Kemppi DCM User manual

Other Kemppi Welding Accessories manuals

Kemppi

Kemppi SuperSnake GT02SW User manual

Kemppi

Kemppi KempCool 10 User manual

Kemppi

Kemppi SuperSnake GTX User manual

Kemppi

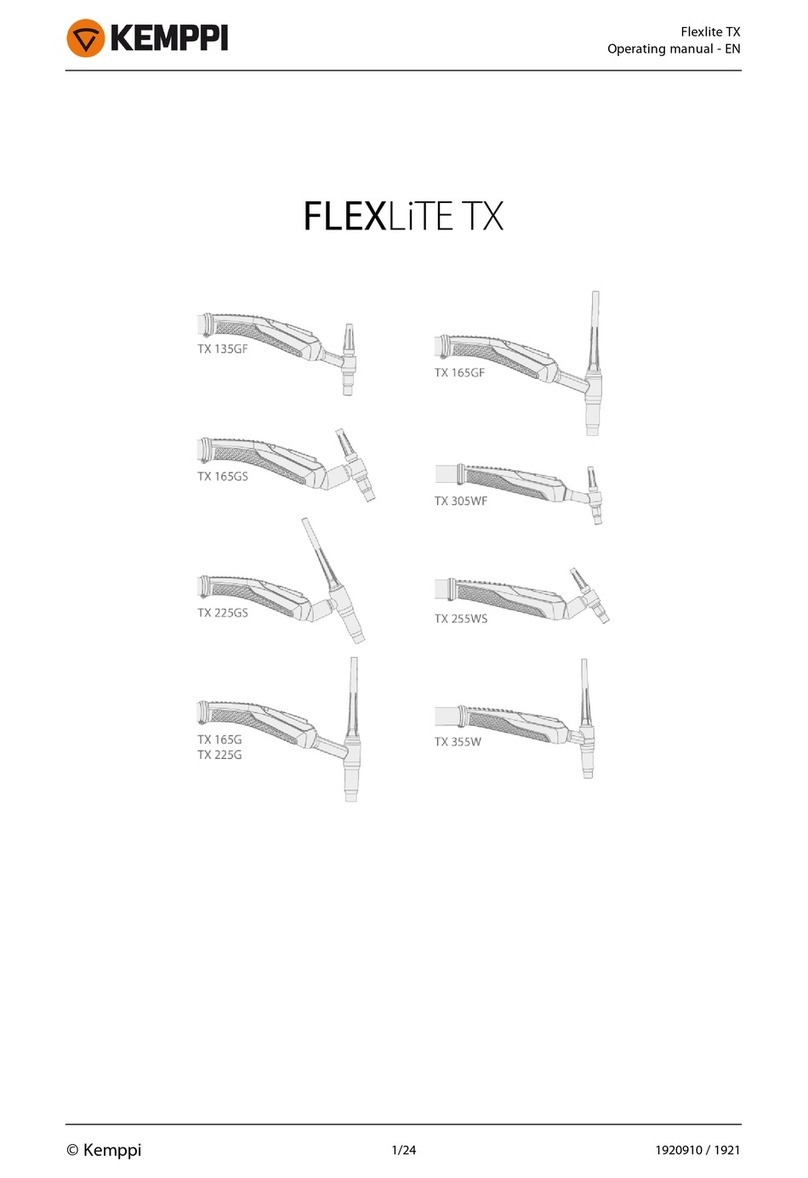

Kemppi FLEXLiTE TX Series User manual

Kemppi

Kemppi Flexlite GX Series User manual

Kemppi

Kemppi Flexlite GF User manual

Kemppi

Kemppi Flexlite GXe Series User manual

Kemppi

Kemppi MMT series User manual

Kemppi

Kemppi HiFeed User manual

Kemppi

Kemppi A3 MIG Rail System 2500 User manual

Kemppi

Kemppi X8 SuperSnake GT02XW User manual

Kemppi

Kemppi MTP 350 User manual

Kemppi

Kemppi SuperSnake GTX04HD User manual

Kemppi

Kemppi SA 60 User manual

Kemppi

Kemppi Beta e90 PFA User manual

Kemppi

Kemppi Gamma 100P User manual

Kemppi

Kemppi SA 35 User manual

Kemppi

Kemppi SuperSnake GT02S User manual

Kemppi

Kemppi Flexlite TX 133 User manual

Kemppi

Kemppi Delta 90 SFA User manual