www. kenall.com P: 800-4-Kenall F: 847-360-1781 1020 Lakeside Drive Gurnee, Illinois 60031

2

INSTALLATION INSTRUCTIONS

S511-092613

Uneven Surface Mounting Plate

1. Read all xture markings and labels to insure correct installation of the xture. Additional information may be

located on the xture, separate from this instruction sheet, regarding orientation and mounting restrictions.

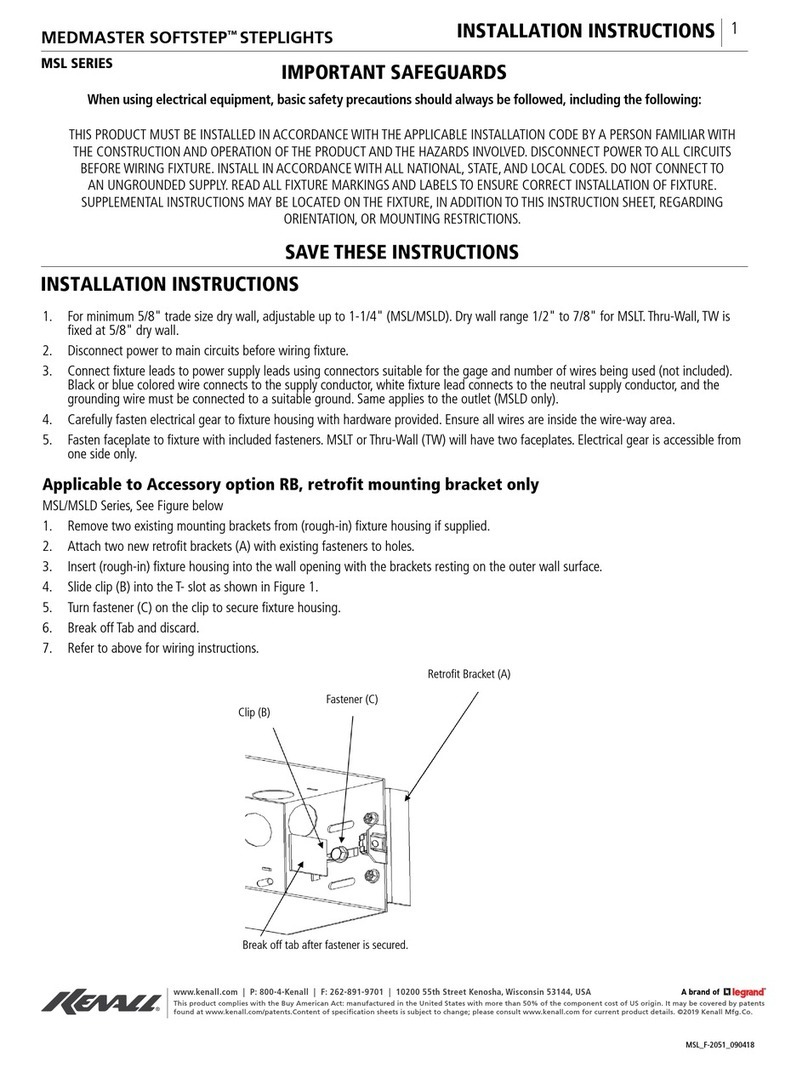

If the xture is to be mounted on uneven surfaces, in wet or damp locations, such as concrete block or brick

masonry, the mounting plate must be used and installed per these instructions. 1/4 diameter fasteners and

appropriate anchors must be used.

2. Disconnect power to the circuit before beginning work.

3. Use Mounting Plate as a template and mark the 4 mounting holes. Drill pilot holes in the mounting surface

appropriate for the anchor being used, and install anchors. To insure the xture’s watertight integrity, especially

if the xture is mounted in direct exposure to the elements, caulk between the mounting surface and Plate

using a high quality caulking material. Apply a full, continuous bead of caulk in an upside down “U” shape to

the back of the mounting plate to the outside of all mounting holes.

4. Disassemble Sentinall™by removing diffuser and reector. Using fasteners appropriate for the anchors, (not

supplied), align xture base over Mounting Plate, insert fasteners through xture base and Mounting Plate into

anchors in building. Gasket on back of xture base should form a tight seal to the Mounting Plate.

5. Connect xture leads to power supply leads using connectors suitable for the gauge and number of wires being

used (not included). Black xture lead connects to the supply conductor, white xture lead connects to the

neutral supply conductor, and the grounding wire must be connected to a suitable ground.

6. Install lamp, reector and diffuser to base using Torx®fasteners (included) and 9500 screwdriver (ordered

separately). On very uneven surfaces, additional caulking may be necessary to ll gaps between building and

Mounting Plate. Run caulk bead around perimeter of Mounting Plate.

Uneven Surface Mounting - Damp or Wet Locations

1. Read all xture markings and labels to insure correct installation of the xture. Additional information may be

located on the xture, separate from this instruction sheet, regarding orientation and mounting restrictions.

When mounting adapter to wall, casting must be oriented with long dimension vertical so that xture can be

installed with lamp base up.

2. Disconnect power to the circuit before wiring xture.

3. Locate and drill 2 pilot holes in mounting surface. Use surface adapter as template. Using 1/4-20 fasteners and

anchors appropriate for the mounting surface, (not supplied), mount surface adapter to building. Attach surface

conduit to back entry, or if side entry is used, remove side plug, and install in back conduit opening. All unused

openings must be plugged.

4. Connect xture leads to power supply leads using connectors suitable for the gauge and number of wires being

used (not included). Connections are to be made in the surface adapter. Black xture lead connects to the

supply conductor, white xture lead connects to the neutral supply conductor, and the grounding wire must be

connected to a suitable ground.

5. Mount wired baseplate to casting using the single No. 10-24 x 5/8 screws provided. Install lamp. Mount

diffuser/refractor to base using Torx®fastener (included) and 9500 screwdriver (ordered separately).

NOTE: To ensure the xtures watertight integrity, especially if the xture is mounted in direct exposure to the

elements, caulk between the mounting surface and base using a high quality caulking material.

ACCESSORIES: Photocontrolls-To prevent cycling, xture must be installed so that indirect xture light or other

ambient light is not visible to photocell. If xture cycles it is not a xture defect. In some cases additional hood (C-

1076) may help. Contact Factory.