KegLand BrewZilla 35L User manual

Other KegLand Brewing System manuals

KegLand

KegLand KL20671 User manual

KegLand

KegLand Fermzilla User manual

KegLand

KegLand KL14649 User manual

KegLand

KegLand BrewZilla 35L Gen 4 User manual

KegLand

KegLand Fermzilla User manual

KegLand

KegLand Fermzilla Unitank Series User manual

KegLand

KegLand KL20671 User manual

KegLand

KegLand KL10955 User manual

KegLand

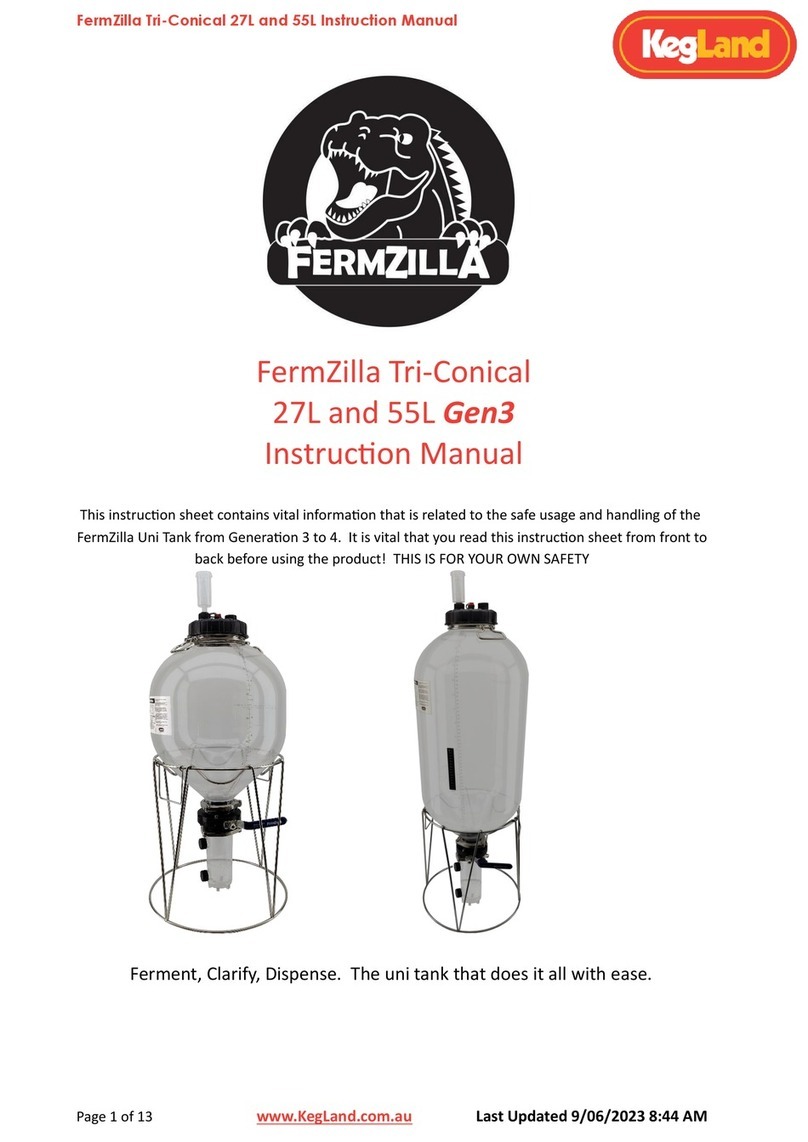

KegLand FermZilla Tri-Conical 27L Gen3 User manual

KegLand

KegLand Robobrew User manual

Popular Brewing System manuals by other brands

Animo

Animo ComBi CB5 user manual

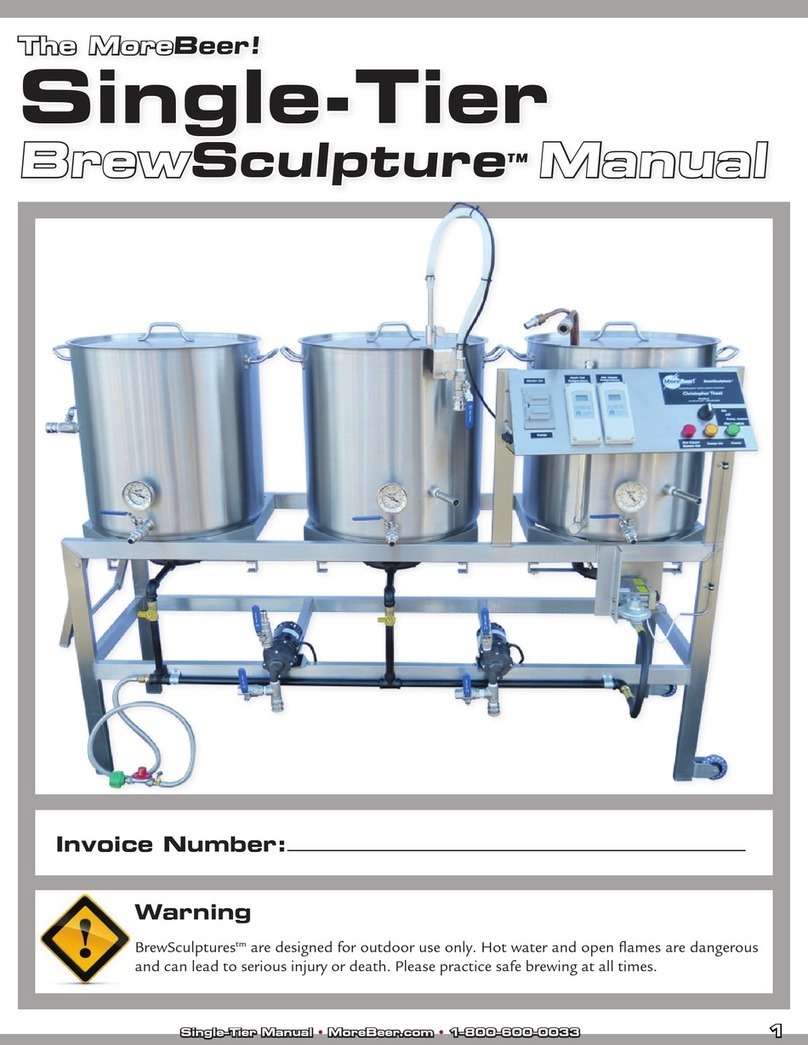

MoreBeer

MoreBeer BrewSculpture manual

Keurig Hot

Keurig Hot Commercial Series owner's manual

Keg King

Keg King KEGMASTER XL user manual

Blichmann Engineering

Blichmann Engineering BrewEasy Compact TC Assembly operation maintenance

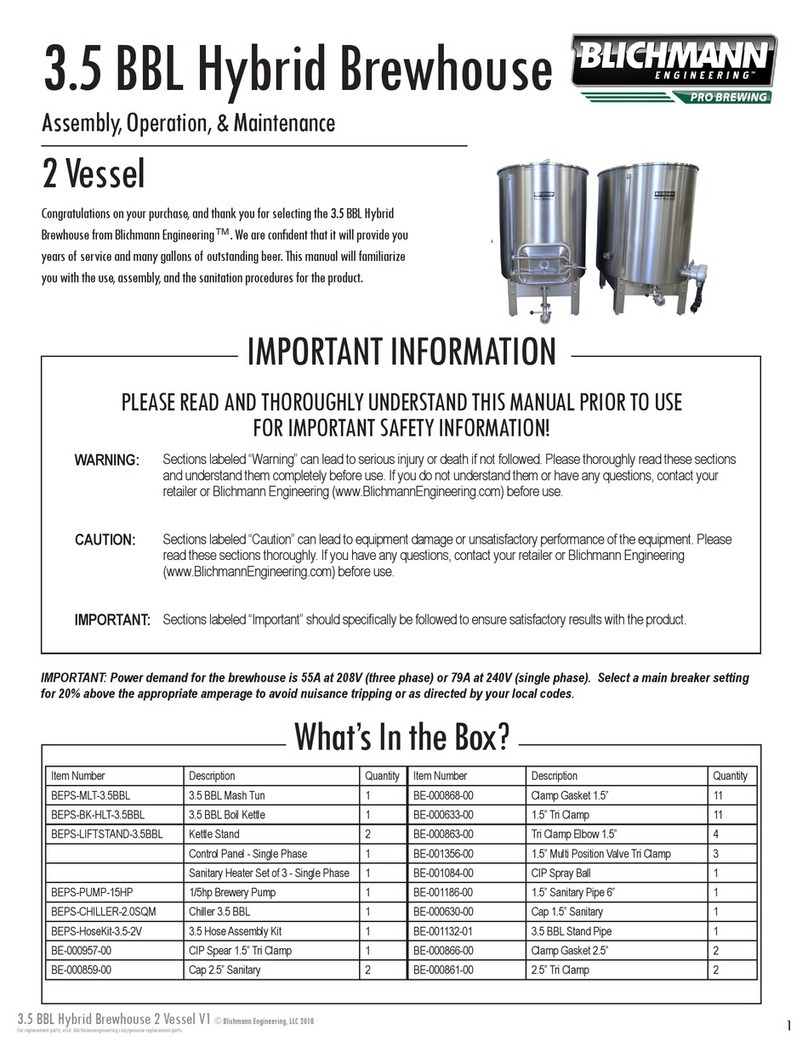

Blichmann Engineering

Blichmann Engineering 3.5 BBL Hybrid Brewhouse Assembly operation maintenance