2 EWJ-BA-e-1917

GB

Version 1.7 2019-06

Operating manual

Contents

1Technical data................................................................................................ 4

2Appliance overview ....................................................................................... 7

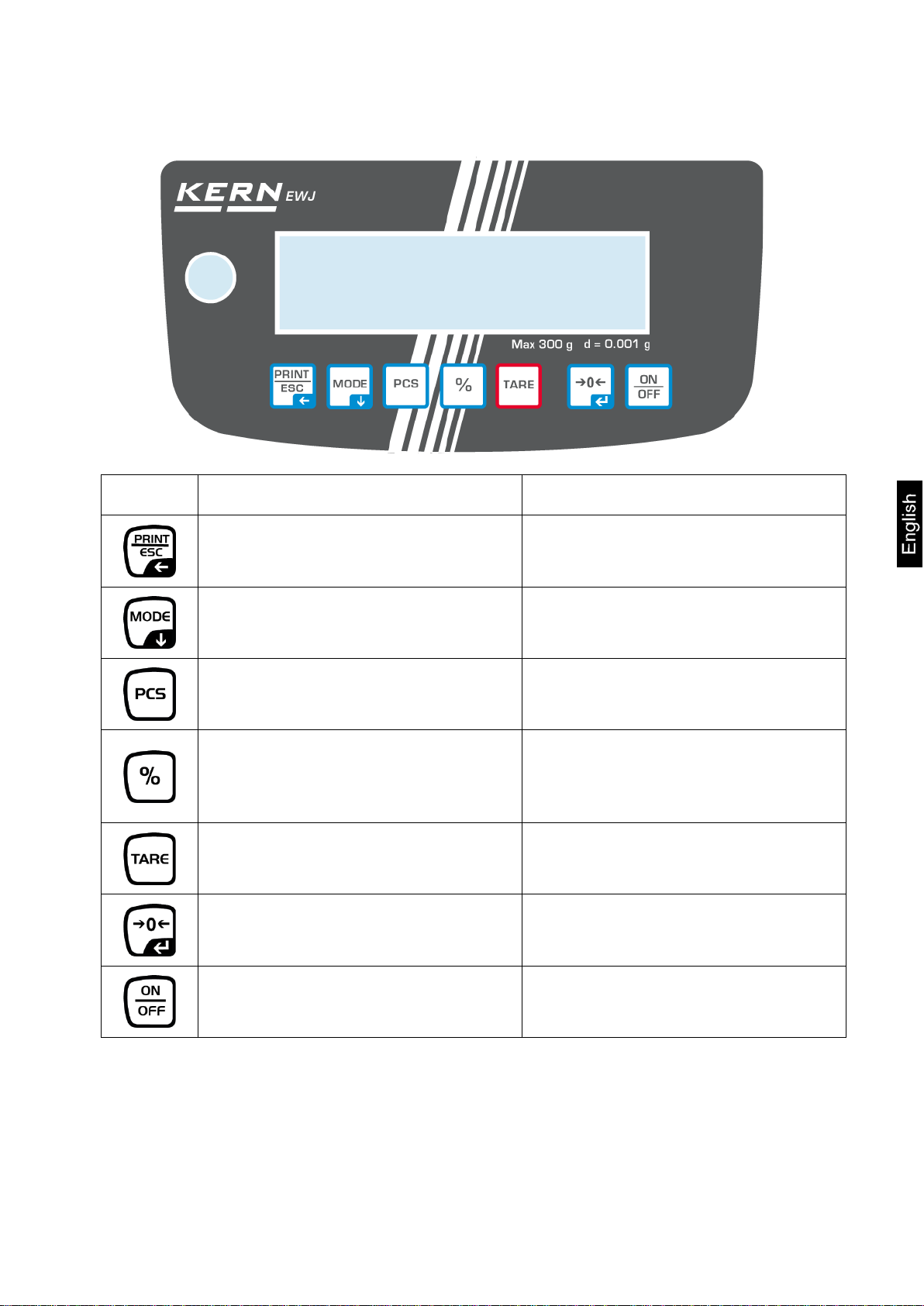

2.1 Keyboard overview..................................................................................................................... 9

2.2 Overview of display .................................................................................................................. 10

3Basic Information (General)........................................................................ 11

3.1 Proper use................................................................................................................................ 11

3.2 Improper Use............................................................................................................................ 11

3.3 Warranty................................................................................................................................... 11

3.4 Monitoring of Test Resources................................................................................................... 12

4Basic Safety Precautions............................................................................ 12

4.1 Pay attention to the instructions in the Operation Manual........................................................ 12

4.2 Personnel training..................................................................................................................... 12

5Transport and storage................................................................................. 12

5.1 Testing upon acceptance ......................................................................................................... 12

5.2 Packaging / return transport..................................................................................................... 12

6Unpacking, Setup and Commissioning ..................................................... 13

6.1Installation Site, Location of Use.............................................................................................. 13

6.2 Unpacking, Scope of delivery................................................................................................... 13

6.2.1 Scope of delivery / serial accessories: ..................................................................................... 13

6.2.2 Installing / removing transport fittings....................................................................................... 14

6.3 Mains connection...................................................................................................................... 18

6.4 Storage battery operation (optional)......................................................................................... 18

6.5 Connection of peripheral devices............................................................................................. 18

6.6Initial Commissioning................................................................................................................ 18

6.7 Adjustment................................................................................................................................ 19

6.7.1 Manual internal adjustment by pressing button........................................................................ 19

6.7.2 Automatic internal adjustment.................................................................................................. 20

6.8 Verification................................................................................................................................ 21

7Operation...................................................................................................... 22

7.1 Start-up..................................................................................................................................... 22

7.2 Switching Off ............................................................................................................................ 22

7.3 Zeroing...................................................................................................................................... 22

7.6 Percent determination .............................................................................................................. 23

7.7 Parts counting........................................................................................................................... 24

7.8 Manual totalizing....................................................................................................................... 25

7.9 Automatic adding-up................................................................................................................. 28

8Menu ............................................................................................................. 30

8.1 Navigation in the menu............................................................................................................. 30

8.2 Access to technology menu...................................................................................................... 31

8.3 Overview................................................................................................................................... 32

9Interfaces...................................................................................................... 35

9.1 Technical data .......................................................................................................................... 35

9.2 Printer operation (RS 232)........................................................................................................ 36

9.3 Output log (continuous output)................................................................................................. 37