Safety Precautions

The following safety precautions should be observed before using

this product and any associated instrumentation. Although some in-

struments and accessories would normally be used with non-haz-

ardous voltages, there are situations where hazardous conditions

may be present.

This product is intended for use by qualified personnel who recog-

nize shock hazards and are familiar with the safety precautions re-

quired to avoid possible injury. Read and follow all installation,

operation, and maintenance information carefully before using the

product. Refer to the manual for complete product specifications.

If the product is used in a manner not specified, the protection pro-

vided by the product may be impaired.

The types of product users are:

Responsible body

is the individual or group responsible for the use

and maintenance of equipment, for ensuring that the equipment is

operated within its specifications and operating limits, and for en-

suring that operators are adequately trained.

Operators

use the product for its intended function. They must be

trained in electrical safety procedures and proper use of the instru-

ment. They must be protected from electric shock and contact with

hazardous live circuits.

Maintenance personnel

perform routine procedures on the product

to keep it operating properly, for example, setting the line voltage

or replacing consumable materials. Maintenance procedures are de-

scribed in the manual. The procedures explicitly state if the operator

may perform them. Otherwise, they should be performed only by

service personnel.

Service personnel

are trained to work on live circuits, and perform

safe installations and repairs of products. Only properly trained ser-

vice personnel may perform installation and service procedures.

Keithley products are designed for use with electrical signals that

are rated Measurement Category I and Measurement Category II, as

described in the International Electrotechnical Commission (IEC)

Standard IEC 60664. Most measurement, control, and data I/O sig-

nals are Measurement Category I and must not be directly connect-

ed to mains voltage or to voltage sources with high transient over-

voltages. Measurement Category II connections require protection

for high transient over-voltages often associated with local AC

mains connections. Assume all measurement, control, and data I/O

connections are for connection to Category I sources unless other-

wise marked or described in the Manual.

Exercise extreme caution when a shock hazard is present. Lethal

voltage may be present on cable connector jacks or test fixtures. The

American National Standards Institute (ANSI) states that a shock

hazard exists when voltage levels greater than 30V RMS, 42.4V

peak, or 60VDC are present.

A good safety practice is to expect

that hazardous voltage is present in any unknown circuit before

measuring.

Operators of this product must be protected from electric shock at

all times. The responsible body must ensure that operators are pre-

vented access and/or insulated from every connection point. In

some cases, connections must be exposed to potential human con-

tact. Product operators in these circumstances must be trained to

protect themselves from the risk of electric shock. If the circuit is

capable of operating at or above 1000 volts,

no conductive part of

the circuit may be exposed.

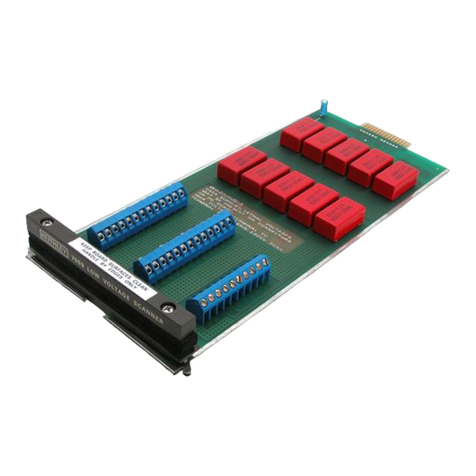

Do not connect switching cards directly to unlimited power circuits.

They are intended to be used with impedance limited sources.

NEVER connect switching cards directly to AC mains. When con-

necting sources to switching cards, install protective devices to lim-

it fault current and voltage to the card.

Before operating an instrument, make sure the line cord is connect-

ed to a properly grounded power receptacle. Inspect the connecting

cables, test leads, and jumpers for possible wear, cracks, or breaks

before each use.

When installing equipment where access to the main power cord is

restricted, such as rack mounting, a separate main input power dis-

connect device must be provided, in close proximity to the equip-

ment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any

other instruments while power is applied to the circuit under test.

ALWAYS remove power from the entire test system and discharge

any capacitors before: connecting or disconnecting cables or jump-

ers, installing or removing switching cards, or making internal

changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the com-

mon side of the circuit under test or power line (earth) ground. Always

make measurements with dry hands while standing on a dry, insulated

surface capable of withstanding the voltage being measured.

The instrument and accessories must be used in accordance with its

specifications and operating instructions or the safety of the equip-

ment may be impaired.

Do not exceed the maximum signal levels of the instruments and ac-

cessories, as defined in the specifications and operating informa-

tion, and as shown on the instrument or test fixture panels, or

switching card.

When fuses are used in a product, replace with same type and rating

for continued protection against fire hazard.

Chassis connections must only be used as shield connections for

measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is ap-

plied to the device under test. Safe operation requires the use of a

lid interlock.

5/03