MD15-HE, MD15-R-HE

Product Description Q

Page 3 / 14 3.09-20.125-01-EN | 2019-08-19

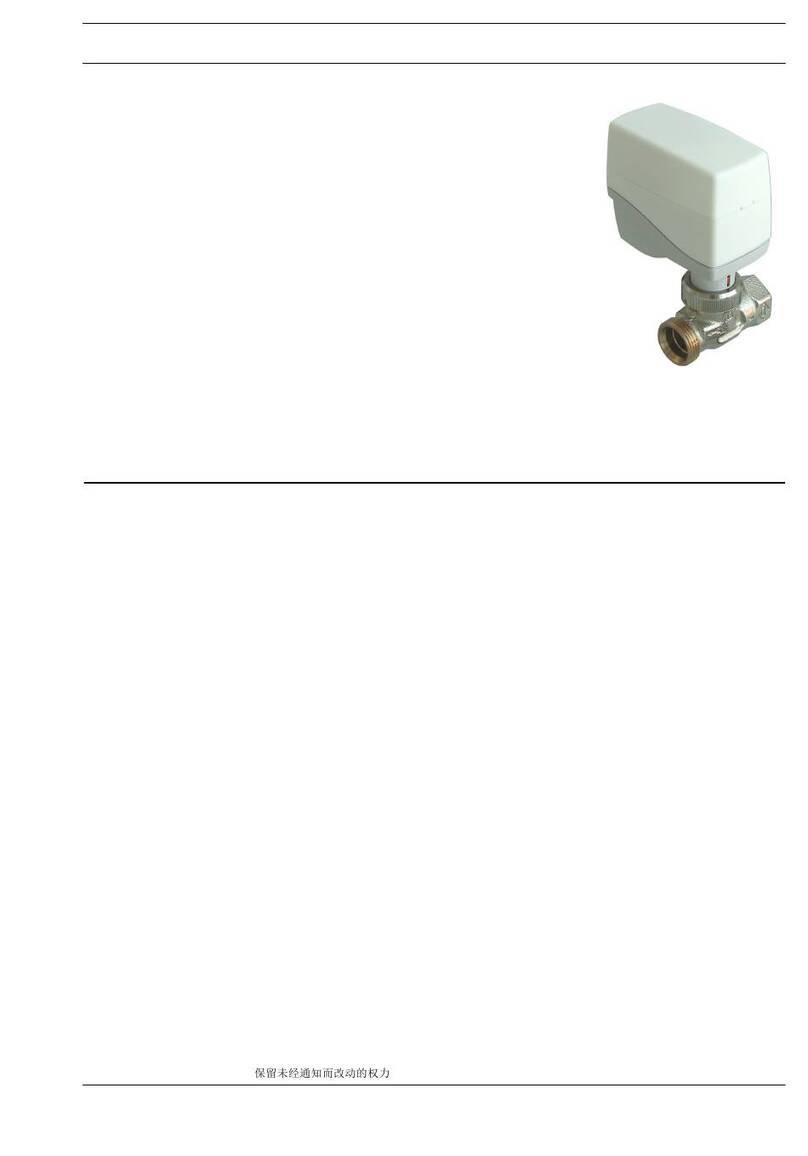

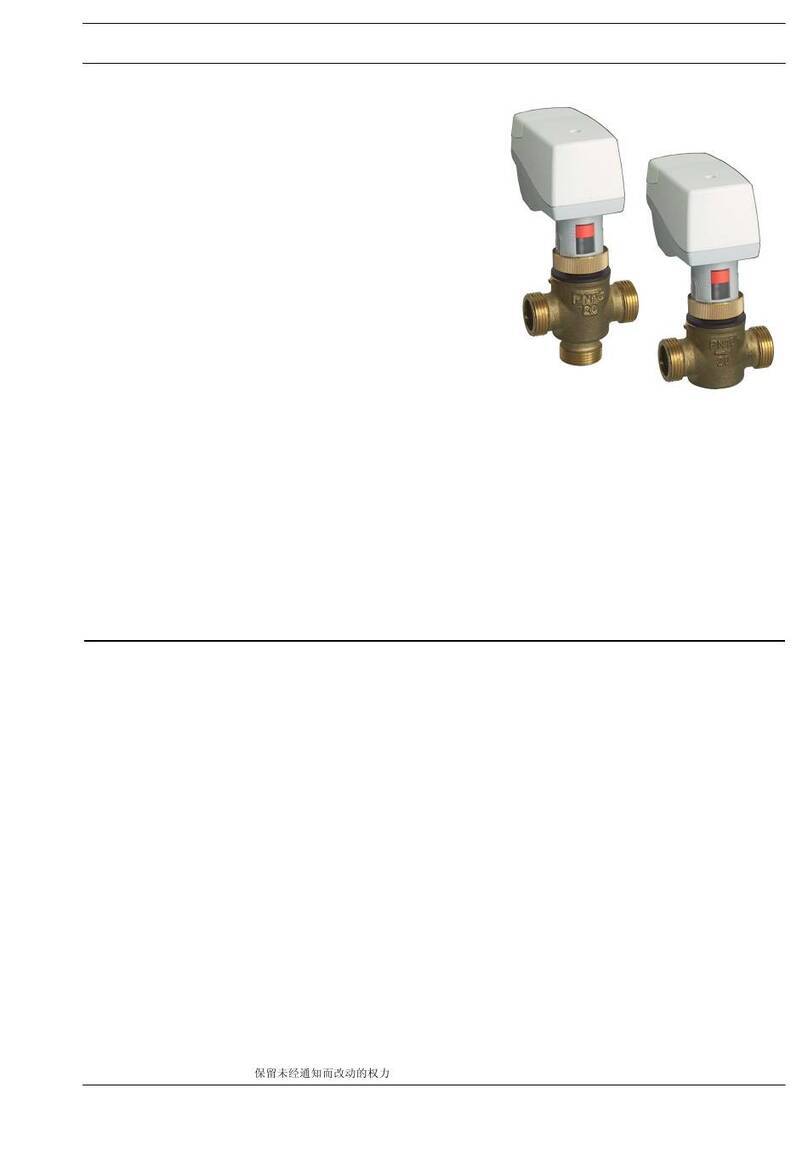

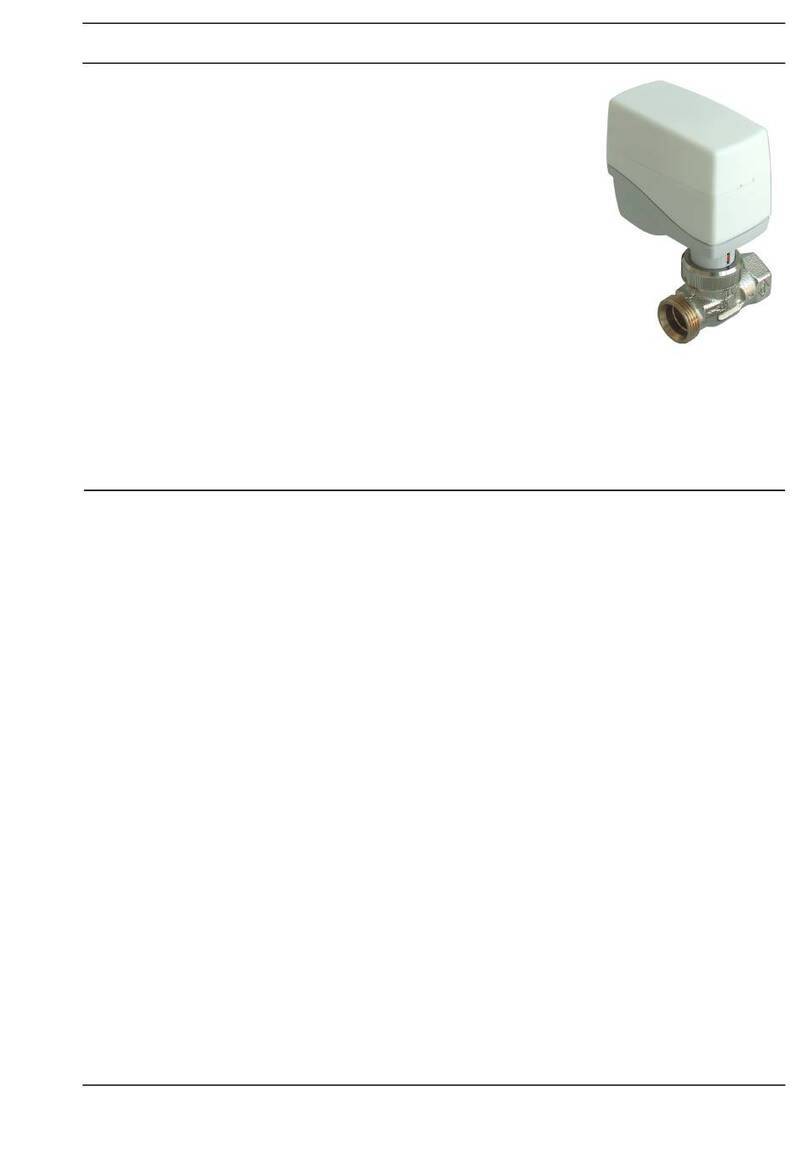

MD15-HE and MD15-R-HE small actuators

Technical Data

Accessories (not included in delivery)

MD15-HE Small actuator for Rxx and RWxx valves and

other valves with an M30x1.5 connection that

were manufactured by Heimeier, Honey-

well-MNG, Junkers, Honeywell-Baukmann,

Oventrop (2001 and later) or Cazzaniga

MD15-R-HE Same as MD15-HE, but with positioning feed-

back

Nominal voltage AC 24 V ± 10%; 50/60 Hz; 2.5 VA; DC 24 V ± 10%

Power consumption Dimensioning: 3.7 VA (AC 24 V); 1.7 W (DC 24 V)

Nominal: 2.5 VA (AC 24 V); 1.3 W (DC 24 V)

Switch-on current Max. 10 A for a short time

Control Or continuous control DC 0(2)..10 V; < 0.5 mA, invertible

Connection Built-in cable

MD15-HE: 1.5 m; 3 x 0.5 mm2

MD15-R-HE: 1.5 m; 5 x 0.5 mm2

Motor switch-off Actuator spindle: when extending = load-dependent, when retracting =

path-dependent

Display LED display for operating voltage

Actuating noise < 28 dB (A)

Positioning stroke 3 mm

Positioning time 22 s/mm

Positioning force 100 N (nominal)

Position indicator Stroke range scale

Position feedback Only with MD15-R-HE DC 0..10 V, 5 mA for 0..100% nominal stroke

Manual adjustment Only when disconnected from the power supply

Socket for hexagon key under the rubber pad on the actuator cover, 4 mm

key socket

Valve exercise Can be switched on

Ambient temperature 0..50 °C

Degree of protection IP54, only when installed in appropriate position (see p. 9)

Ambient humidity During operation: 0..85% r.h., non-condensing

Out of operation: 0..85% r.h., non-condensing

Overvoltage category III

Level of contamination 2

Protection class III in accordance with EN 60730

Installation position 360°

Maintenance Maintenance-free

Weight 250 g

VS3 Anti-vandalism protector for MD15-xx-HE