4 5

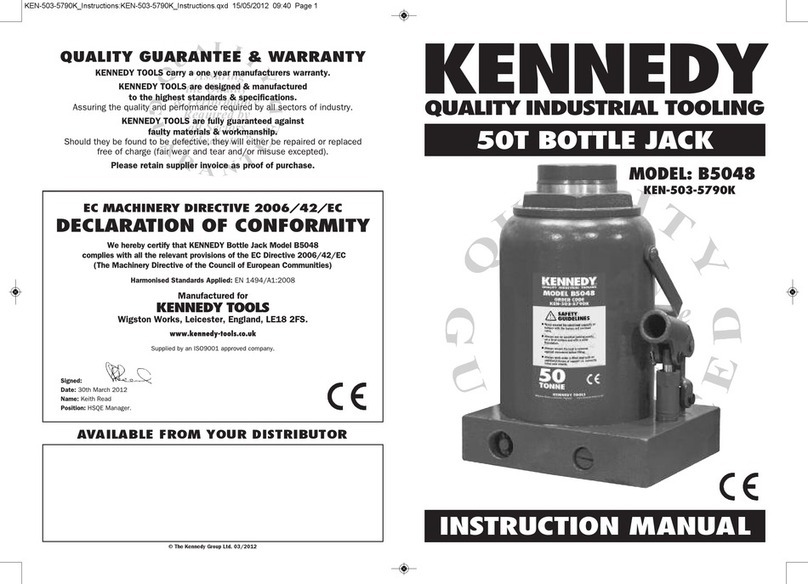

OPERATING

Before using the trolley jack for the first time, bleed the hydraulic system to remove any air.

Please see page 6 for bleeding instructions.

1. Turn the release valve clockwise until it can no longer be turned (See fig. 3).

2. Lower the handle to a convenient angle by pulling the control rod up (See fig. 4). Ensure the control rod is

locked into position in one of the three holes.

3. Pump the foot pedal to move the saddle to just under the correct height (See fig 5).

4. Use the toe plate to help position the trolley jack underneath the

vehicle (See fig. 6).

5. To help with positioning, the handle can also be locked in three

positions (See fig.7)

6. Pump the handle to raise the saddle into the correct position. Please

refer to the “Car owner’s manual” for the correct jacking points.

7. Check positioning under a slight load to make sure the jack will not slip

when in use (See fig 8). Continue to lift the load.

8. nce the load has been raised to the required height, use an additional

support (i.e. correctly rated stands) before continuing work (See fig 9).

9. To lower the vehicle, remove the additional supports. Turn the handle

anti-clockwise. The speed at which the vehicle is lowered can be

controlled easily by how much and how quickly the release valve is

turned.

TOOLS EEDED: Either two 17mm

sockets or two 17mm spanners.

1. Remove and dispose of the

metal rod which is holding the

handle socket down (See fig. 1).

2. Position the handle over the

spring. Push it down whilst

ensuring that the control rod is

located in the top securing hole

(See fig. 2). Tighten the handle

bolt securely and test to make

sure the handle will not pull out.

A EMBLY

fig. 2

fig. 1

fig. 3

fig. 5 fig. 6

fig. 9

fig. 7 fig. 8

fig. 4

TROUBLE HOOTING

PO IBLE CAU E

1. Low oil level.

2. Air has entered the hydraulics.

3. Ram seal leaking.

1. The release valve has not been fully

closed.

2. The oil level is low.

1. The release valve has not been fully

closed.

2. The oil level is low.

3. The hydraulic system has become

blocked by dirt particles.

1. The hydraulic system has become

blocked by dirt particles.

1. The hydraulic system has become

blocked by dirt particles.

1. Worn or damaged seals.

1. Low oil level.

2. Air in the system.

OLUTION

1. Fill to correct oil level.

2. Bleed the hydraulic system.

3. Replace worn seals

1. Turn the release valve clockwise until

it can no longer be turned.

2. See refilling instructions.

1. Turn the release valve clockwise

until it can no longer be turned.

2. See refilling instructions.

3. Turn the release valve anti-clockwise

and push the piston down quickly.

1. Turn the release valve anti-clockwise

and push the piston down quickly.

1. Turn the release valve anti-clockwise

and push the piston down quickly.

1. Replace worn seals. Look for

excessive contamination or wear.

Replace contaminated oil.

1. Fill to correct oil level.

2. Follow instructions to bleed air from

the system.

FAULT

Unit fails to extend or

extends partially.

The jack will not lift the

rated load.

The jack lowers under

load.

The hydraulic system

will not lower.

The handle raises or

springs back under load

Ram leaks hydraulic oil.

Incomplete or spongy

cylinder response when

foot pedal is pumped.

Repairs must be performed in a dirt-free environment by a qualified person who is familiar with this type

of equipment.

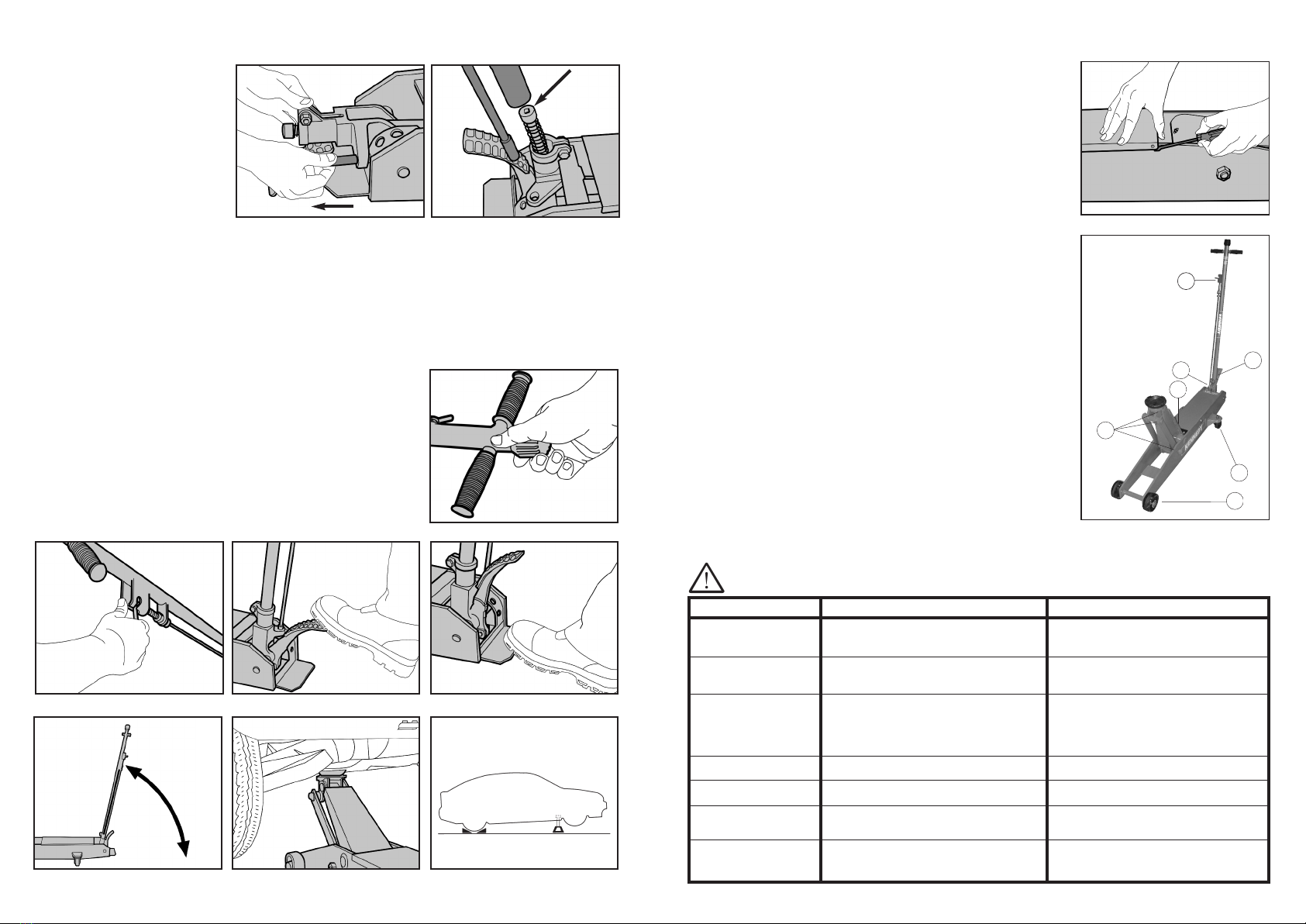

CARE & MAINTENANCE

Periodically check the operation of the jack. Ensure all nuts are fully

tightened and all other fixings are in position and secure. Do not use the

trolley jack if you suspect a fault but refer to the fault finder section below.

To gain access to the hydraulic pump, remove the cover plate using a flat

headed screwdriver (See fig 10).

CHECKING & FILLING THE OIL RE ERVOIR:

1. Place the jack on level ground

2. Always follow the precautions advised by the oil manufacturer.

3. Lower the jack to the lowest position.

4. Remove the rubber filler plug from the cylinder housing. Using hydraulic

oil ISO VG.22.32, fill until the inner cylinder is covered. D N T USE

BRAKE FLUID.

5. Pump the trolley jack unloaded 5 or 6 times to expel air.

6. Add more oil if necessary.

7. Refit the filler plug.

BLEEDING THE Y TEM:

1. Turn the release valve anti-clockwise no more than one complete turn.

2. Remove the rubber oil stopper from the cylinder housing.

3. Pump the handle several times to force out any air.

4. Turn the release valve clockwise until it can no longer be turned.

5. Replace the rubber stopper.

LUBRICATING:

Lubricate the points as indicated in fig.11.

a. HA DLE. Use light oil on moving parts.

b. REAR WHEELS. Use light oil on axles and castor bearings.

c. LIFTI G ARM. Inject grease into grease fitting.

d. SADDLE & LI KAGE. Use light oil on all moving and pivoting parts.

e. HA DLE SOCKET PIVOT BOLTS. Use light oil to lubricate pivot bolts.

f. FOOT PEDAL. Use light oil on moving parts.

g. FRO T WHEELS. Inject grease into grease fitting.

WHEN NOT IN U E:

Wipe clean with a slightly oiled cloth. Store with the release valve open.

a

e

d

c

b

g

f

fig. 10

fig. 11