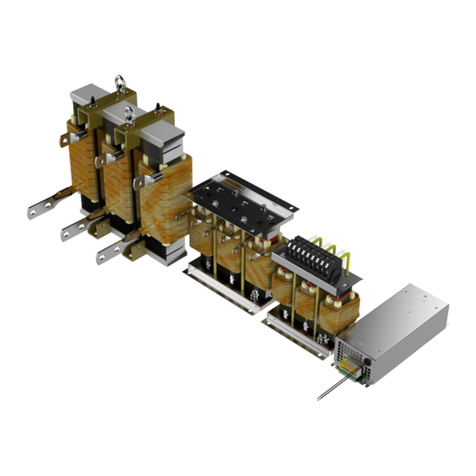

MOUNTING DIMENSION FOR THE USE AS SIDE MOUNT FILTER

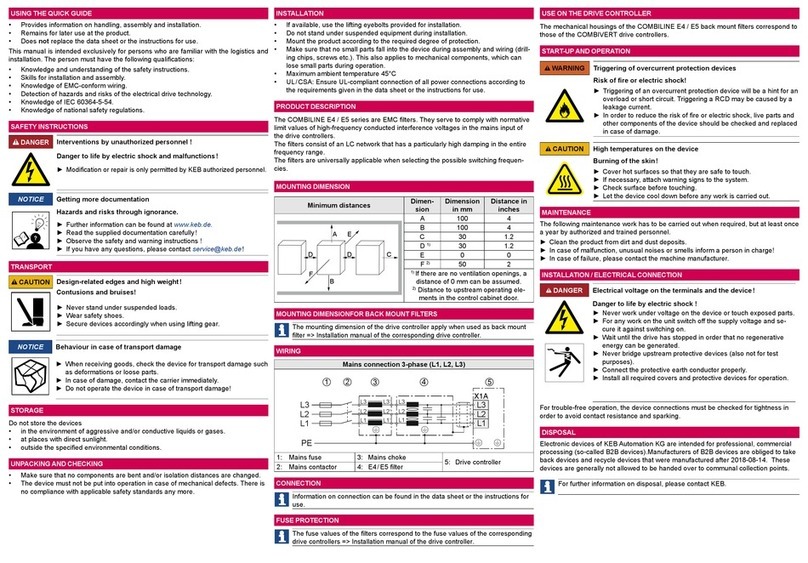

WIRING

CONNECTION

FUSE PROTECTION

USING THE QUICK GUIDE

• Provides information on handling, assembly and installation.

• Remains for later use at the product.

• Does not replace the electronically provided instructions for use.

This manual is intended exclusively for persons who are familiar with the logistics and installation. The person must have the

following qualications:

• Knowledge and understanding of the safety instructions.

• Skills for installation and assembly.

• Knowledge of EMC-conform wiring.

• Detection of hazards and risks of the electrical drive technology.

• Knowledge of IEC 60364-5-54.

• Knowledge of national safety regulations.

SAFETY INSTRUCTIONS

DANGER Interventions by unauthorized personnel !

Danger to life through electric shock and malfunctions !

► Modication or repair is only permitted by KEB authorized personnel.

NOTICE Getting more documentation

Hazards and risks through ignorance.

► Open the KEB homepage at www.keb.de.

► By entering the material number in the search eld, you will get the corresponding parts of the

instructions for use.

►Read the instructions for use carefully !

►Observe the safety and warning instructions !

TRANSPORT

The transport must be carried out by instructed persons, observing the following instructions.

CAUTION Maximum design edges and high weight !

Contusions and bruises!

►Never stand under suspended loads.

►Wear safety shoes.

►Secure devices accordingly when using lifting gear.

NOTICE Behaviour in case of transport damage

►When receiving goods, check the device for transport damage such as deformations or loose parts.

►In case of damage, contact the carrier immediately.

►Do not operate the device in case of transport damage!

STORAGE

Do not store the devices

• in the environment of aggressive and/or conductive liquids or gases.

• at places with direct sunlight.

• outside the specied environmental conditions.

UNPACKING AND CHECKING

• Make sure that no components are bent and/or isolation distances are changed.

• The device must not be put into operation in case of mechanical defects. There is no compliance with applicable safety

standards any more.

INSTALLATION

• If available, use the lifting eyebolts provided for installation.

• Do not stand under suspended equipment during installation.

• Mount the product according to the required degree of protection.

• Make sure that no small parts fall into the device during assembly and wiring (drilling chips, screws etc.). This also applies to

mechanical components, which can lose small parts during operation.

• The devices are intended for the use in a pollution degree 2 environment.

• Maximum ambient temperature 45°C

• UL / CSA: Ensure UL-compliant connection of all power connections according to the requirements given in the data

sheet.

The fuse values of the lters correspond to the fuse values of the corresponding drive controllers.

• Cable cross-sections and fuses must be dimensioned according to the design of the machine manufacturer. Specied

minimum / maximum values may not be fallen below /exceeded.

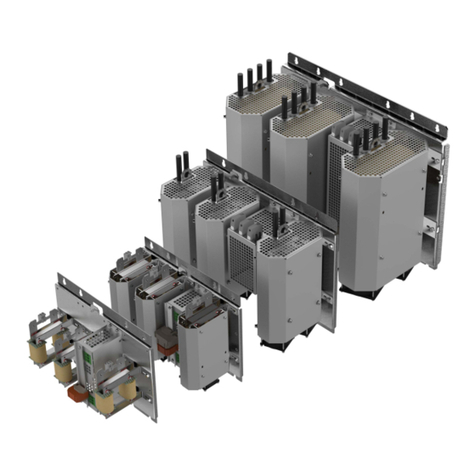

USE ON THE DRIVE CONTROLLER

The mechanical housing sizes of the COMBILNE E6 back mount lters correspond to those of the COMBIVERT F6 drive

controllers.

COMBILINE E6 COMBIVERT F6

Housing

2 (14E6T60-1050, 16E6T60-1050) 2

3 (18E6T60-1050, 20E6T60-1050) 3

4 (22E6T60-1050) 4

START-UP AND OPERATION

WARNING Triggering of overcurrent protection devices

Risk of re or electric shock!

►Triggering of an overcurrent protection device will be a hint for an overload or short circuit. Triggering

a RCD may be caused by a leakage current.

► In order to reduce the risk of re or electric shock, live parts and other components of the device

should be checked and replaced in case of damage.

CAUTION High temperatures on the device

Burning of the skin !

►Cover hot surfaces so that they are safe to touch.

►If necessary, attach warning signs to the system.

►Check surface before touching.

►Let the device cool down before any work is carried out.

MAINTENANCE

The following maintenance work has to be carried out when required, but at least once a year by authorized and trained

personnel.

►Clean the product from dirt and dust deposits.

►In case of malfunction, unusual noises or smells inform a person in charge!

►In case of failure, please contact the machine manufacturer.

INSTALLATION / ELECTRICAL CONNECTION

DANGER Voltage at the terminals and the device !

Danger to life by electric shock !

►Never work under voltage on the device or touch exposed parts.

► For any work on the unit switch o the supply voltage and secure it against switching on.

►Wait until the drive has stopped in order that no regenerative energy can be generated.

►Never bridge upstream protective devices (also not for test purposes).

►Connect the protective earth conductor properly.

►Install all required covers and protective devices for operation.

For a trouble-free and safe operation, please pay attention to the following note:

► Check for reliable t of the device connections in order to avoid contact resistance and sparking.

DISPOSAL

► For professional disposal, follow the instructions in the instructions for use

Minimum distances Dimension Dimension in mm Distance in inches

A 0 0

B100 4

C 30 1.2

D 0 0

E 0 0

F 1) – –

1) Distance to front operating elements in the control cabinet

door.

The mounting dimension of the drive controller apply when used as back mount lter.

Mains connection 3-phase (L1, L2, L3)

L1

L2

L3

L1

L2

L3

PE

➀ ➁ ➂ ➃ ➄

L1 L1‘ L1

L2 L2‘ L2

L3 L3‘ L3

1: Mains fuse 3: Mains choke 5: Drive controller

2: Mains contactor 4: E6 lter

Part No. Connection

Cross-sectional area

Cross-sec-

tion Tightening torque

in mm² / AWG

L1, L2, L3 PE Output L1, L2, L3 PE Output L1, L2, L3 PE Output

14E6T60-1050

Spring-

loaded

terminal

Spring-

loaded

terminal Strand

Betatherm

0.2...6 / 24...10 6 / 10

−

−

−

16E6T60-1050 0.75...25 / 18...4 10 / 8

18E6T60-1050 4...35 / 14...2 16 / 6

20E6T60-1050 4...35 / 14...2 35 / 2

22E6T60-1050

M6 bolt for

crimp

connector

10...50 /

8...1/0 −50 /

1/0

10 /

88

Fuse protection for IEC

Part No. Input voltage

Max. fuse size

Class gG

SCCR 30 kA

14E6T60-1050

400 V

25A

16E6T60-1050 50A

18E6T60-1050 80A

20E6T60-1050 100A

22E6T60-1050 160A

Fuse protection for UL

Part No. Input voltage

Max. fuse size

Class RK5 Class gG

SCCR SCCR 30 kA Type

5 kA 10 kA

14E6T60-1050

480 V

25A −25A SIBA 50 140 06.25

16E6T60-1050 50A −50A SIBA 50 140 06.50

18E6T60-1050 60A −

63A

SIBA 20 189 20.63

COOPER BUSMANN

170M1365

60A LITTELFUSE

L70QS060

20E6T60-1050 − 90 A

100A

SIBA 20 189 20.100

COOPER BUSMANN

170M1367

90 A LITTELFUSE

L70QS090

22E6T60-1050 −125A 125A

SIBA 20 189 20.125

COOPER BUSMANN

170M1368

A

B

D

E

F

C

D