Table of Contents

ma_dr_e6-hf-filter-geh7-20344395_en iii

Table of Contents

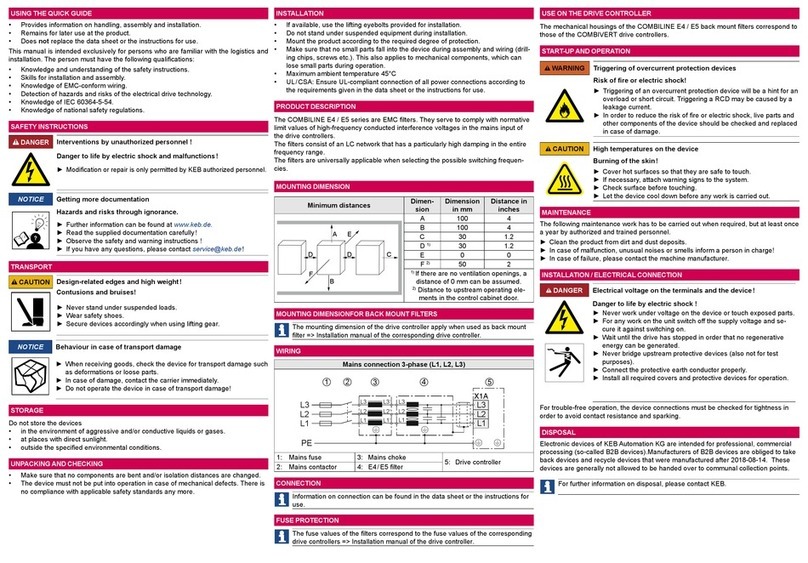

1 Introduction ................................................................................................................................................... 7

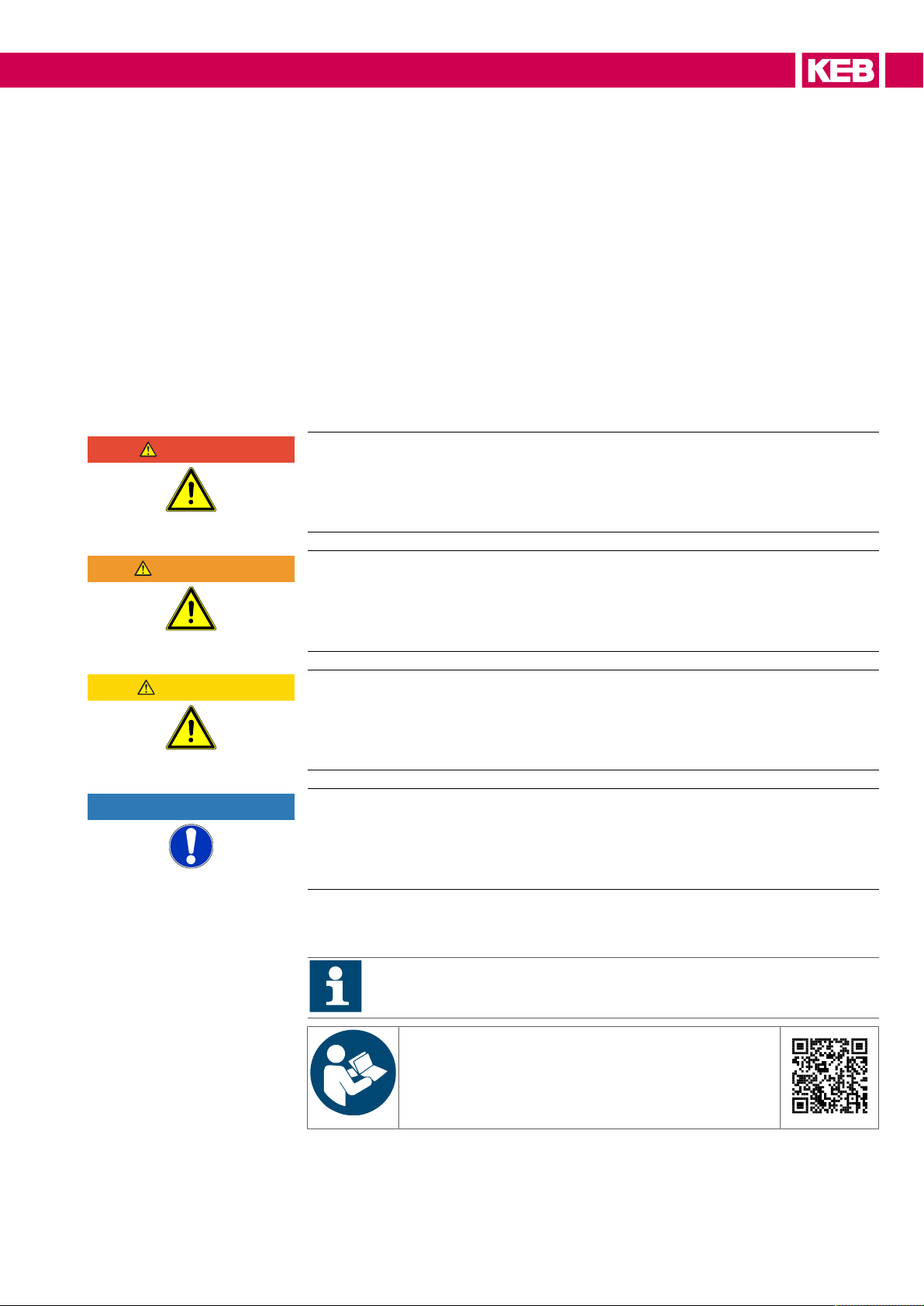

1.1 Markings................................................................................................................................................ 7

1.1.1 Warnings................................................................................................................................. 7

1.1.2 Information notes .................................................................................................................... 7

1.1.3 Symbols and markers ............................................................................................................. 8

1.2 Laws and guidelines.............................................................................................................................. 8

1.3 Warranty and liability............................................................................................................................. 8

1.4 Support.................................................................................................................................................. 8

1.5 Copyright............................................................................................................................................... 9

1.6 Validity of this manual ........................................................................................................................... 9

1.7 Target group.......................................................................................................................................... 9

2 General Safety Instructions.......................................................................................................................... 10

2.1 Installation............................................................................................................................................. 10

2.2 Electrical installation.............................................................................................................................. 10

2.3 Start-up and operation .......................................................................................................................... 11

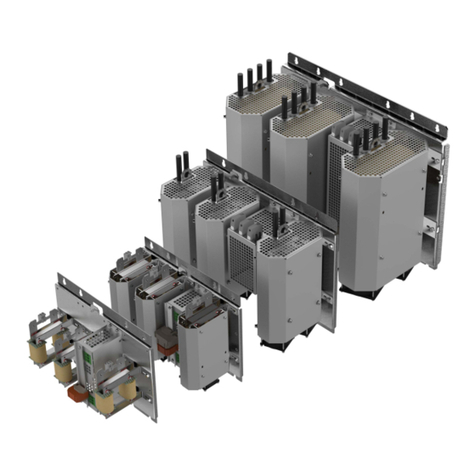

3 Product description ...................................................................................................................................... 12

3.1 Intendend use ....................................................................................................................................... 12

3.2 Unintended use..................................................................................................................................... 12

3.3 Part code............................................................................................................................................... 12

3.4 Functional description ........................................................................................................................... 13

3.4.1 IT mains filter .......................................................................................................................... 13

4 Technical data ............................................................................................................................................... 14

4.1 Operating conditions ............................................................................................................................. 14

4.1.1 Climatic ambient conditions .................................................................................................... 14

4.1.2 Mechanical ambient conditions............................................................................................... 14

4.1.3 Chemical/mechanical active substances ................................................................................ 14

4.1.4 Electrical operating conditions ................................................................................................ 15

4.2 Electrical data........................................................................................................................................ 15

4.2.1 NHF combinations .................................................................................................................. 15

4.2.2 Fuse protection according to .................................................................................................. 15

4.2.3 Fuse protection according to UL Class J ................................................................................ 16

4.2.4 Fuse protection according to UL type gR / aR........................................................................ 16

4.2.5 Interference suppression level................................................................................................ 16

4.2.6 Insertion loss........................................................................................................................... 16

5 Assembly ....................................................................................................................................................... 18

5.1 Assembly instructions ........................................................................................................................... 18

5.1.1 EMC notes on assembly......................................................................................................... 18

5.2 Mounting the filter/drive controller......................................................................................................... 19

5.3 Mounting direction................................................................................................................................. 19

5.4 Minimum installation distances filter with drive controller...................................................................... 20

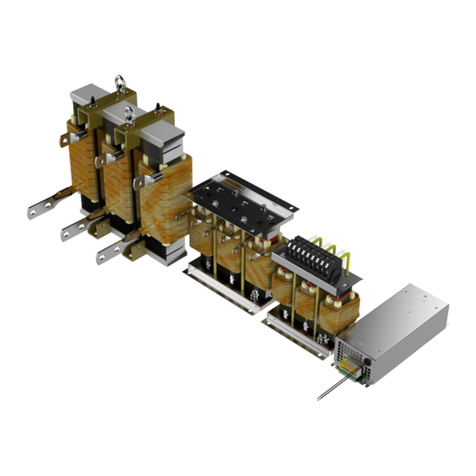

5.5 Assembly NHF combination.................................................................................................................. 20

5.6 Dimensions and weights ....................................................................................................................... 21

5.7 Fixing material....................................................................................................................................... 22

6 Electrical connection .................................................................................................................................... 23