MODELS 1792, 6422 INITIAL PREPARATION

2-7. MODEL 1792 INSTALLATION

2-8. The Model 1792 is installed internally in the

Model 177, 179, 179-20A, or 480 and is powered by

the instrument% line operated power supply. Instal-

lation of the Model 1792 precludes use of the Model

1788 Battery Pack. Refer to Figure 2-1 and install

the Model 1792 as fol lows:

‘t WARNI NC

Disconnect the line cord before removing the

case cover.

a. Turn off power and disconnect line cord.

-

b.

- Turn the DMM bottom side up and loosen the

four screws in the bottom cover.

c. Hold the top and bottom covers together to pre-

-

vent their separation and turn the DMM over to the

normal position.

d.

- Lift off the top cover and the calibration

shield if installed. If the Model 1788 Battery

Pack is installed, disconnect its connector from

the plug on the main printed circuit board and

remove the Model 1788. The four plastic spacers

must remain in place on the upright studs project-

ing through the main printed circuit board.

NOTE

Do not discard the calibration shield.

This shield must be installed during caii-

brat ion, as described in the Instruction Manual

for your instrument.

e.

- If the Model 1788 was removed, set the LINE/

BAT switch on the main printed circuitboard to the

LINE position.

f

-* Connect P1008 to its mating recepticle on the

printed circuit board (J1002 on the Model 480

and J1008 on the Models 177, 179 and 179-20A).

9 Install the Model 1792 in the instrument so that

it rests on the plastic spacers. The ground clip

must make contact with the upper side of the shield

on the Model 1792.

h

-0 Install the top cover that was shipped with

the Model 1792. Th is cover has a s lot to

accommodate the card edge connector of the Model

mm

i1rL.c ~

AL- Save all removed parts for reinstallation In

the event that the 1792 is to be removed at a

I ater date.

2-9. Model 1792 Output Connections.

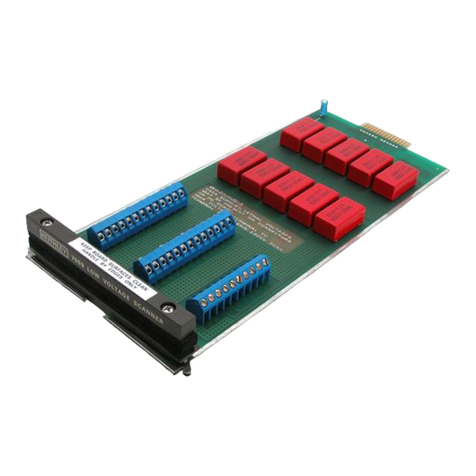

2-10. The Model 1792 uses a 26 pin card-edge

connector (P401) to provide all input and output

connections to external equipment. This connector

mates with a Keithley CS-294-1 flat-ribbon connector

(3M 3462 or equivalent), which is not supplied.

The output connector pins are identified in Table

2-l.

Two optional cable accessories are available for in-

terfacing the Model 1792 with external equipment.

The Model 1796 is a 10 foot (3 meter) flat ribbon

cable with 26 wires and an output mating connector

(CS-294-l) on one end. The other end is left

unterminated so that a connector can be installed

that is compatible with the equipment to be

interfaced. Pin identification for the Model 1796

is the same as that given in Table 2-l for the Model

1792 output connector. The wires are color coded

with the brown wire to pin 1, the red wire to pin 2,

and so on.

The Model 1797 is a 10 foot -(3 meter) cable that

provides the connections to interface the Model 1792

with the Keithley 750/7502 Line Printer. This cable

is plug-to-plug compatible with both the Model 1792

and Hodel 750/7502 for easy installation. Table 2-2

identifies the cable connector pins and wires.

2-3