2 3

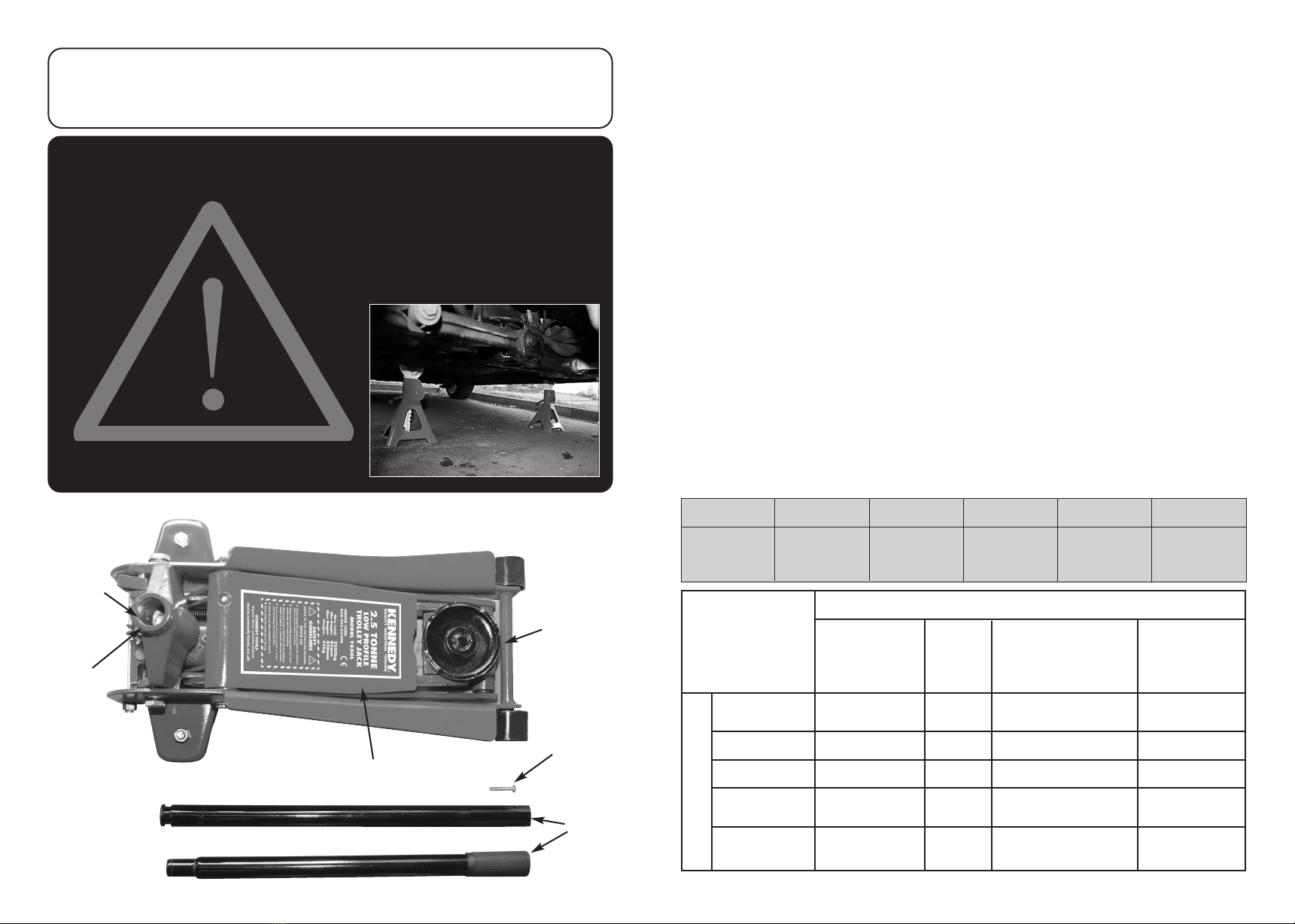

IDENTIFICATION

Saddle

Release

Valve

KENNEDY

Trolley Jacks are designed to help you work safely and efficiently.

Lifting equipment can be dangerous if the correct operating and maintenance

procedures are not followed. Operating instructions and basic safety procedures are

as follows:

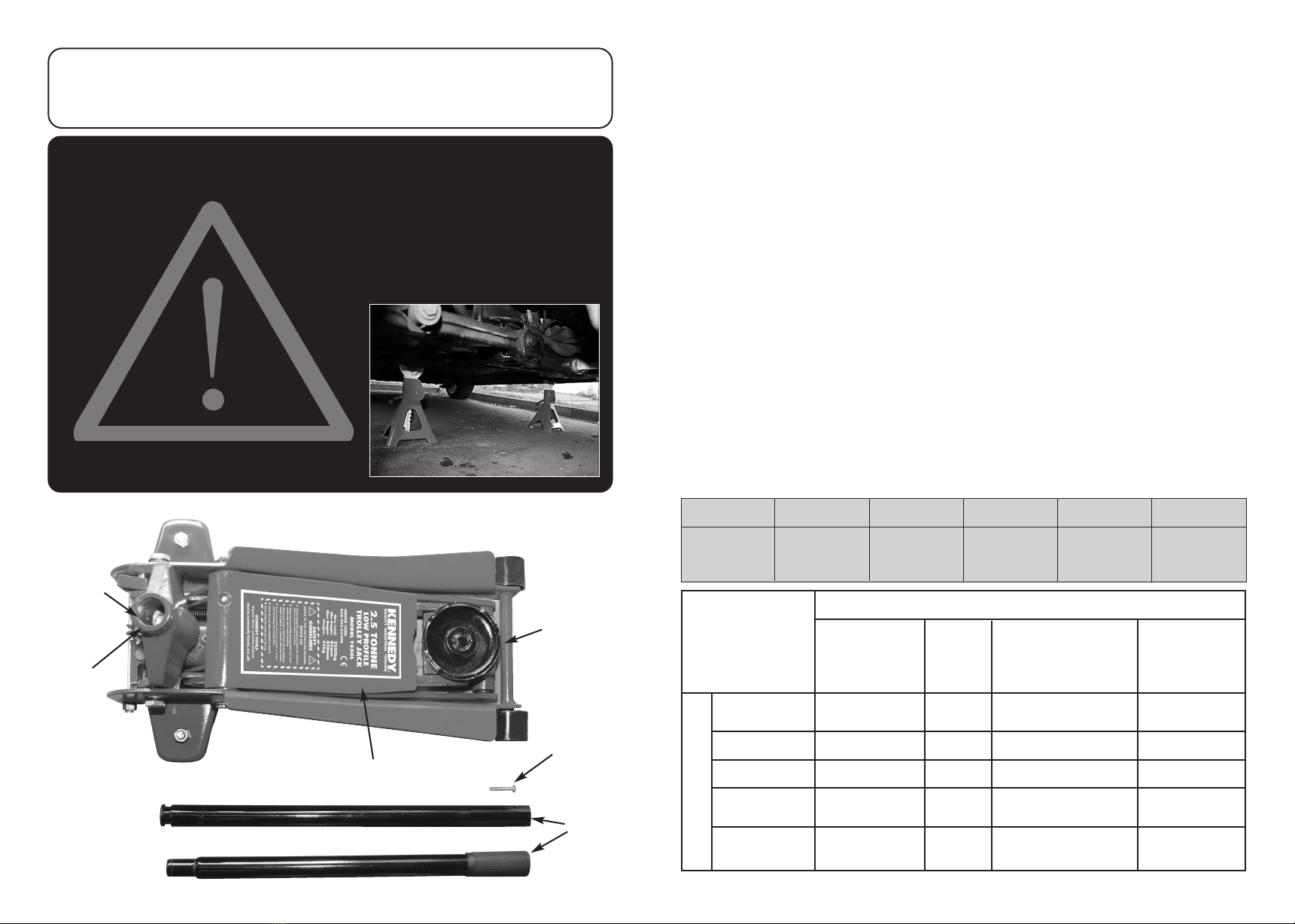

SAFETY GUIDELINES

lAlways use on specified jacking points, on a level surface and with a solid

foundation.

lBefore use inspect the Garage Jack for abnormal conditions such as cracked

welds, damage, worn, loose or missing parts. Also check that the jacking

points are not corroded before use.

lAlways place chocking wedges either side of the wheels and engage the

handbrake before the vehicle is lifted to

prevent wheel movement.

lAlways use correctly rated axle stands as

an additional means of support when work

under a lifted load.

lNever exceed the rated load capacity or

tamper with the factory set overload valve.

lNever lean against the raised vehicle.

lNever modify the jack, it is not designed to

support extensions or cradles and could

become unsafe.

OPERATING INSTRUCTIONS

ASSEMBLY

1. emove the wire clip securing the handle socket.

2. Using the hexagonal bolt provided secure and fasten the

two pump handle poles together.

3. Place the completed pump handle into the handle socket

and tightly secure.

OPERATE

Bleed the hydraulic system of air before using the

jack for the first time (see bleeding the system).

1. To engage piston pressure, turn the pump handle

clockwise.

2. Position the Jack under the vehicle so that the lifting

saddle will be centred on a specified jacking point.

3. Pump the handle to raise the load.

4. Once the load has been raised to the required height, use

an additional support (i.e. correctly rated stands) before

continuing work.

5. To lower the vehicle, remove the additional supports.

Turn the pump handle counterclockwise, this will turn the

release valve. The speed at which the vehicle is lowered

can be controlled by how quickly the release valve is

turned.

MAINTENANCE

We recommend that maintenance is carried out on the

Trolley Jack on a monthly basis to keep it operational.

1. Lubricate the ram, linkages, saddle and pump mechanism

with light oil.

2. Clean all surfaces and maintain all labels and warnings.

3. Check and maintain the ram oil level.

4. Check the ram every 3 months for any sign of rust or

corrosion. Clean as needed and wipe with an oiled cloth.

When not in use always keep the saddle and ram in the

fully lowered position.

5. Visually inspect for cracked welds, damaged, loose,

missing parts or hydraulic oil leaks.

6. You should always inspect the Trolley Jack immediately if

it has been subjected to abnormal load or shock.

If the Trolley Jack is found to have been damage in any way,

worn or operates abnormally in any way it should be removed

from service until repaired by an authorized person.

Owners and operators should be aware that repair of this

product may require specialized equipment.

Do not use brake or transmission fluids or regular motor oil as

they can damage the seals. Always use a medium grade

Hydraulic Oil.

REFILLING OIL RESER OIR

1.Turn the release valve counterclockwise to allow the ram

to fully retract.

2.With the jack in the level position, remove the rubber oil

fill plug. Stand the jack in a vertical position with the

handle socket down. The oil should be level with the

bottom of the fill hole. If not add more clean hydraulic jack

oil until level with the bottom of the fill hole.

3. eplace rubber oil fill plug.

4. Check that the Trolley Jack is fully operational and bleed

air from system as required.

BLEEDING THE SYSTEM

1. Turn the release valve counterclockwise no more than one

complete turn.

2. emove the rubber oil fill plug.

3. Pump the handle several times to force out any air.

4. Turn the release valve clockwise until it can no longer be

turned.

5. eplace the rubber oil fill plug.

STORAGE

Always store your jack in the fully lowered position. This will

help protect critical areas from corrosion.

The release valve has

not been full closed.

Turn the release

valve clockwise until

it can no longer be

turned.

The oil level

is low.

See refilling

instructions.

The h draulic s stem has

become blocked b dirt

particles. Manuall pull the

piston up. Turn the release

valve anti-clockwise and push

the piston down quickl .

Air has entered the

h draulics. See

bleeding the h draulic

s stem instructions.

The h draulic

s stem will not full

extend.

The jack will not lift

the rated load.

The jack lowers

under load.

The h draulic

s stem will

not lower.

The handle

raises or springs

back under load.

ll

ll

ll l

l

l

COMMON FAULTS

FAULT

FINDER

SOLUTIONS

Model Max Load Min Height Max Height Weight Order Code

Number (Kg/Tonne) (mm) (mm) (Kg) KEN-503

T359L 2,000/2 89 359 14.5 -6520K

T450L 2,500/2.5 85 450 36 -6530K

T510L 2,000/2 76 510 42 -6570K

T525L 3,000/3 140 525 50 -6580K

CAPACITIES

Pump

Handle

Handle

Socket

Ram

Hexagonal

Bolt