HSM OPR 052912 i

TABLE OF CONTENTS

SECTION PAGE

SECTION 1 - INTRODUCTION

1.1 Scope of Manual ..................................................................................................................................... 1-1

1.2 General Description................................................................................................................................. 1-1

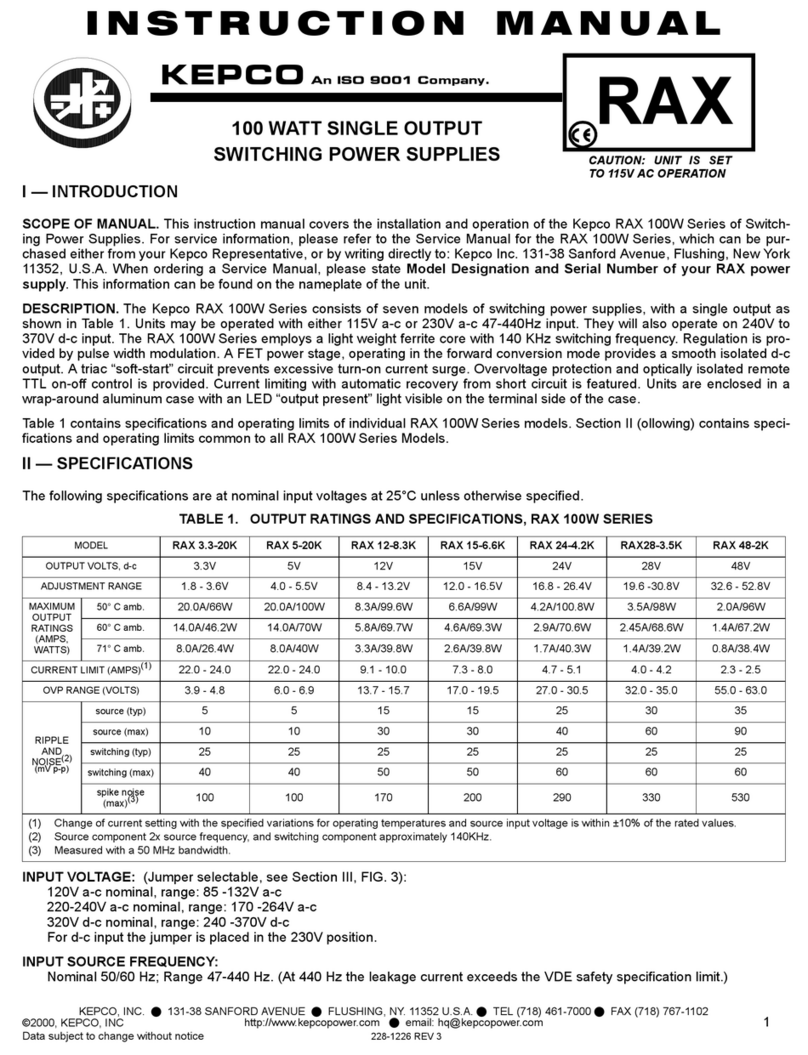

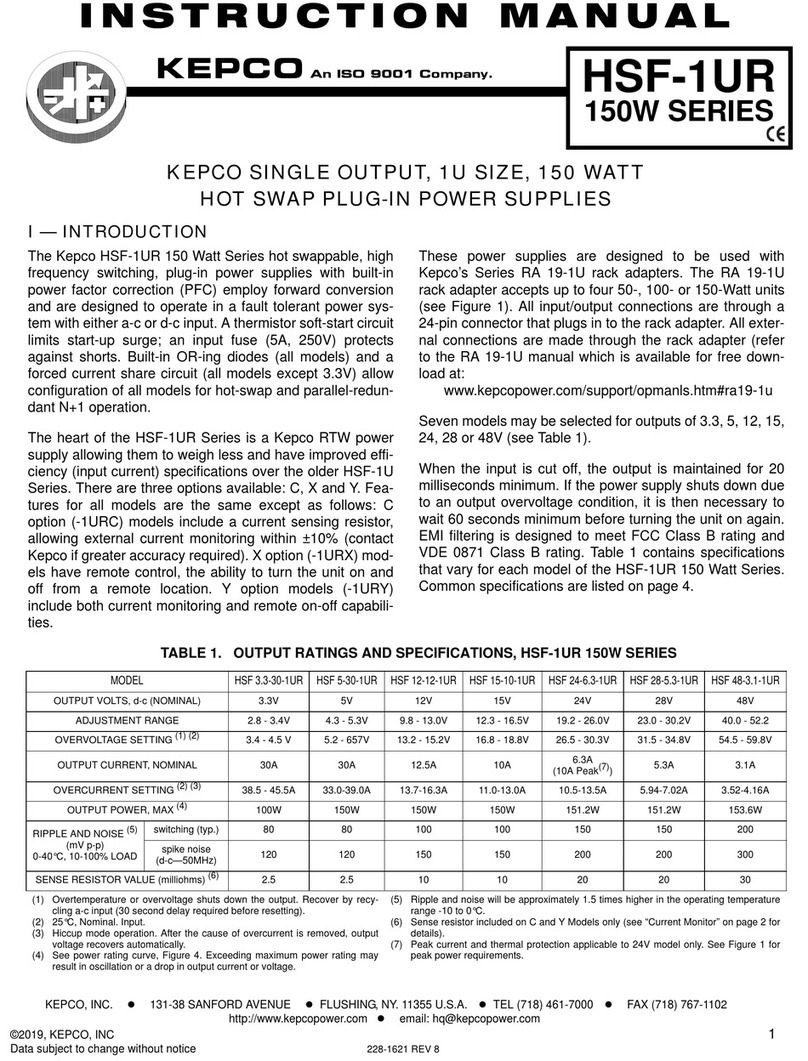

1.3 Specifications .......................................................................................................................................... 1-1

1.4 Miscellaneous Features .......................................................................................................................... 1-5

1.4.1 Control/programming......................................................................................................................... 1-5

1.4.2 Status Flags:...................................................................................................................................... 1-5

1.4.3 Setpoint Monitors:.............................................................................................................................. 1-5

1.4.4 Remote Error Sensing: ...................................................................................................................... 1-5

1.4.5 Load Sharing: .................................................................................................................................... 1-5

1.4.6 Load Monitor:..................................................................................................................................... 1-5

1.4.7 Auxiliary Supply: ................................................................................................................................ 1-5

1.4.8 Overcurrent/undervoltage Protection:................................................................................................ 1-5

1.4.9 Current Walk-in:................................................................................................................................. 1-5

1.4.10 Remote Reset:................................................................................................................................... 1-5

1.5 Options .................................................................................................................................................... 1-6

1.5.1 Battery Charger (B Suffix):................................................................................................................. 1-6

1.6 Accessories ............................................................................................................................................. 1-6

SECTION 2 - INSTALLATION

2.1 Unpacking and Inspection ....................................................................................................................... 2-1

2.2 Terminations and Controls ...................................................................................................................... 2-1

2.3 Source Power Requirements .................................................................................................................. 2-3

2.4 Cooling .................................................................................................................................................... 2-3

2.5 Preliminary Operational Check................................................................................................................ 2-3

2.6 Installation ............................................................................................................................................... 2-4

2.7 Wiring Instructions................................................................................................................................... 2-4

2.7.1 Safety Grounding............................................................................................................................... 2-4

2.7.2 Source Power Connections ............................................................................................................... 2-4

2.7.3 D-C Output Grounding....................................................................................................................... 2-5

2.7.4 Power Supply/Load Interface............................................................................................................. 2-5

2.7.5 Load Connection - General................................................................................................................ 2-6

2.7.5.1 Load Connection - Method I (Local Error Sensing)...................................................................... 2-7

2.7.5.2 Load Connection - Method II (Remote Error Sensing)................................................................. 2-8

2.7.5.3 Load Connection - Method III (Series Connection)...................................................................... 2-9

2.7.5.4 Load Connection - Method IV (Parallel/Redundant Operation) ................................................... 2-10

2.7.6 Load Sharing ..................................................................................................................................... 2-11

2.7.7 Signal Connections............................................................................................................................ 2-12

SECTION 3 - OPERATING INSTRUCTIONS

3.1 Operating Configuration .......................................................................................................................... 3-1

3.2 Remote Error Sense................................................................................................................................ 3-1

3.3 Output Voltage Programming.................................................................................................................. 3-1

3.4 Output Voltage Range............................................................................................................................. 3-2

3.5 Current Limit Programming ..................................................................................................................... 3-2

3.6 Current Limit Programming Range.......................................................................................................... 3-3

3.7 Setpoint Monitors .................................................................................................................................... 3-3

3.8 Overvoltage Protection Adjustment......................................................................................................... 3-4

3.9 Current Limit Characteristic..................................................................................................................... 3-5

3.10 Current Walk-in Circuit ............................................................................................................................ 3-6

3.11 5VAUX Floating Supply ........................................................................................................................... 3-6

3.12 Remote Inhibit/Remote Reset Controls................................................................................................... 3-7