List of Illustrations

SECTION 2 - Operation

Figure 2-l

Figure 2-2

Figure 2-3

Figure 24

Figure 2-5

Figure 2-6

Figure 2-7

Figure 2-8

Figure 2-9

Figure 2-10

Figure 2-11

Figure 2-12

Figure 2-13

Figure 2-14

Figure 2-15

Figure 2-16

Figure 2-17

Figure 2-18

Figure 2-19

Figure 2-20

Figure 2-21

Figure 2-22

Figure 2-23

Figure 2-24

Figure 2-25

Figure 2-26

Matrix Card Installation ..........................................

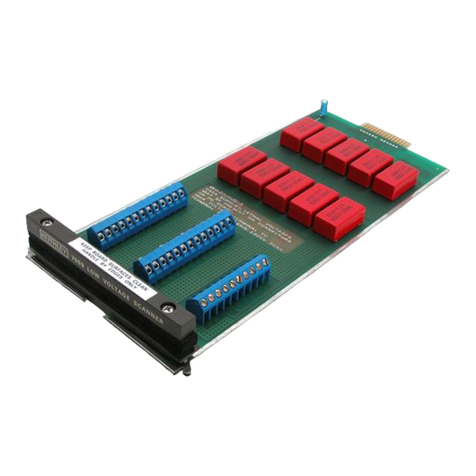

Model7076 ....................................................

Simplified Component Layout .....................................

Model 7076 Configured as4 x 24 Matrix ..............................

Model7076Configuredas8x12Matrix ..............................

Column Jumper Installation .......................................

Single-ended Switching Example (Using 7075-MTC Cable) ................

Differential Switching Example (Using High Isolation Cables) ..............

Driven Guard Example (Using High Isolation Cables) ....................

Sensing Example (Using High Isolation Cables) .........................

D-sub Receptacle Contact Assignments ...............................

Model 7075-MTC Standard Cable ...................................

D-sub Plug Pin Assignments for High Isolation Cables ...................

Schematic Drawing of Backplane Jumper Configuration (Factory Default) .....

Narrow Matrix Example (4 x 72) ....................................

Dual4x72Matrices ............................ .................

WideMatrixExample(8x36) ........................... . ..........

Partial Matrix Expansion (8 x 36) ....................................

Single Card System Example .......................................

Multiple Card System Example .....................................

Multiple Mainframe Example ......................................

Matrix/Multiplexer System .......................................

-3dB Bandwidth (Crosspoint Al closed, Rs = RL = 5OQ) ...................

-3db Bandwidth (Crosspoint HI2 closed, RS= RRL= 500) .................

Crosstalk (Crosspoints Gl and H2 closed, 5OQ source on ROW G, 500 load on

COLUMN l’, Measurements at ROW H) ..............................

Crosstalk (Cross

COLUMN 11, Mp oints All and 812 closed, 5On source on ROW A, 5OQ load on

easurements at ROW B) ..............................

SECTION 3 - Applications

Figure 3-l

Figure 3-2

Figure 3-3

Figure 34

Figure 35

Figure 3-6

Figure 3-7

Figure 3-8

Thick Film Resistor Network Testing

4-Terminal Ohms Measurements

Voltage Divider Checks . .

Transistor Testing . . .

Transistor Current Gain Checks .

Common Emitter Characteristics of an NPN Silicon Transistor

Transistor IE Measurements .

Transistor VsEMeasurements

.

2-26

......... 3-2

......... 3-3

......... 3-5

......... 3-6

......... 3-7

......... 3-8

......... 3-9

......... 3-10

2-3

24

2-5

2-6

2-7

2-8

2-8

2-8

2-9

2-9

2-10

2-12

2-14

2-16

2-17

2-18

2-18

2-20

2-21

2-22

2-23

2-24

2-25

2-25

2-26