INSTRUCTION MANUAL

KEPCO

KEPCO, INC. " 131-38 SANFORD AVENUE " FLUSHING, NY. 11352 U.S.A. " TEL (718) 461-7000 " FAX (718) 767-1102

http://www.kepcopower.com " email: hq@kepcopower.com

An ISO 9001 Company.

©2006, KEPCO, INC 1

Data subject to change without notice 228-1462 REV 5

HSF-1U

100W

KEPCO SINGLE OUTPUT, 1U, 100 WATT

HOT SWAP PLUG-IN POWER SUPPLIES

I — INTRODUCTION

The Kepco HSF-1U 100 Watt Series hot swappable, high frequency switching, plug-in power supplies employ forward conver-

sion and are designed to operate in a fault tolerant power system with either a-c or d-c input. A thermistor soft-start circuit limits

start-up surge. A built-in forced current share circuit and OR-ing diodes allow configuration for hot-swap and parallel-redundant

N+1 operation.

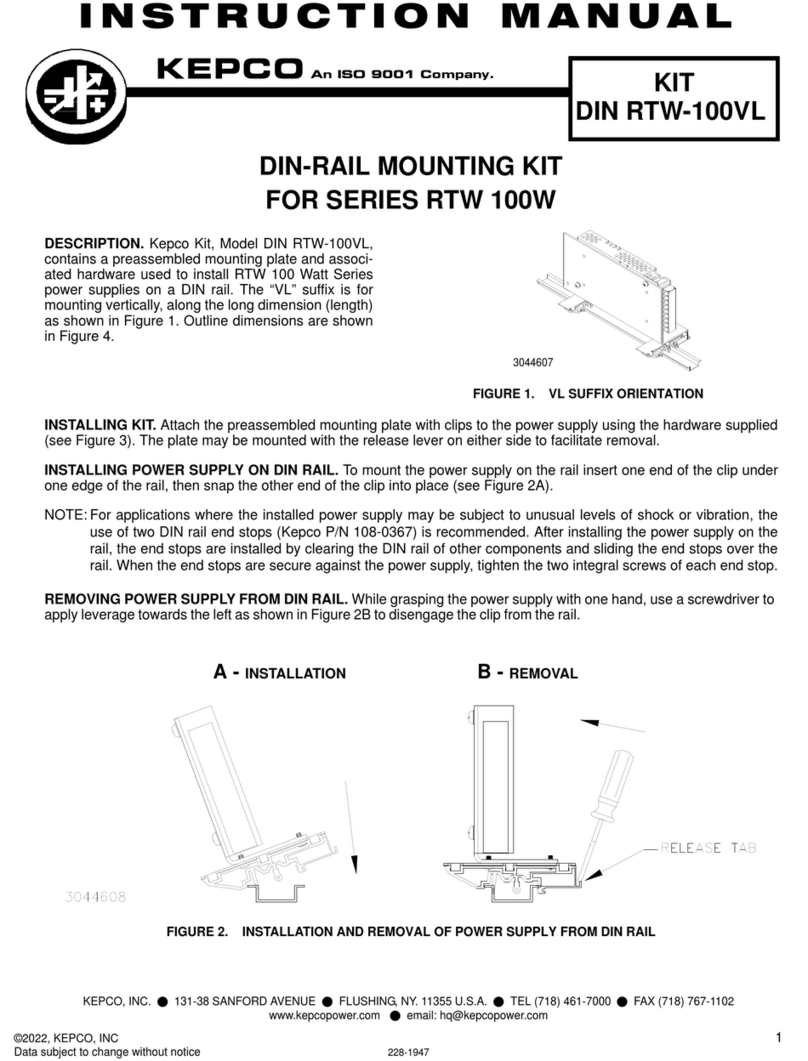

These power supplies are designed to be used with Kepco’s Series RA 19-1U rack adapters. The RA 19-1U rack adapter

accepts up to four 50 Watt or 100 Watt units (see Figure 1). All input/output connections are through a 24-pin connector that

plugs in to the rack adapter. All external connections are made through the rack adapter. Surface mount technology permits effi-

cient component layout for minimum mounting space.

Six models may be selected for outputs of 5, 12, 15, 24, 28, or 48V (see Table 1).

When the input is cut off, the output is maintained for 15 milliseconds minimum. If the power supply shuts down due to an output

overvoltage condition, it is then necessary to wait 60 seconds minimum before turning the unit on again. EMI filtering is designed

to meet FCC Class B rating and VDE 0871 Class B rating. This page contains specifications for each model of the HSF-1U 100

Watt Series. Environmental specifications for each model are the same.

II — FEATURES

FRONT PANEL ACCESS. The front panel provides a power ON/OFF switch controlling input power and a “VDC ON” light

which lights green when the unit is operating normally or red when the fan is inoperative and jumper J1 is installed (see III -

ALARMS). NOTE: The ON/OFF switch must be set to OFF before removing unit from rack adapter. The front panel “MAS-

TER ON” LED lights when 1) the unit operates independently, or 2) the unit is used in parallel redundant configurations while a)

the output is less than 10% of nominal or b) the output is within 10% to 100% of nominal and the unit is functioning as a master.

In parallel redundant configurations, the module with the highest voltage functions as the master. The other units are slaves, and

track the output voltage of the master. Refer to Current Share Bus (CSB) on page 3 for details. The front panel Vadj trimmer

provides adjustment of the output voltage within the limits specified in Table 1; test points connected to the +S and –S lines are

available at the front panel for measuring the output.

FORCED CURRENT SHARE CIRCUIT. When units are configured for N+1 parallel redundant operation, it is desirable for cur-

rent to be divided equally among the paralleled supplies. When the CSB (Current Share Bus) lines of paralleled HSF-1U units are

connected together, the load current is forced to divide equally between all paralleled units. If one unit fails, the remaining units

will continue to supply the load, and the load current will be divided equally among the remaining operating units. The failed unit

is automatically isolated from the circuit by a built-in isolation diode. Refer to Current Share Bus (CSB) on page 3 for details.

TABLE 1. OUTPUT RATINGS AND SPECIFICATIONS, HSF-1U 100W SERIES

MODEL HSF 5-20-1U HSF 12-8.3-1U HSF 15-6.6-1U HSF 24-4.2-1U HSF 28-3.5-1U HSF 48-2-1U

OUTPUT VOLTS, d-c (NOMINAL) 5.0V 12.0V 15.0V 24.0V 28.0 48.0

ADJUSTMENT RANGE 4.5 - 5.5V 11.4 - 12.6V 13.5 - 16.5V 22.5 - 25.5V 26.5 - 29.5V 45 - 51V

OUTPUT CURRENT (NOMINAL)(1)

(1) Derates same as Output Power.

20.0A 8.3A 6.6A 4.2A 3.5A 2.0A

OUTPUT POWER (NOMINAL)(2)

(2) See power derating curve, Figure 4.

100.0W 99.6W 99W 100.8W 96W 96W

RIPPLE

AND

NOISE

(mV p-p)

0-40°C

10-100% LOAD

source (typ) 10 15 15 25 30 30

source (max) 20 30 30 30 60 60

switching (typ) 30 35 40 50 60 80

switching (max) 65 70 80 110 140 220

spike noise (d-c—50MHz) 120 190 220 310 330 530

OVERVOLTAGE SETTING 25°C, NOM. INPUT 6.5 - 7.5V 13.7 - 15.7V 17.0 - 19.0V 27.0 - 30.5V 32.0 - 35.0 53.5 - 60.0

OVERCURRENT SETTING 25°C, NOM. INPUT

Rectangular type characteristic 21.0 - 24.0A 8.7 - 10.0A 7.0 - 8.0A 4.4 - 5.2A 3.7 - 4.2A 2.1 - 2.4A