Page 4 Kim Lighting • 16555 E. Gale Ave. • P.O. Box 60080 • City of Industry, CA 91716-0080 • 626/968-5666 • FAX 626/330-3861

KIM LIGHTING LIMITED WARRANTY

When installed in accordance with Kim Installation Instructions and

accepted trade practices, the following shall apply:

General Product Limited Warranty Coverage

All material and component parts used in the manufacture of Kim

Products, are warranted to be free from defects of material and/or

workmanship for a period of 1 year from date of sale, with the following

exceptions:

Auxiliary Equipment

All auxiliary equipment (such as lamps, ballasts, and transformers)

provided by and/or included in Kim Products shall carry the component

manufacturer's warranty.

Copper, Bronze and Brass Landscape Components

Copper and Bronze Landscape fixture components shall be warranted

against defects of material and/or workmanship, and failure due to

corrosion, for a period of 25 years from date of sale.

Kim Lighting's brass components are constructed from several brass

parts that are manufactured by various methods at various times. Since

brass naturally deepens in color as it ages through the normal oxidation

process, these parts may exhibit subtle differences in coloration when the

product is new. This is normal and expected. These color differences will

be eliminated shortly after installation through the normal brass oxidation

process..

Composite In-Grade Components

Composite In-Grade fixture components installed below grade, shall be

warranted against defects of material and/or workmanship, and failure

due to corrosion, for a period of 7 years from date of sale.

Aluminum Landscape Components

Aluminum Landscape fixture components not in direct contact with soil,

shall be warranted against defects of material and/or workmanship for a

period of 3 years from date of sale. Aluminum fixture components in

direct contact with soil shall be warranted from defects of material and

failure from corrosion for a period of 1 year from date of sale.

Stainless Steel Components

Stainless steel landscape components (Lens Rings) installed in the

outdoor environment shall show signs of oxidation after 5 to 6 years of

install and is dependent on the application and its environment. A proper

maintenance and cleaning program will extend the beauty of the stainless

steel.

Limit of Liability and General Conditions

Only products which are installed, used and maintained in accordance

with applicable Kim instructions, specifications and accepted trade

practices, are covered by the Kim Warranty. During the warranty period,

with proof of purchase, Kim will repair or replace with the same or similar

product, at Kim's option, without charge. Labor costs are the owner's

responsibility and are excluded from this warranty. This warranty is void

if the product is modified, tampered with, misapplied, poorly installed,

improperly maintained, or subjected to abnormal conditions.

Repair or replacement as provided under this warranty is the exclusive

remedy of the purchaser. This warranty is in lieu of all other warranties,

expressed or implied, including any implied warranty of fitness for a

particular application. Kim Lighting shall not be liable to the purchaser

for indirect or consequential damages.

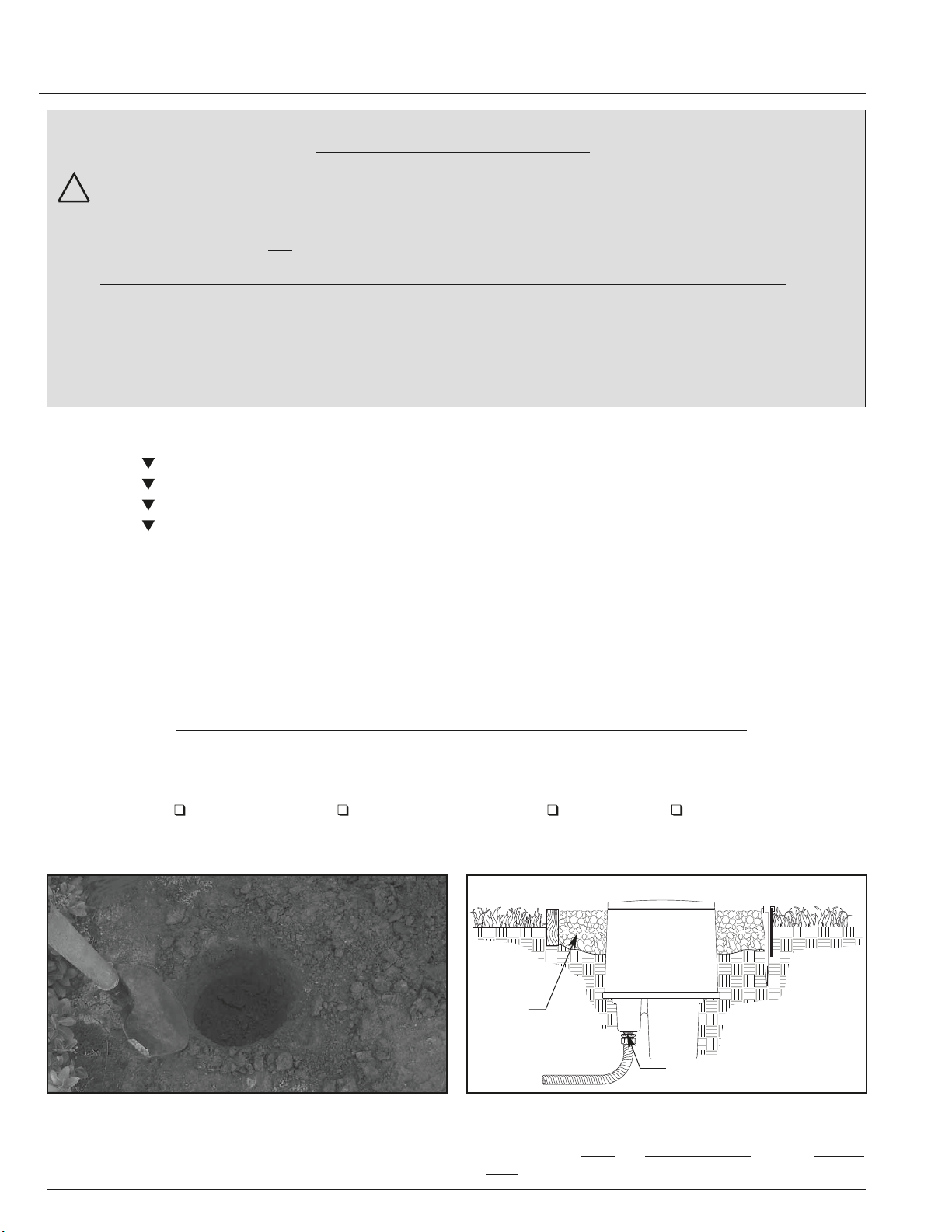

Lightvault®- LTV10, 20, 30 & 40 Series Installation Instructions

How may we serve you better?

Please let us know. Visit our website at:

www.kimlighting.com

Your input is valuable to us.

8. Replace splice compartment cover and

torque screws to 30-40 in./lbs. Place

dessicant package inside housing before

connecting quick disconnect.

9. Re-install rough-in debris shield and tighten

screws snuggly to prevent dirt and water

entry. Fixture is now ready for reflector and

lens installation. Make sure all surfaces

are completely clean before installing

covers and lens rings. Any foreign objects

trapped in the gasket areas will create

potential points of entry for ground water.

Rough-In Section cont'd.

Dessicant