BOP 5-20DL 020498 i

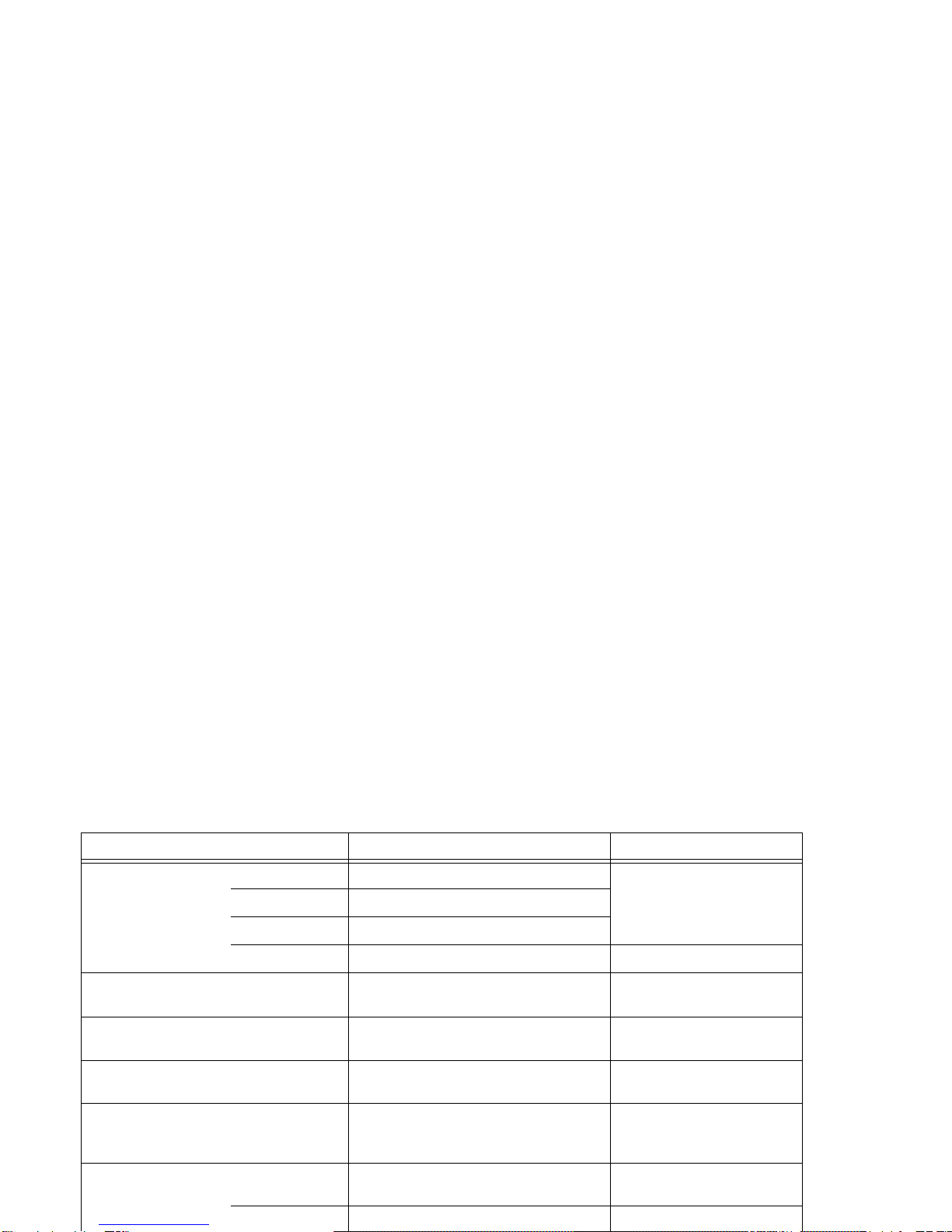

TABLE OF CONTENTS

SECTION PAGE

SECTION 1 - INTRODUCTION

1.1 Scope of Manual......................................................................................................................................... 1-1

1.2 General Description.................................................................................................................................... 1-1

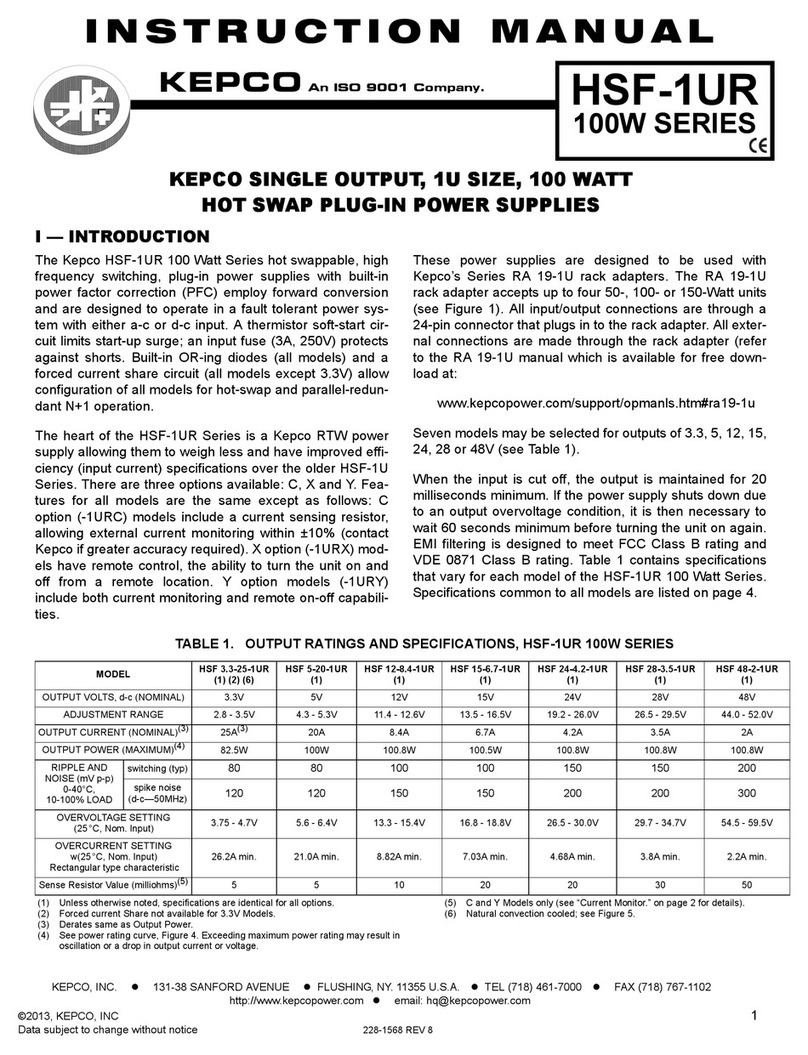

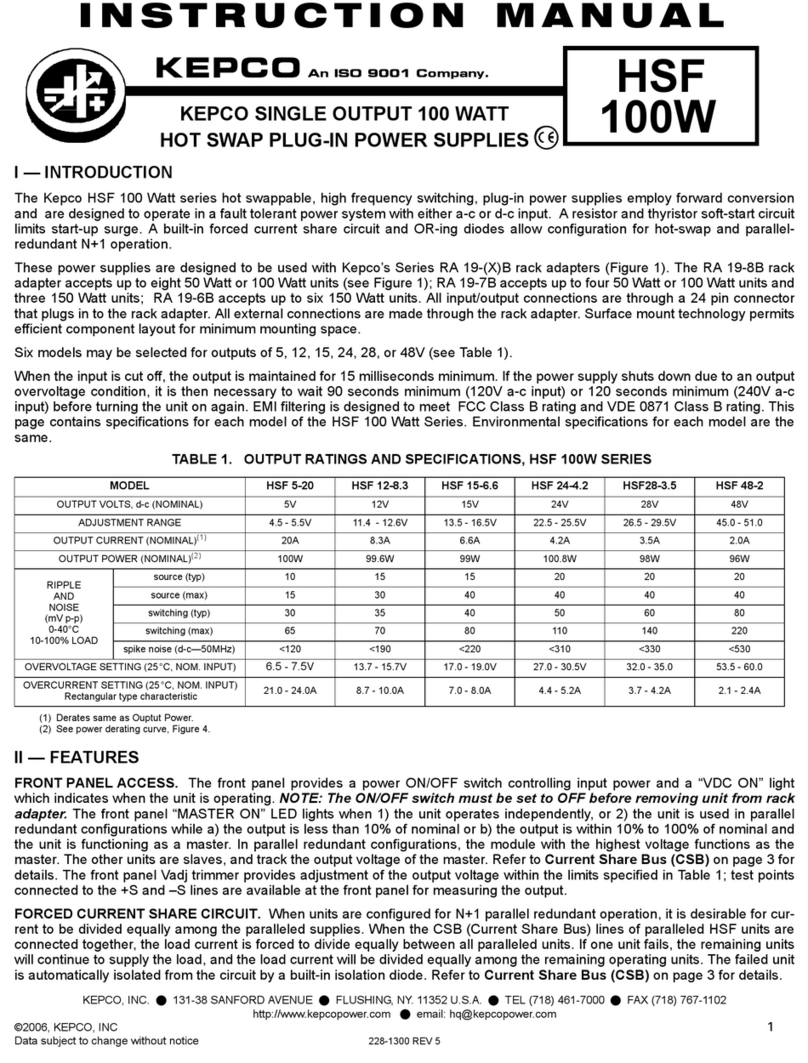

1.3 Electrical Specifications, General............................................................................................................... 1-1

1.3.1 Static Specifications................................................................................................................................ 1-5

1.3.2 Dynamic Specifications........................................................................................................................... 1-6

1.4 Miscellaneous Features.............................................................................................................................. 1-6

1.4.1 Output Range.......................................................................................................................................... 1-6

1.4.2 Rear Programming Features................................................................................................................... 1-7

1.4.3 Output ON-OFF Port............................................................................................................................... 1-8

1.4.4 Load Reactance...................................................................................................................................... 1-10

1.4.5 Remote Turn-off...................................................................................................................................... 1-10

1.4.6 Circuit Breaker Shutdown Prevention (at Power Loss) Circuit................................................................ 1-10

1.4.7 References.............................................................................................................................................. 1-10

1.4.8 Series Or Parallel Operation ................................................................................................................... 1-10

1.4.9 Voltage Control Channel......................................................................................................................... 1-11

1.4.10 Mode Switch............................................................................................................................................ 1-11

1.4.11 Current Control Channel ......................................................................................................................... 1-11

1.4.12 Bounding................................................................................................................................................. 1-11

1.4.13 Mode Lights............................................................................................................................................. 1-12

1.4.14 Remote Output ON-OFF LED................................................................................................................. 1-12

1.4.15 Standards................................................................................................................................................ 1-12

1.5 Mechanical Specifications .......................................................................................................................... 1-12

1.6 Equipment Supplied.................................................................................................................................... 1-12

1.7 Accessories ................................................................................................................................................ 1-13

1.8 Safety.......................................................................................................................................................... 1-13

SECTION 2 - INSTALLATION

2.1 Unpacking and Inspection. ......................................................................................................................... 2-1

2.2 Terminations, Controls and Indicators........................................................................................................ 2-1

2.3 A-C Input Requirements ............................................................................................................................. 2-3

2.4 Cooling........................................................................................................................................................ 2-3

2.5 Preliminary Checkout.................................................................................................................................. 2-4

2.6 Installation of Full-rack BOP Models........................................................................................................... 2-6

2.6.1 Slide Installation...................................................................................................................................... 2-6

2.7 Load Connection......................................................................................................................................... 2-7

2.7.1 Load Connection, Local Sensing............................................................................................................. 2-7

2.7.2 Load Connection, Remote Sensing......................................................................................................... 2-8

2.7.3 A-c Ground.............................................................................................................................................. 2-8

2.7.4 D-c Ground.............................................................................................................................................. 2-8

SECTION 3 - OPERATION

3.1 Introduction................................................................................................................................................. 3-1

3.2 Power Supply Basics.................................................................................................................................. 3-1

3.2.1 External Programming Resistors............................................................................................................. 3-3

3.2.2 Active Programming Sources.................................................................................................................. 3-3

3.2.3 External Leads ........................................................................................................................................ 3-3

3.2.4 External Voltage Monitor......................................................................................................................... 3-3

3.2.5 External Current Monitor......................................................................................................................... 3-4

3.3 Local (Front Panel) Output Control............................................................................................................. 3-4

3.3.1 Voltage Mode Operation with Current Limiting........................................................................................ 3-4

3.3.2 Local Control of Current Limiting............................................................................................................. 3-6

3.3.3 Current Mode Operation with Voltage Limiting........................................................................................ 3-6

3.3.4 Local Control of Voltage Limiting............................................................................................................. 3-8

3.4 Remote Control of Voltage Channel........................................................................................................... 3-9

3.4.1 Remote Voltage Control Using Resistance (Potentiometer) ................................................................... 3-9