Caution

Supply Voltage Note: The 24 VDC output rom some controllers may not have enough current to power the

MMI8000.

Caution Wire

Routing

Wire lengths should be minimized (Maximum 1600’ (500 m) shielded, 1000’ (300 m)

unshielded).

Wires should be run in pairs with a neutral or common paired with a hot or

signal line.

I wiring is to be exposed to lightning or surges, use appropriate surge

suppression devices.

Keep AC, high energy, and rapidly switching DC wiring separate rom

signal wires.

Equip ungrounded DC supplies with a resistor and capacitor in parallel to earth ground. This

provides a path or static and high requency dissipation. Typical values to use are 1MOhm and

4700pF.

Connection To make a connection, strip about 3/8” o insulation o the end o the wire, turn the connector

screw counterclockwise until the gap is wide open, insert the wire all the way in, and turn the

screw clockwise until it’s tight.

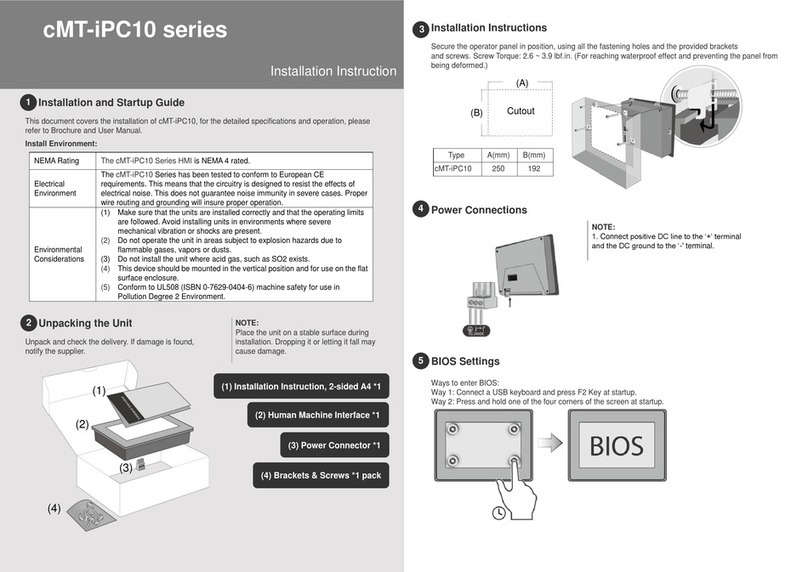

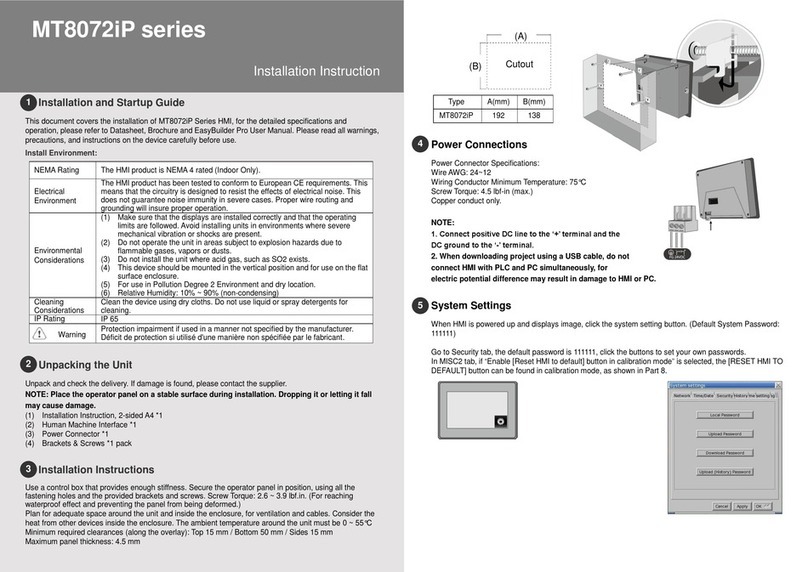

Connect positive DC line to the ‘+24V’ terminal and the DC ground to the

‘0V‘ terminal.

2.2.2 Grounding Requirements

Chassis ground must be used. DC ground is not directly coupled to Earth ground internally. It is

pre erable not to ground DC negative return to chassis ground as poor site earths can introduce

noise into a system, but i necessary an earth connection should be made, rom the power supply

return point to the central star earth point. Ground conductors should be as short and as large in

size as possible. The conductors must always be large enough to carry the maximum short circuit

current o the path being considered. Ground conductors should be connected to a tree rom a

central star earth ground point. This ensures that no ground conductor carries current rom any

other branch.

2.2.3 CE Requirements

To make an MMI8000 comply with EMC directives, and to reduce susceptibility to electrical

inter erence, a separate #14 AWG ground wire should be taken to the chassis ground terminal o the

power connector. This ground connection should be run directly to the central star earth connection

point (as recommended in most Installation Instructions).

2.2.4 Safety Guidelines

This section presents recommended installation practices, and procedures. Since no two

applications are identical, these recommendations should be considered as guidelines.

Hardware

Considerations

WARNING!

The system designer should be aware that devices in Controller systems could ail and thereby

create an unsa e condition. Furthermore, electrical inter erence in an operator inter ace, such as

an MMI8000, can lead to equipment start-up, which could result in property damage and/or

physical injury to the equipment operator.

I you, or your company, use any programmable control systems that require an operator or

attendant, you should be aware that this potential sa ety hazard exists and take appropriate

precautions. Although the speci ic design steps depend on your particular application, the

ollowing precautions generally apply to installation o solid-state programmable control devices.

In addition, these precautions con orm to the guidelines or installation o Controllers as

recommended in the NEMA ICS 3-304 Control Standards.

Programming

Considerations

To con orm with ICS Sa ety Recommendations, checks should be placed in the controller to

ensure that all writable registers that control critical parts o plant or machinery have limit checks