CONTENTS

CHECK BEFORE OPERATION…………………………..………………………1

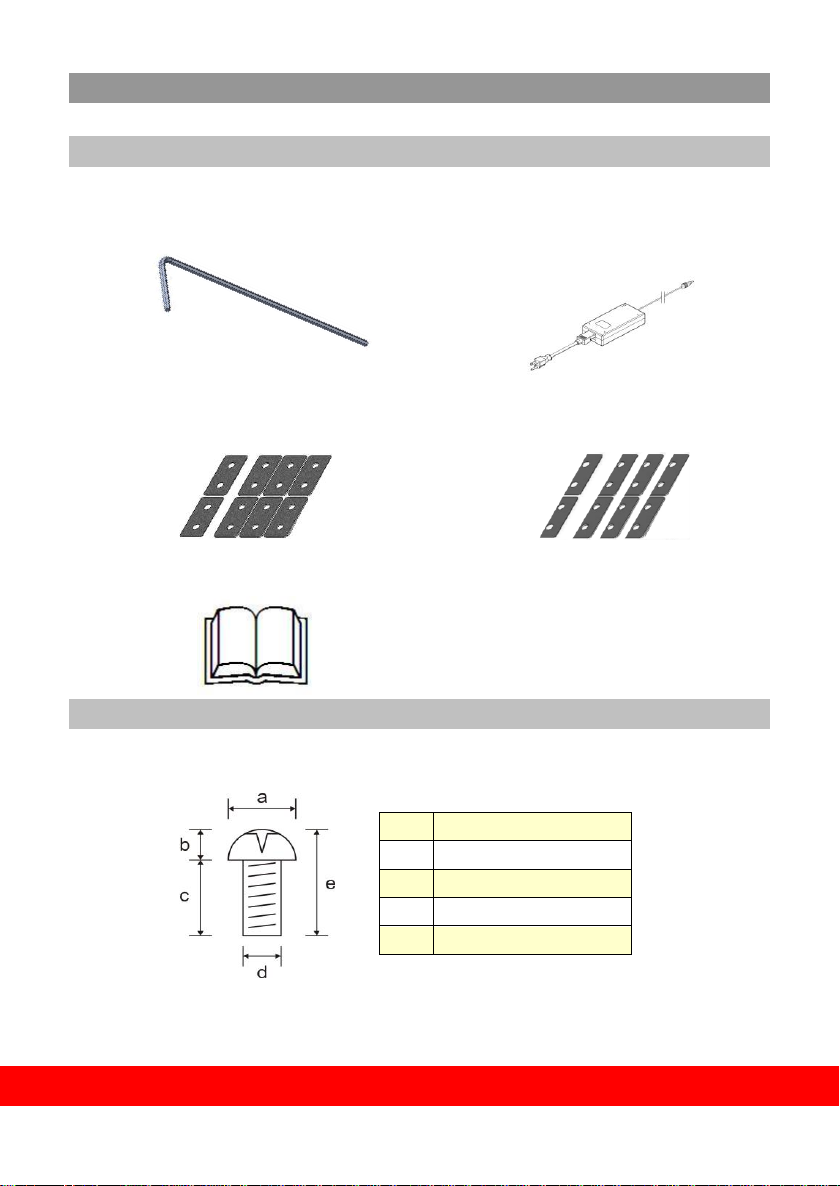

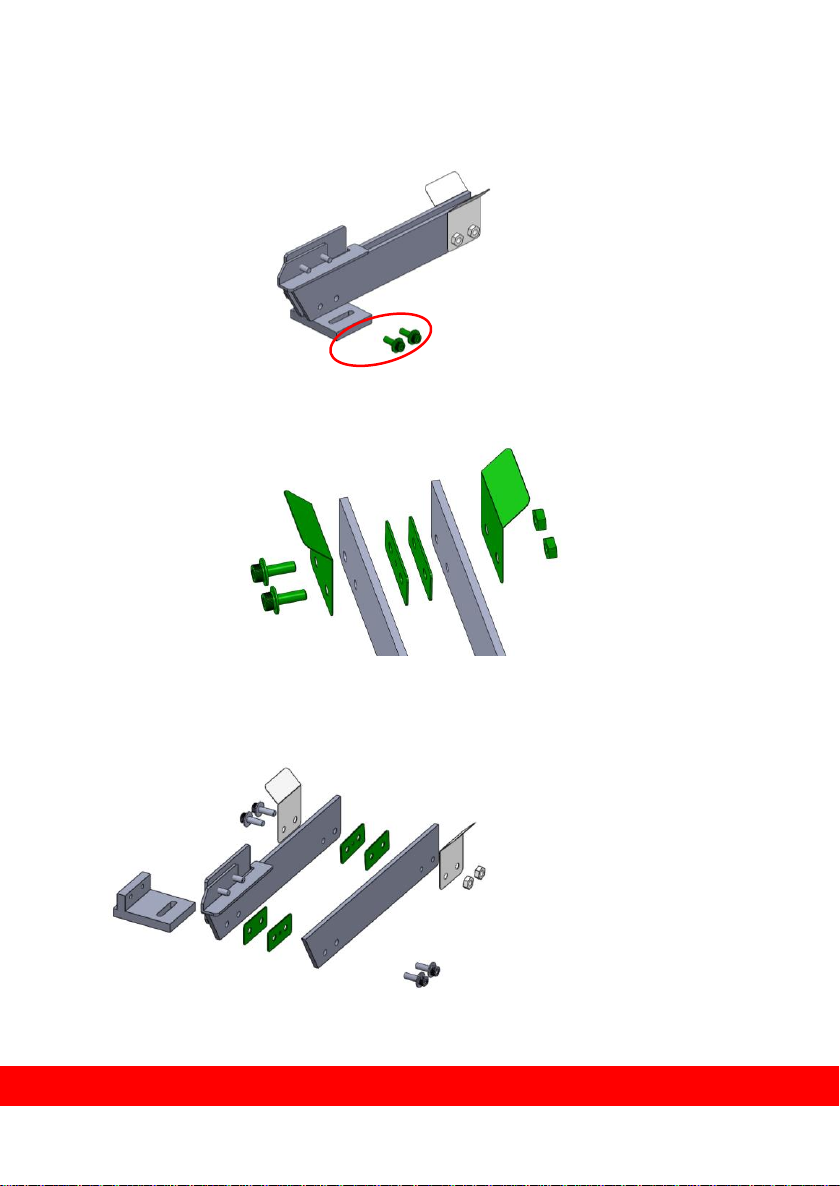

ACCESSORIES INCLUDED…………………………………………………….1

CHECK THE SCREW SIZE………………………..……………………..…1

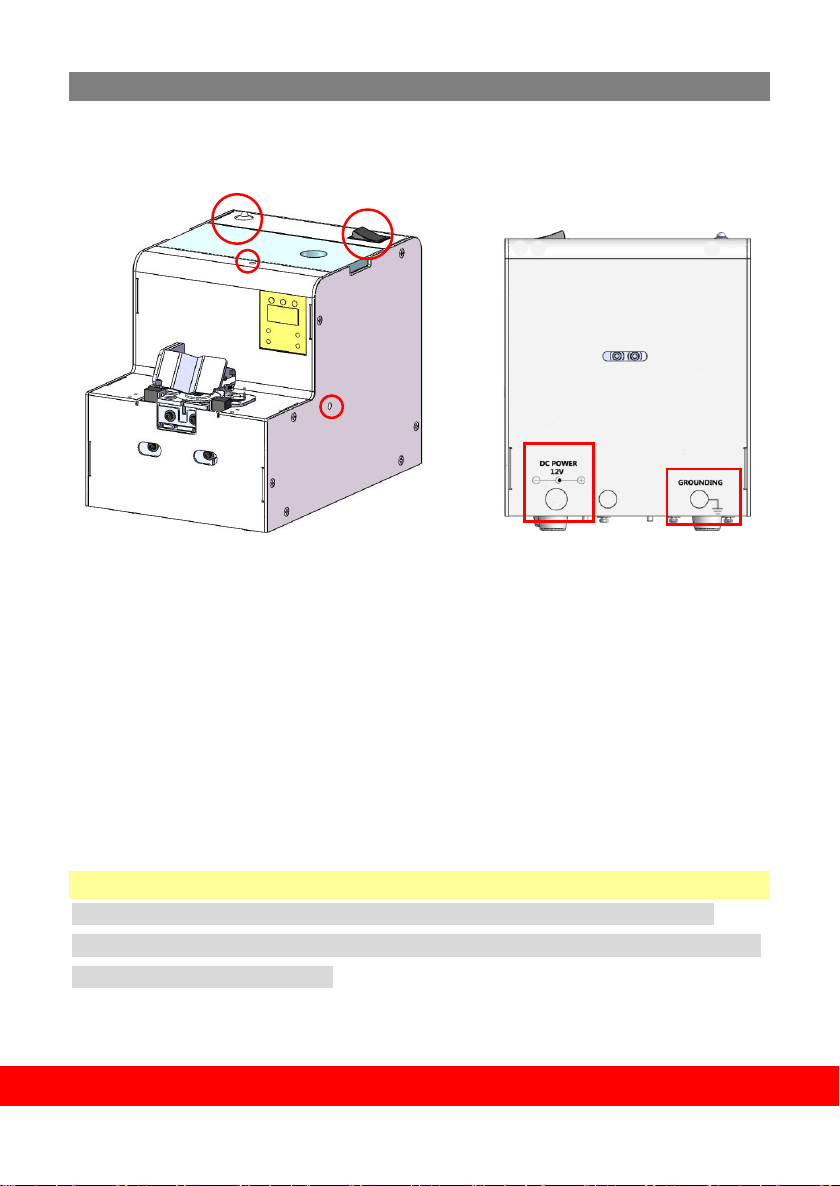

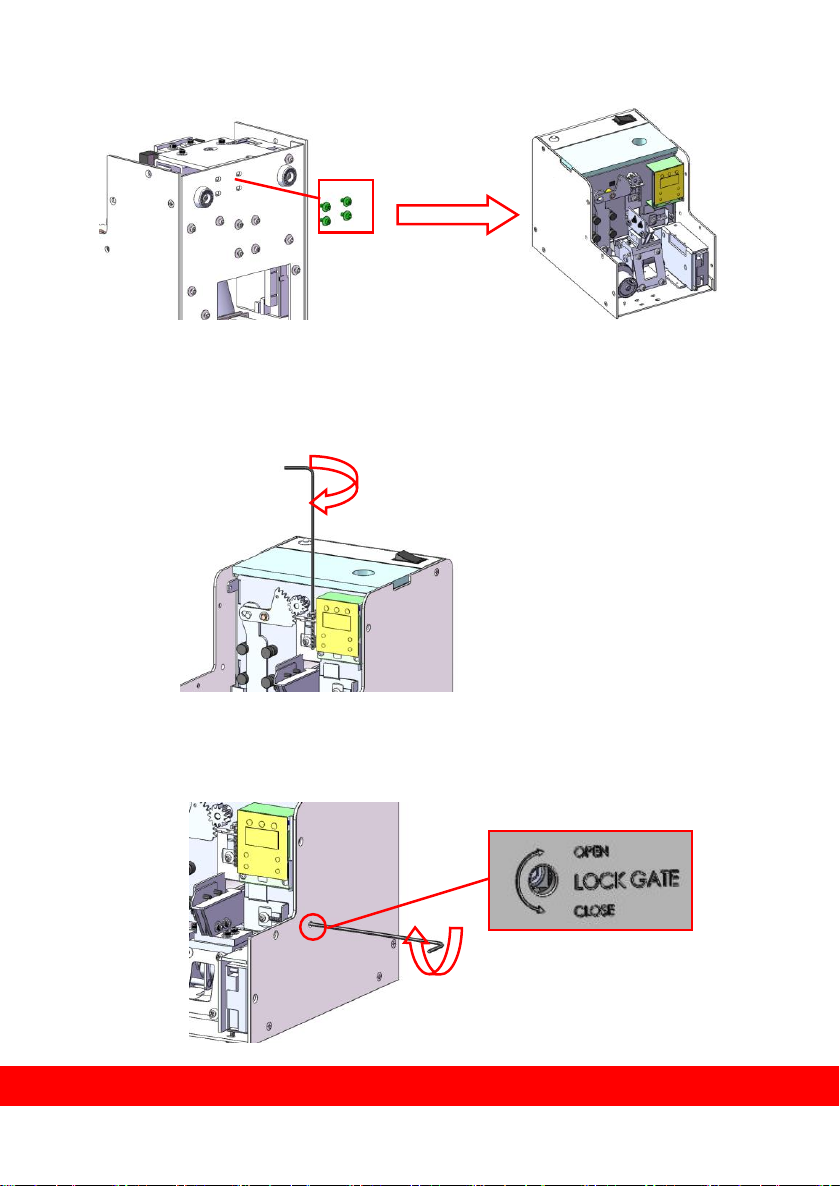

FUNCTIONS WITH ADJUSTING HOLES ON HOUSING AND PCB ……... .2

ADJUSTMENT………………………………………………………………………3

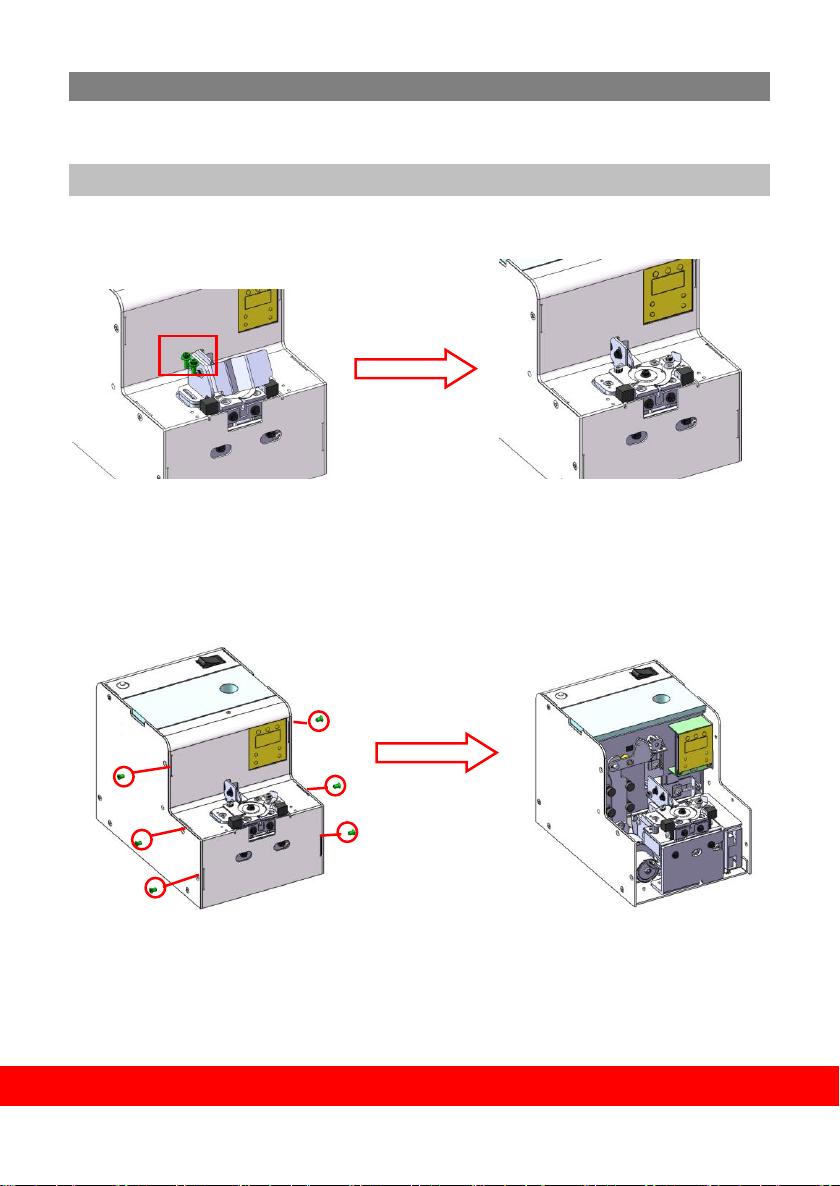

ADJUST THE RAIL ASSEMBLY…………………………………………………3

DISMANTLE THE RAIL ASSEMBLY………………………………………….3

ADJUST THE WIDTH OF RAIL ASSMEBLY…………………………………6

INSERT THE RAIL ASSEMBLY……………………………………………….8

ADJUST THE HOLDING PLATE……………………………………………….10

ADJUST THE FEEDING STRUCTURE……………………………………….11

ADJSUT THE SENSOR FUNCTION…………………………………………..13

ADJUST THE V CHASE ON ROLLER......……………………………………14

ADJUST THE BRUSH…………………………………………………………..15

OPERATION METHOD……………………………………………………………16

LOAD SCREWS INTO CHAMBER…………………………………………….16

PICKING UP SCREW…………………………………………………………...17

COUNTER INTERFACE OPERATION………………………………………18~20.

MAINTENANCE & TROUBLE SHOOTING……………………………….……21

MAINTENANCE & CLEANING…………………………………………………..22

INTERNATIONAL WARRANTY CONDITIONS………………………………...23~24