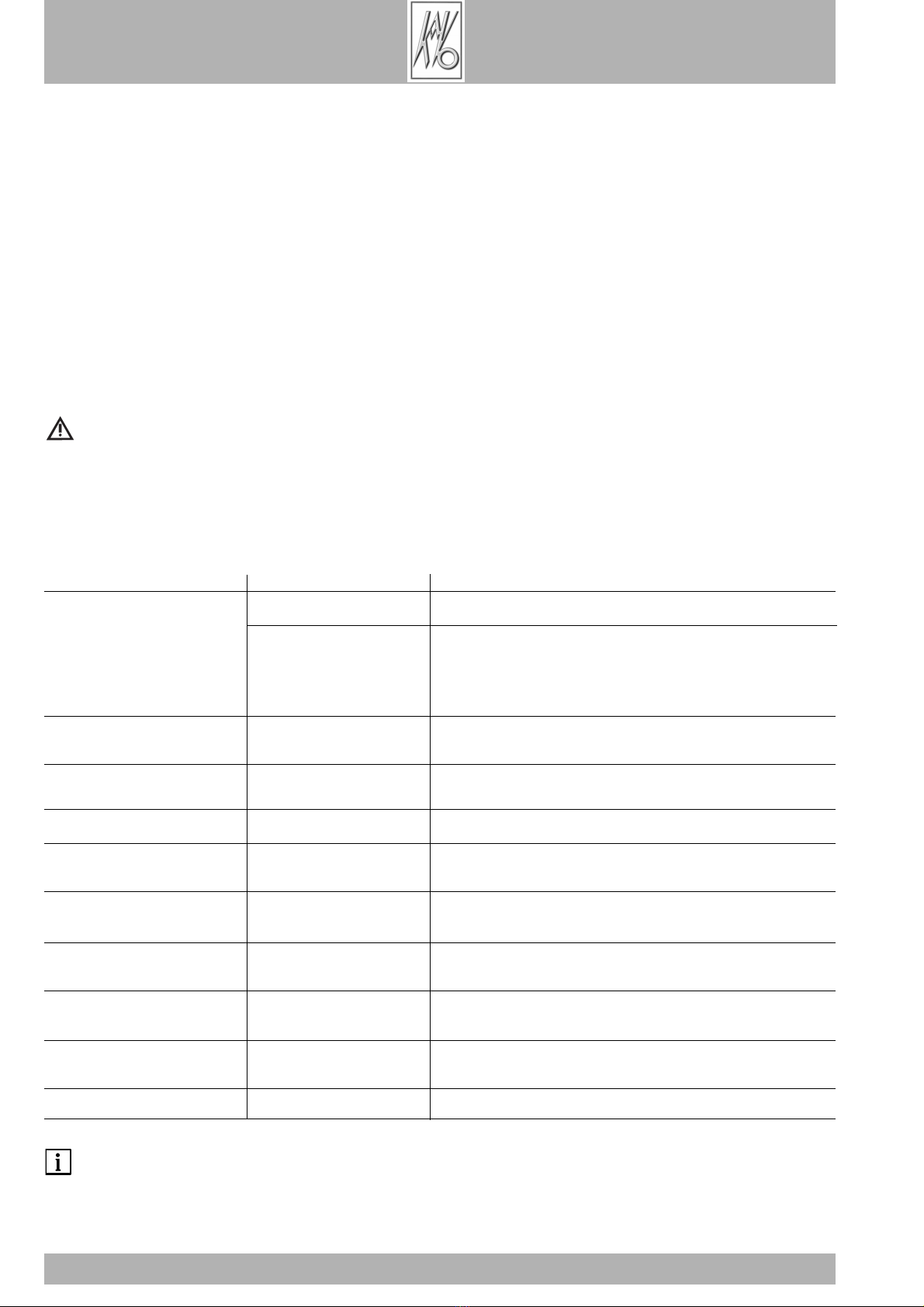

Accessories

Mat. No. Description

1.001.2156 Drawer, omplete (Colle tion tray)

1.001.2158 Lid for drawer

1.001.2159 Footswit h, omplete assembled

1.001.2160 Fixings set

1.001.2161 Angled tip for steam-nozzle (not in luded)

1.001.2162 Wall-mount, omplete

1.001.2163 Square so ket wren h

1.001.2164 Water drainage hose 1/2“, 1.5 metres long

1.001.2165 Water supply hose, grey, omplete – 3/4“ onne tion, 1.5 metres long

1.001.2166 Hose lips D12x20-9

1.001.2167 Hose onne tion 3/4“ – 90° elbow for 1/2“ hose