FIGURE

3-18

LIST OF ILLUSTRATIONS (cont'd.)

Connections for

Illumination

Control,

Using the

EXT.

CURRENT

COMPARISON

AMPLIF-IER.

Multiple

Power Supply Fault Detection Loop

.......

.

PAGE

.

..........................

3-20

.

........................

3-21

3-20

Automatic

Series

Connections

..............................................

3-22

3-21

Developing the Drive for Master/Slave Series Connection,

ATE

Power Supplies

With

More Than 6

Volt

Output

Voltage

..........................

3-23

3-22 Master

Slave

Series Connection,

ATE

Power Supplies

With

> 6

Volt

Output

Voltage

.............................................

3-24

3-23 Developing the Driver

for

Master/Slave Series Connection,

for 6

Volt

ATE

Supplies

..................................................

3-25

3-24

"Automatic"

Parallel Operation,

Output

Graph

...................................

3-26

3-25 Connections

for

Automatic

Parallel Operation

...................................

3-27

3-27 Location

of

the Overvoltage Sensing

Lead

Disconnect

..............................

3-30

3-28 Redundant Parallel Connection

.............................................

3-31

3-29 Programming With Reference

to

the

NEGATIVE

Output

of

the

ATE

....................

3-32

3-30 Connections

for

Programming

With

Reference

to

the

NEGATIVE

Output

of

the

ATE.....

.

....................................

3-33

3-31

Isolated Flag Signal Outputs

...............................................

3-34

4-1

Crossover Characteristics,

ATE

Power Supply

...................................

.4-1

4-2 Voltage Comparison Equivalent

Circuit

. .

....................................

.4-1

4-3 Current Comparison Equivalent Circuit

.......................................

.4-2

4-4 Generation

of

the Internal Control Signal

for

the

ATE

Voltage

and

Current Channels

..........................................

.4-2

4-5 Generation

of

the Internal Crowbar Level Signal

.................................

.4-3

4-6

ATE

Simplified Schematic Diagram, General

Circuitry

...........................

4-7/4-8

4-7 Programmable Overvoltage Protector and Crowbar Circuit,

Simplified Schematic Diagram

...........................................

4-9/4-10

5-1

Disassembly

of

the

ATE

Power Supply

........................................

5-1

5-2 Test Set-up Diagrams

for

Output

Effect

Measurements

...........................

5-5/5-6

6-1

Component Location, Main

Chassis

Assembly With

Front

Panel

and Heat Sink Assembly

..............................................

6-17/6-18

6-2 Component Location, Control Assembly

...................................

6-19/6-20

6-3 Main Schematic Diagram

..............................................

6-21/6-22

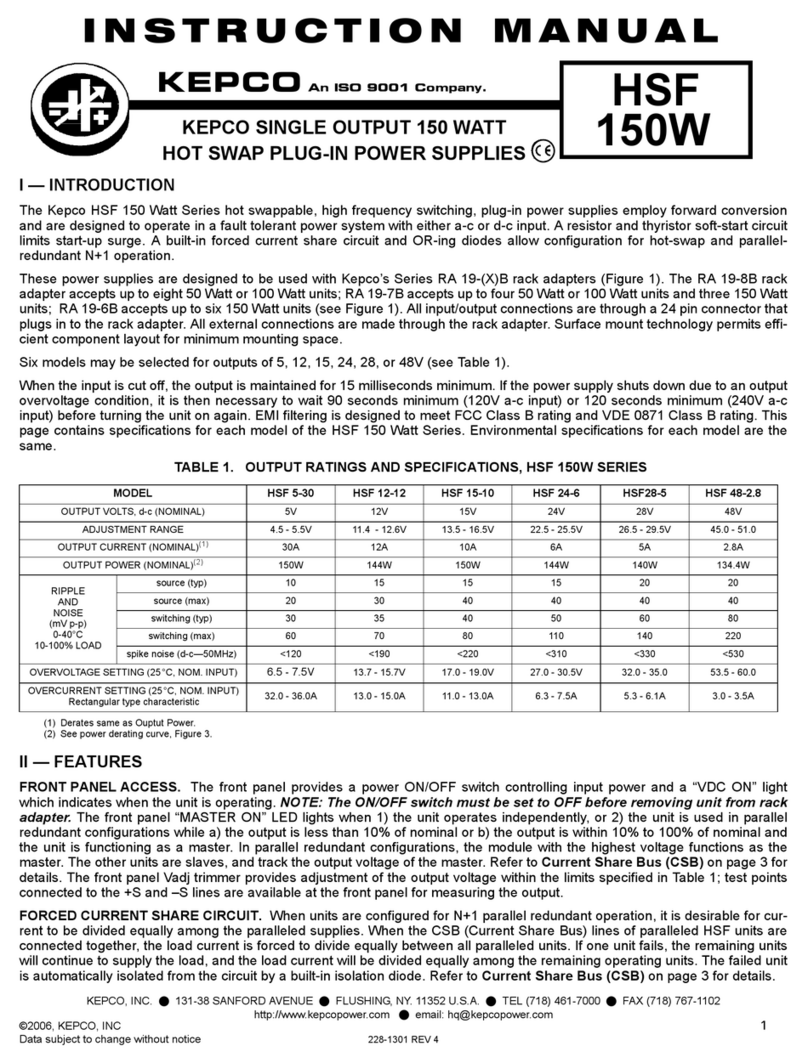

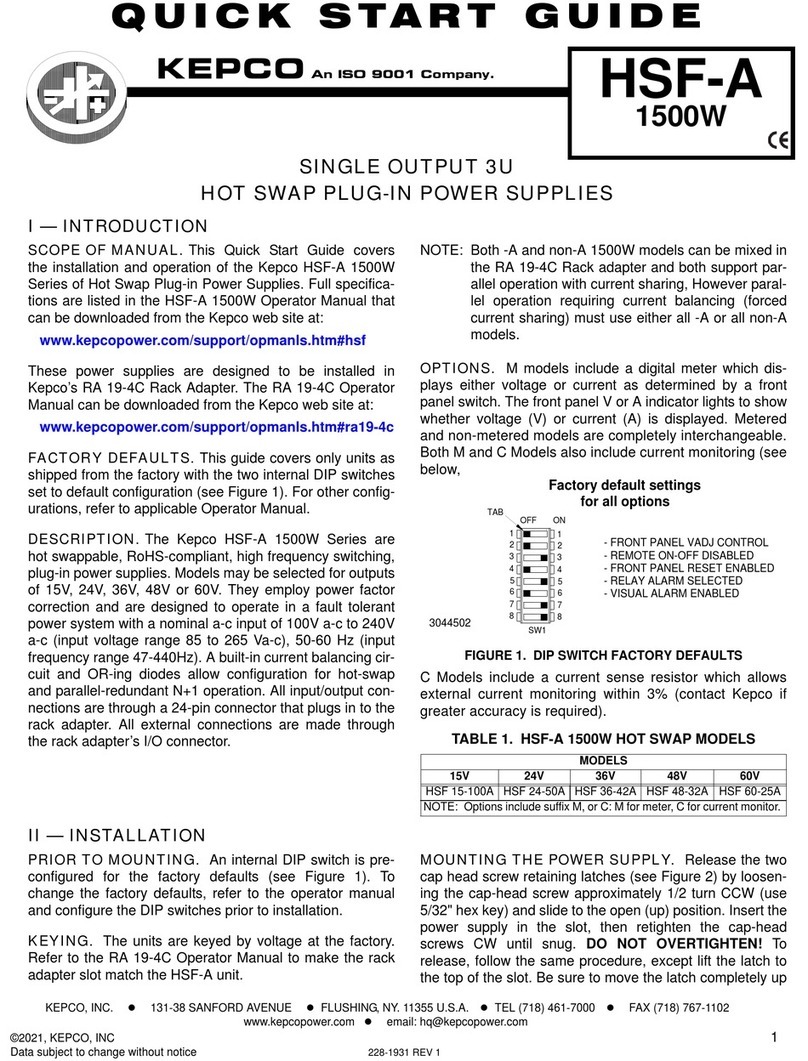

TABLE

1-1

1-2

2-1

2-2

2-3

ATE

l/4-2078

LIST OF TABLES

PAGE

D-C

Output

Ratings,

ATE

Power Supplies

......................................

1-2

Output

Effects, Offset Variations and Ripple Specifications

..........................

1-3

Internal Controls and Their Functions

.........................................

2-1

Controls and Terminations,

Front

Panel.

......................................

.2-2

Rear

Terminations

......................................................

2-3

-

iii/iv-