REV C: 12/24/13

OPERATING INSTRUCTIONS

ONLY TRAINED PERSONNEL ARE TO OPERATE THIS TOOL.

1. TO ENSURE TOOL IS OPERATING PROPERLY, PERFORM FOLLOWING STEPS AT START OF EACH SHIFT.

•MAKE SURE TOOL MOVES UP AND DOWN FREELY WHILE HANGING FROM BALANCER OVERHEAD.

• WITH POWER TO TOOL TURNED ON, TEST TRIGGER FOR PROPER OPERATION.

• DEPRESS EACH TRIGGER SEPARATELY. TOOL SHOULD NOT ACTIVATE. DEPRESS BOTH TRIGGERS. TOOL

SHOULD ACTIVATE.

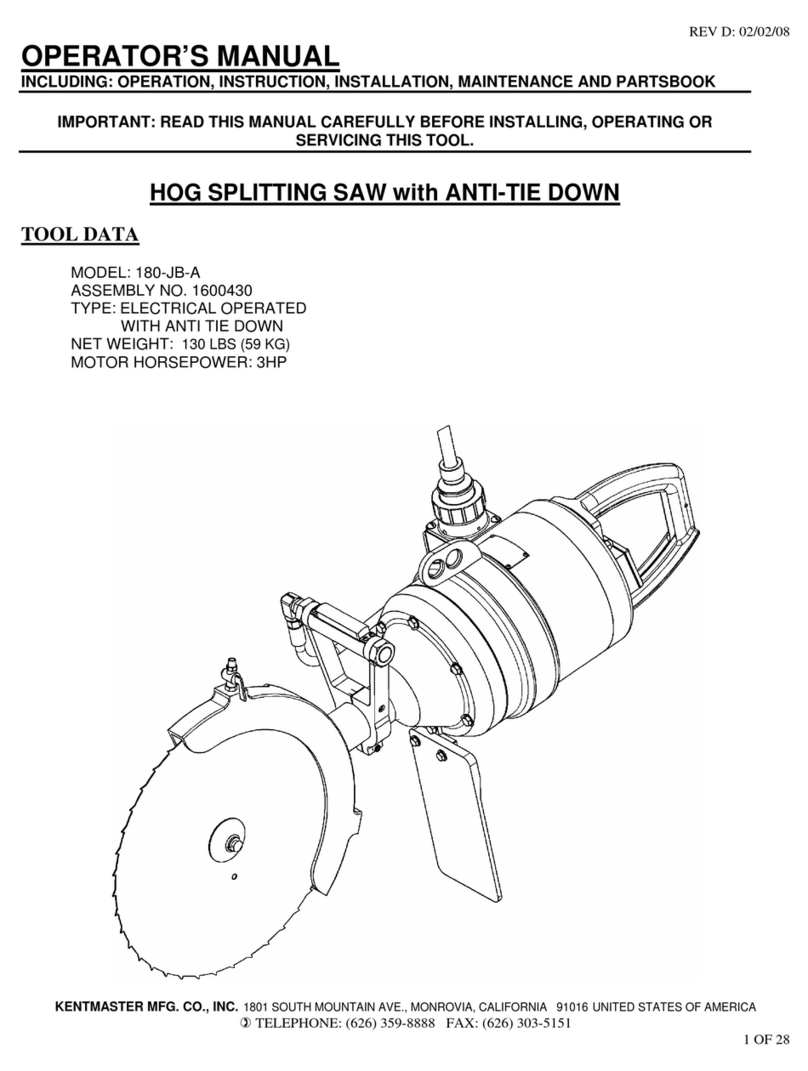

•IF TOOL HAS "ANTI TIE DOWN" OPTION, BOTH TRIGGERS MUST BE DEPRESSED SIMULTANEOUSLY FOR TOOL

TO ACTIVATE.

. TO PERFORM WORK, HOLD TOOL FIRMLY AT BOTH HANDLES. SQUEEZE TRIGGERS TO ACTIVATE TOOL.

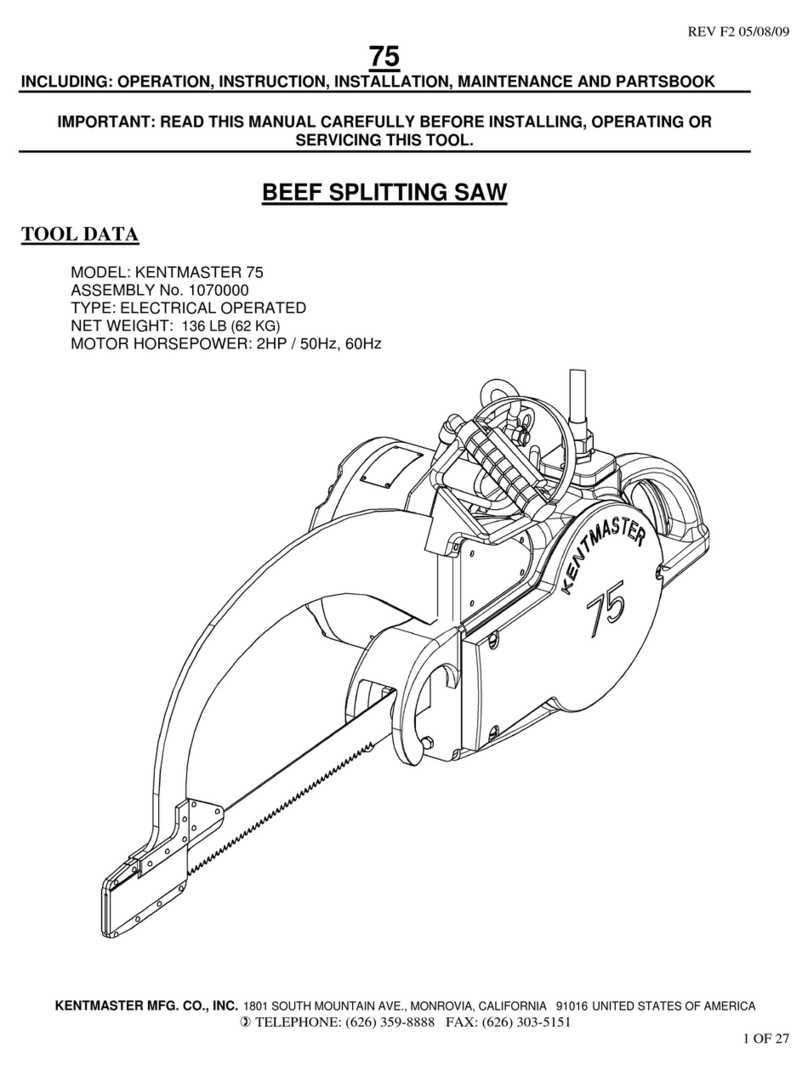

3. POSITION TOOL AND PERFORM CUTTING OPERATION. DESIGNED TO REMOVE HORN COMPLETELY WITH THE

ADJACENT SKULL SECTION.

4. CUTTING DEPTH 4 ½”.

5. ONE OPERATOR CAN HANDLE IN EXCESS OF 200 BEFF PER HOUR.

MAINTENANCE

ONLY TRAINED AND QUALIFIED PERSONNEL ARE TO PERFORM MAINTENANCE

AND SERVICE TO THIS TOOL.

THE COMPRESSED AIR DISTRIBUTION SYSTEM MUST BE LARGE ENOUGH TO SUPPLY AN ADEQUATE VOLUME OF CLEAN

AND DRY COMPRESSED AIR TO THE TOOL.

1. MAKE ALL NECESSARY LINE CONNECTIONS TO THE TOOL.

. AN AIR FILTER REGULATOR LUBRICATOR (PART NO. 7200030) MUST BE INSTALLED IN AIR SUPPLY FOR EACH

TOOL.

3. FILL LUBRICATOR WITH KENTMASTER AIR MIST OIL (PART NO. 7903050). SET DRIP RATE ACCORDING TO

INSTRUCTIONS SUPPLIED. TURN ADJUSTMENT ON SIGHT FEED DOME TO INCREASE/DECREASE OIL DELIVERY.

MONITOR THE DEVICE BEING LUBRICATED AND READJUST IF NEEDED.

4. TOOL REQUIRES GREASING AT START OF EACH SHIFT. GREASE FOUR (4) LOCATIONS USING KENTMASTER GREASE

GUN (PART NO. 4501470) AND GREASE (PART NO. 7903070).

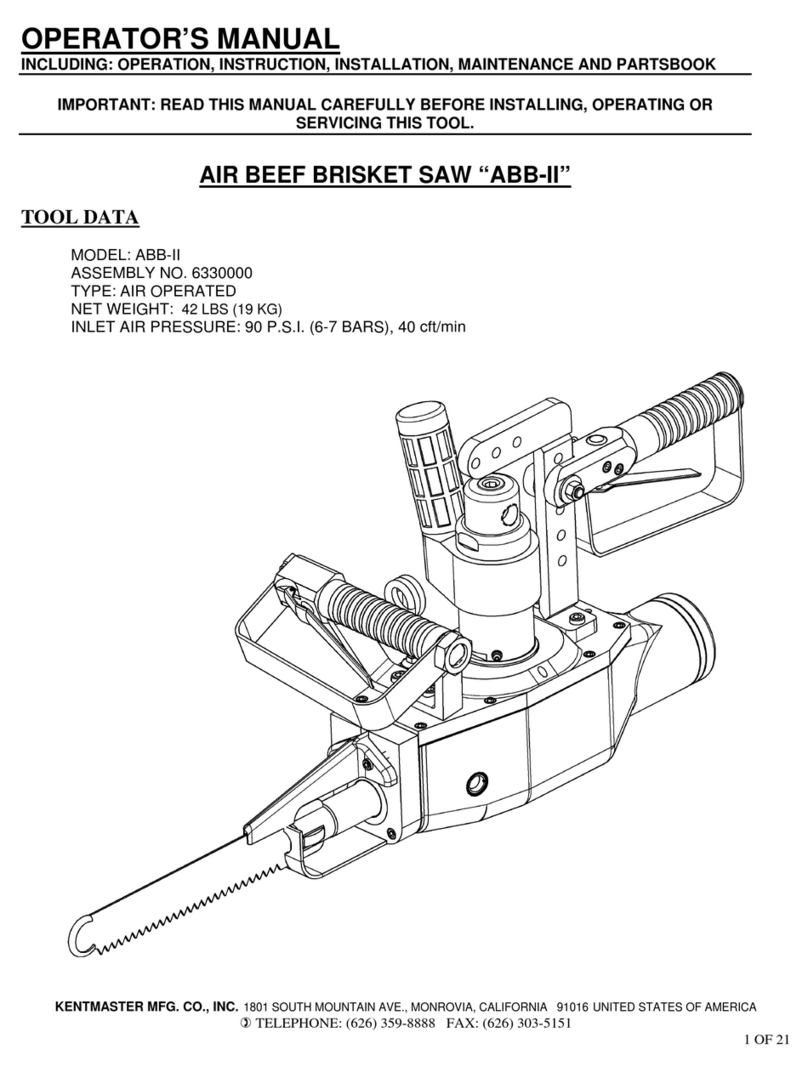

5. TOOL REQUIRES 40 S.C.F.M. OF AIR @ 90 P.S.I. AIR PRESSURE.

6. FLUSH AIR MOTOR AT END OF EACH DAY’S USE BY SQUIRTING A FEW SQUIRTS OF KENTMASTER AIR OIL MIST (PART

7903050) DIRECTLY INTO THE AIR INLET PORT. RUN TOOL A FEW SECONDS TO COAT AND PROTECT THE AIR MOTOR

AND INTERNAL PARTS OF TOOL.

BLADE REMOVAL AND CLEANING .

ALWAYS DISCONNECT POWER SUPPLY FROM TOOL BEFORE INSTALLING OR

REMOVING BLADE FROM TOOL.

ALWAYS WEAR WIRE MESH GLOVES WHEN INSTALLING OR REMOVING BLADE FROM TOOL.

1. USE WRENCH (ITEM NO. 3) TO REMOVE COLLAR (ITEM NO. 1, FIG. NO. 1).

. REMOVE BLADE (ITEM NO. 2, FIG. NO. 1).

3. CLEAN ALL PARTS REMOVED WITH SOAP AND WATER.

4. SHARPEN OR REPLACE BLADES WHEN NECESSARY.

5. REASSEMBLE IN REVERSE ORDER.

6. BLADE MAY BE STERILIZED WHILE IN MACHINE.

3 OF 20

! WARNING

! WARNING

! WARNING

! WARNING