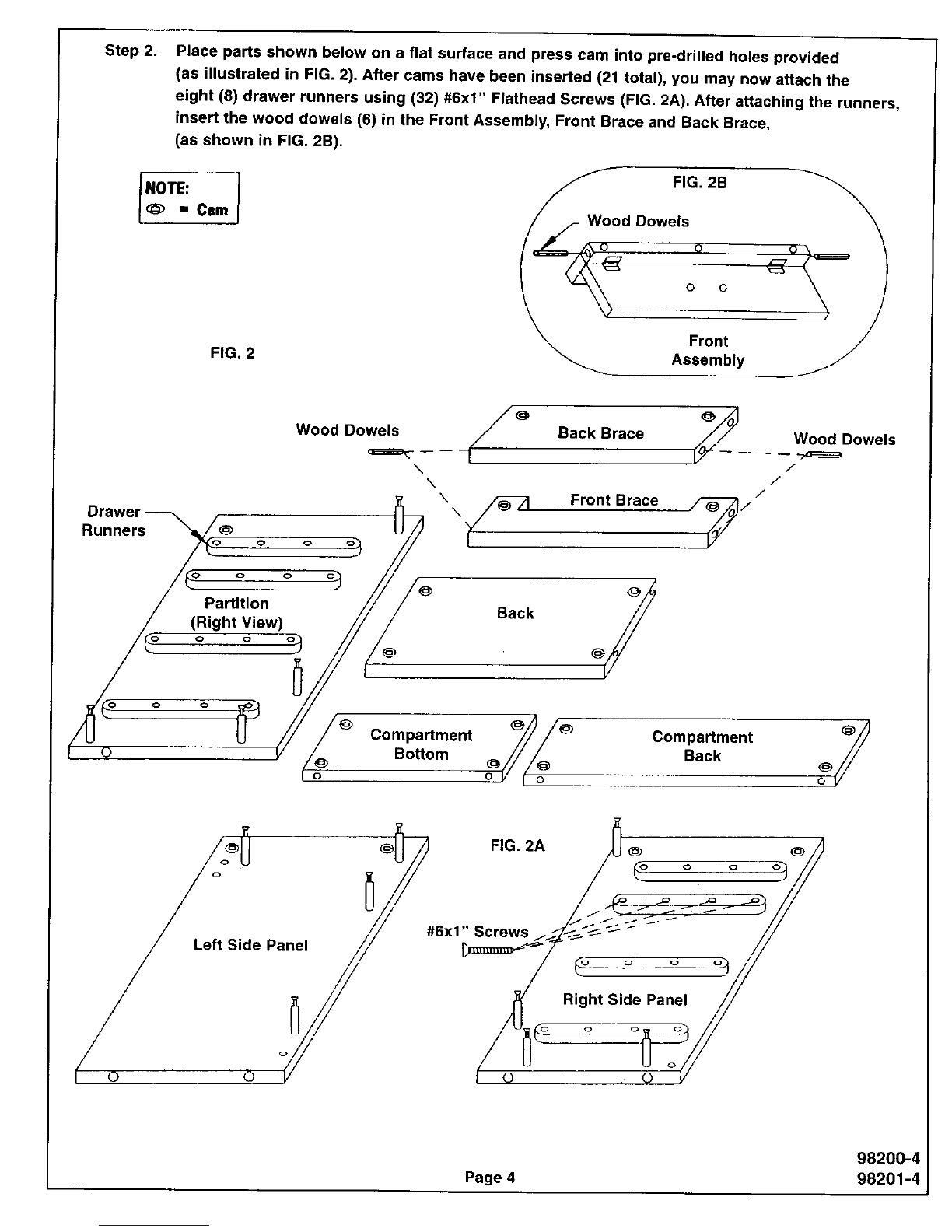

NOTE: The following assemblies should be done

with Cabinet upright.

Step 9. Attach Hinges to Leaf Supports with

(4) #8x518" Flathead screws each,

tap Magnet with hammer, (as shown

in FIG. 8A). Attach Bronze Strikes to

outside of Left and Right sides with #5xl/2"

Flathead Screw as in FIG. 8. Attach Self

Sticking Rubber Tab to the top outside edge of

each Leaf Support, as in FIG. 8A. Attach Leaf

Support to right and Left Sides with (8) #8x5/8"

Flathead Screws. Wings should fold to back of

cabinet (see FIG. 8).

#8x5/8" Round

Flathead Magnet

Screw_oo_--

FIG. 8A

Self Sticking

Rubber Tab

CAUTION: When applying the SELF STICKING RUBBER TAB,

CAREFULLY REMOVE THE WHITE PAPER BACKING ONLY.

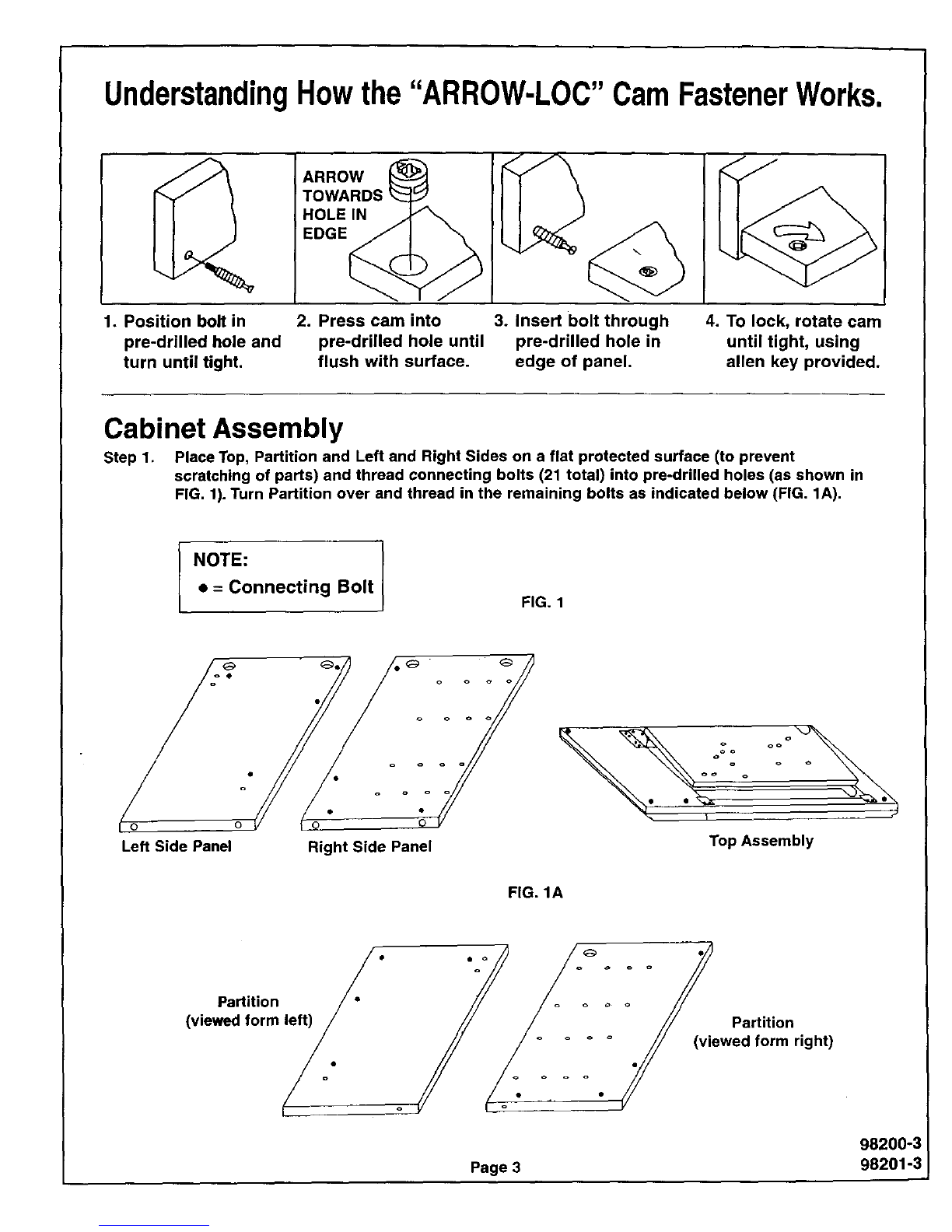

Step 10. Attach the Front Support to the cabinet Partition

•using (2) #5xl/2" Flathead Screws (as shown in

FIG. 9). Tension can be adjusted on the Front

Support by tightening the adjustment screw (as

shown in FIG. 9A).

FIG. 9

Partition

#5x1/2" [1_--__ ._ _._

Flathead Screws_\- _

Front Support -_

FIG. 8

Tension

Adjustment

FIG. 9A

rt

Step 11. Turn the Top over (with Platform hanging down)

and guide the Connecting Bolts into the holes on

the top edge of the Sides and Partition. Open

leaves to rest on Leaf Supports. Reach through

the opening in the Top and turn Cams to the

Locked position (as shown in FIG. 10). Now reach

into the Compartment and Lock the Cams in the

same manner.

Page 7

Top/Base Assembly 98200-7

98201-7