KITO N6 Series User manual

OM-N6CEOZ-MGE-01

OWNER’S (OPERATOR’S) MANUAL AND

SAFETY INSTRUCTIONS

FOR KITO URETHANE WHEEL CRANES

N6SERIES

ALWAYS SAVE THIS BOOK FOR FUTURE REFERENCE.

Thank you for purchasing the Kito N6 series Urethane wheel type Crane.

This crane has urethane coated steel track wheels. Light weight, quiet and stable,

the crane is designed to improve work efficiency.

Owing to thorough quality controls, this crane has been manufactured to satisfy

requirements for durability.

However, improper handling, usage or maintenance may result in unforeseen

accident or injury. Therefore, read thoroughly this manual before using the

equipment.

Application notes;

This manual is exclusively applied to N6C model cranes.Almost all parts of N6C model

cranes have no interchangeability with N6 model cranes.

All of N6C type end carriages can not be assembled with G1 type geared motor but with

G1B type geared motor only.

<CONTENS>

1. Definitions...............................................................................................................1

2. Intended purpose.....................................................................................................1

3. Before use ...............................................................................................................1

4. Cranes .....................................................................................................................3

5. Assembly, wiring and test run.................................................................................9

6. For better usage.....................................................................................................21

7. Maintenance and inspections ................................................................................21

8. track wheel disassembly and assembly.................................................................25

9. Power supply.........................................................................................................27

10. Troubleshooting ....................................................................................................28

11. Warranty................................................................................................................29

12. Parts list.................................................................................................................30

- 1 -

1. DEFINITIONS

DANGER : indicates an imminently hazardous situation which, if not avoided, will result

in death or serious injury.

WARNING : indicates a potentially hazardous situation which, if not avoided, could result

in death or serious injury.

CAUION : indicates a potentially hazardous situation which, if not avoided, may result

in minor or moderate injury. It may also be used to alert against unsafe

practices.

WLL: indicates maximum mass (working load limit) which a crane is designed to support in general service.

Under WLL, all values are indicated in t (ton).

2. INTENDED PURPOSE

This crane has been designed for vertically lifting, lowering and horizontally carrying loads by means of the

pendant push button switches, under normal atmospheric conditions of the work place.

3. BEFORE USE

3.1 Safety summary

Danger exists when heavy loads are transported, particularly when the equipment is not being used

properly or is poorly maintained. Because accidents and serious injury could result, special safety

precautions apply to the operation, maintenance and inspection of the KITO crane.

WARNING : ALWAYS operate, inspect and maintain this Crane in accordance with

applicable safety codes and regulations.

Following these simple rules can help to avoid hoisting accidents;

WARNING : IMPROPER crane use could result in death or serious injury. To avoid these

hazards.

3.1.1 Before and during operation

NEVER lift or transport loads over or near people.

NEVER use a crane for lifting, supporting or transporting people.

NEVER leave a suspended load unattended.

NEVER lift more than the rated capacity.

NEVER reverse crane operation abruptly or inch the crane excessively in travel.

- 2 -

NEVER pull a load from an extreme angle.

NEVER allow the crane to impact the stopper or other crane.

ALWAYS inspect the crane before use and at periodic intervals.

ALWAYS pay attention to load swing while operating the crane.

ALWAYS be aware of what is going on in the vicinity of the crane during use.

ALWAYS keep travel and traverse paths, and shelters, unobstructed.

ALWAYS operate the push buttons from a location from where both the hook and load can be seen.

ALWAYS check slings and loads are properly installed before use.

ALWAYS walk behind or alongside a suspended load, and keep eyes looking forward, while operating the crane.

ALWAYS read the “Safety Instructions” for your hoist and trolley respectively

provided.----------------------------------------------------------------------------------

3.1.2 Maintenance and checks

ALWAYS have maintenance, check and repairs performed by a qualified person.

ALWAYS place an “OUT OF SERVICE” sign on the crane when performing maintenance, checks or repairs.

ALWAYS turn OFF power to the hoist, trolley and crane before performing maintenance, checks

or repairs.

ALWAYS wear a helmet and safety belt when performing maintenance, checks or repairs.

- 3 -

4. Cranes

4.1 Features

[Geared motor]

(a) Employs an electromagnetic brake to mechanically adjust brake torque in stopping.

(b) Travel is kept quiet because of the helical gear used in the reduction gear.

(c) Comes in 3 models with different single speed specification (low, standard and high) and 1 model

with dual speed specification (Reduction ratio of 4:1).

[Low-head end carriage]

(a) Track wheels are easily taken off. This greatly shortens installation and maintenance work.

(b) High tension bolts (H.T.B) are used to couple the end carriage to the girder as standard for low-

head type.

(c) The center punch for girder installation holes is marked on the end carriage to make centering

easier.

(d) The end carriage is coated with a red primer when shipped from the factory.

(e) Travel is kept quiet with urethanecoated wheels. The wheels are cold and weather resistant, and

water resistant.

(f) Travel is kept quiet with a pinion L made from nylon. The pinion is weather and wear resistant.

(g) The end carriage uses press formed frames designed by Kito.

[Overhead end carriage]

(a) The end carriage has an open frame construction to facilitate track wheel maintenance.

(b) The end carriage is built with side rollers to keep travel smooth and stable.

(c) The centerpunchfor girder installation holes, girders andtravel rails are marked on theend carriage

to make centering easier.

(d) Span is easily adjusted on-site because the end carriage is coupled to the frame by bolts.

(e) The end carriage is coated with a red primer when shipped from the factory.

(f) Travel is kept quiet with urethanecoated wheels. The wheels are cold and weather resistant, and

water resistant.

(g) The end carriage uses press formed frames designed by Kito.

[Double girder end carriage]

(a) The end carriage has an open frame construction to facilitate track wheel maintenance.

(b) The end carriage is built with side rollers to keep travel smooth and stable.

(c) The center punch for girders and travel rails are marked on the end carriage to make centering

easier.

(d) The end carriage uses press formed frames (channel type) designed by Kito.

(e) The end carriage is coated with a red primer when shipped from the factory.

(f) Travel is kept quiet with urethanecoated wheels. The wheels are cold and weather resistant, and

water resistant.

- 4 -

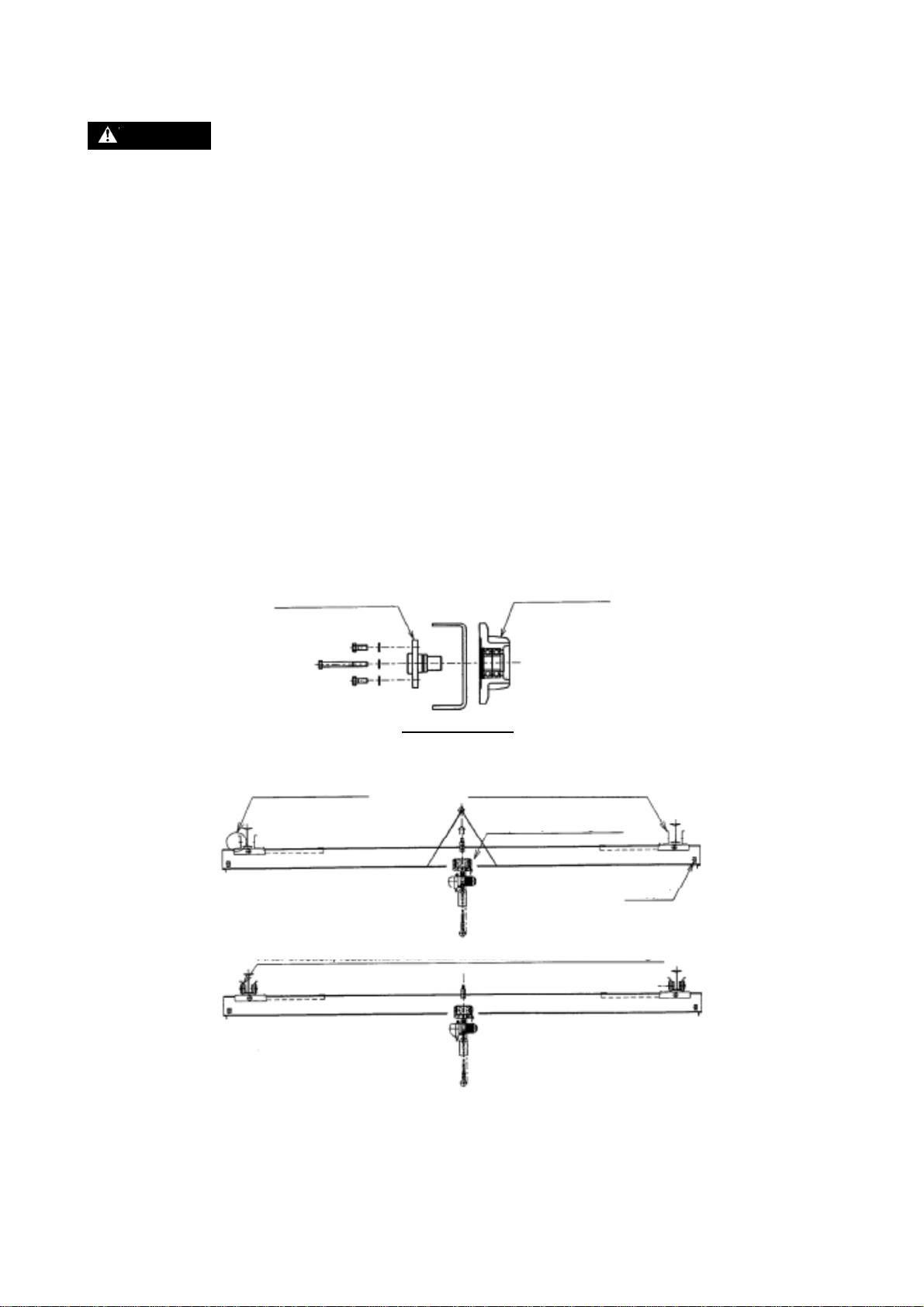

General view (For your reference)

[Low-head crane]

[Overhead crane]

[Double girder crane]

- 5 -

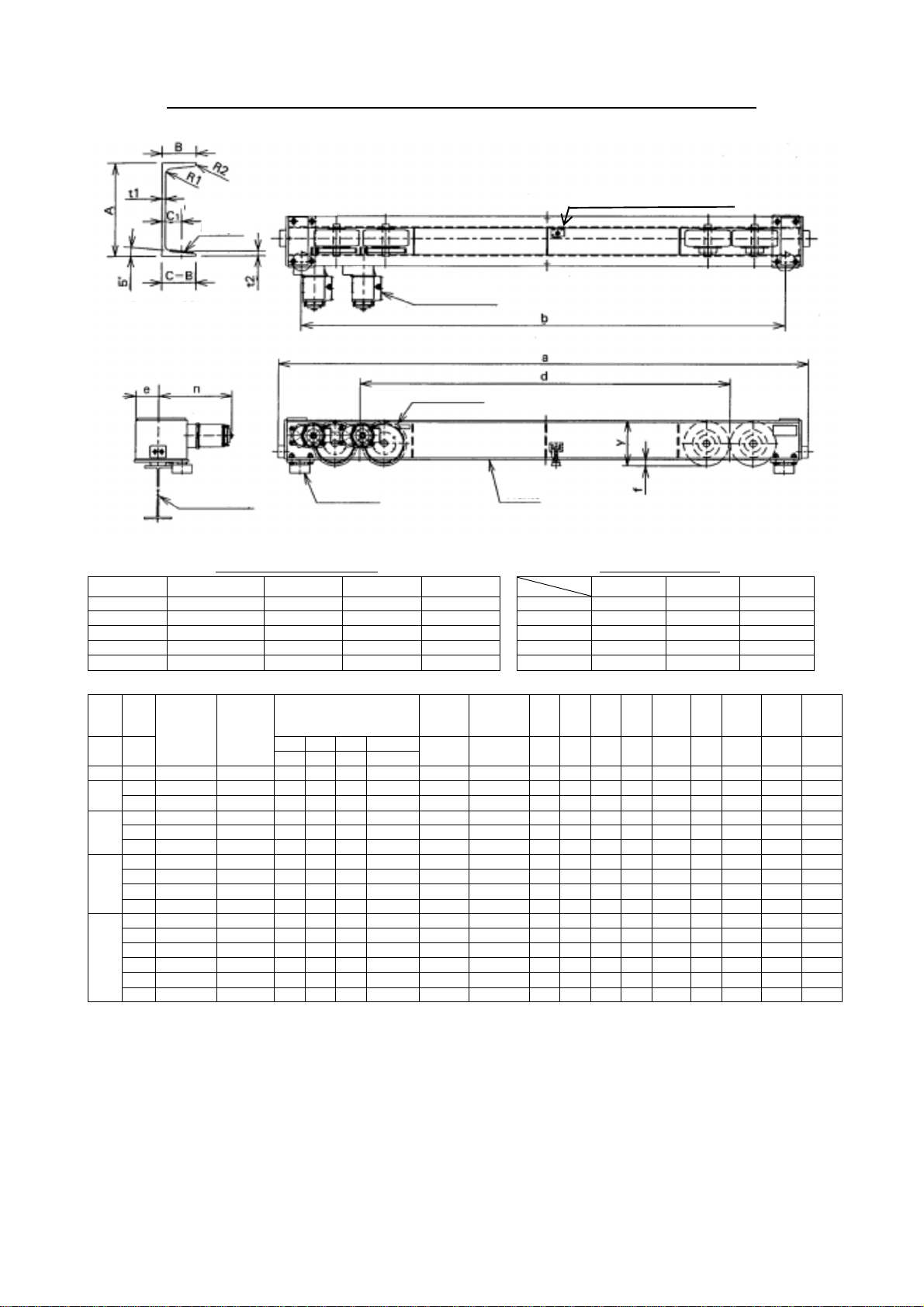

4.2 Specifications and outer appearance

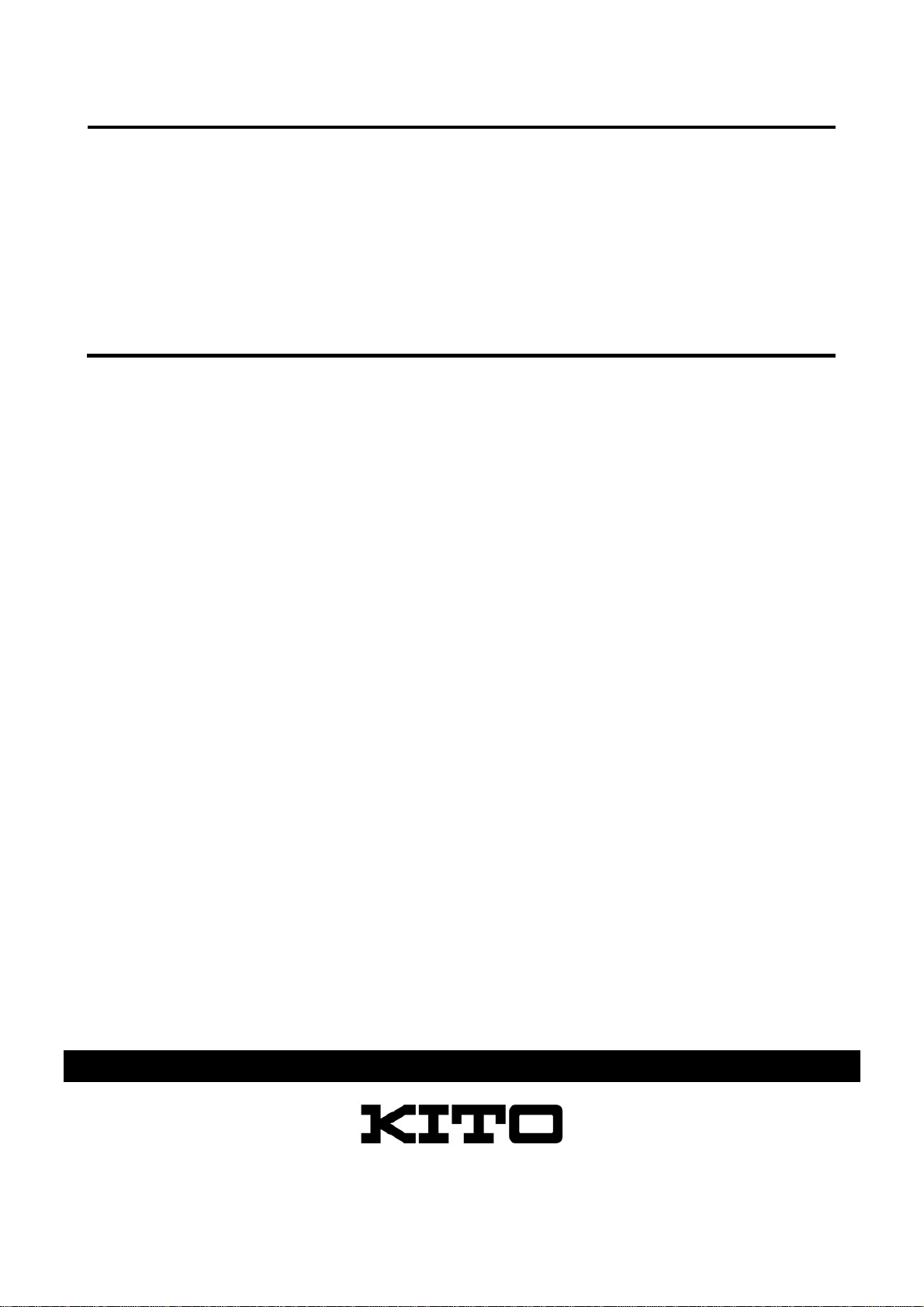

Urethane wheel low-head type motorized end carriage

Frame size ABCD (mm)

Span (m)

WLL (t) 6 9

1 15560606

2 20080809

WLL M

ax.

span Type Code Traveling motor output [kW2]

50/60Hz [m/min] Wheel

diameter

Applicable

traveling rail

width a d m u x *2y*1n

Max.

wheel

pressure

Net

weight

[t] [m] L S H SD [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [kg] [kg]

10/12 20/24 30/36 20:5/24:6

1 9 CEL010-9 N6CL310V 0.25 0.20 0.25 0.25/0.063 95 125 to 150 1500 1060 t+171 34 241-t/2 121 t/2+288 390 143

2 9 CEL020-9 N6CL320V 0.4 0.4 0.75 0.4/0.1 125 125 to 150 1500 1060 t+211 35 281-t/2 165 t/2+336 710 231

*1: Dimensions for standard speed geared motor

*2: Height from the traveling surface of the rail to the top point of the end carriage.

WLL: Working load limit

Travelling rail

Track wheel

Stay holder

Geared motor

Frame

Section of frame

Earth Device

(

Optio

nal ite

m

)

- 6 -

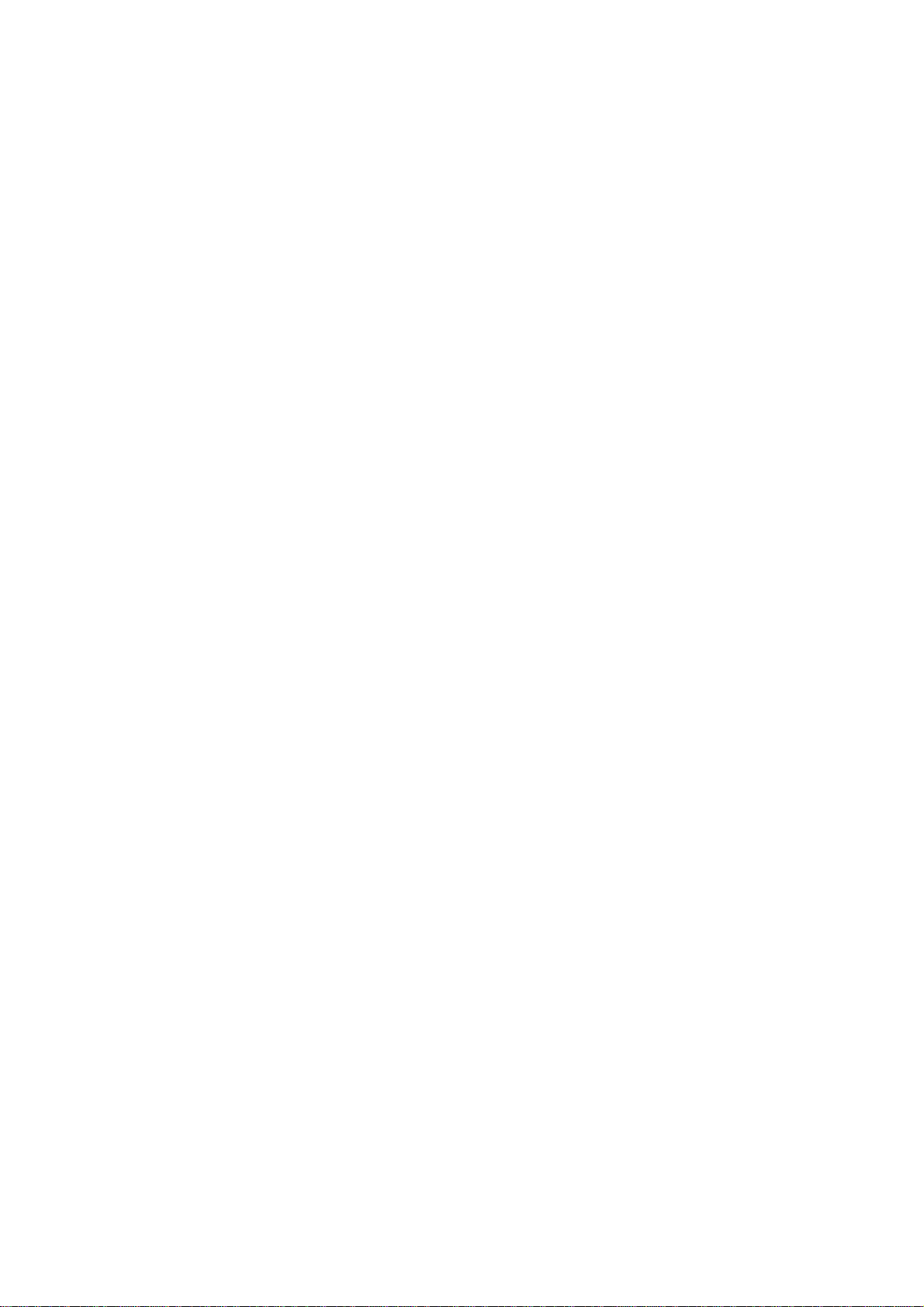

Urethane wheel overhead type motorized end carriage

Frame size ABCD (mm)

S

pan (m)

WLL (t)

9 12 15 18 21

1 15560606 20070706

2 1556060620095956 20090909

3 20095956

5 20095956 200808092401051059

7.5 200808092401051059

10 3001251259

WLL M

ax.

span Type Code Traveling motor output [kW2]

50/60Hz [m/min] Wheel

diameter

Applicable

traveling rail

width a d m u x *2y*1n

Max.

wheel

pressure Net weight

[t] [m] L S H SD [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [kg] [kg]

10/12 20/24 30/36 20:5/24:6

1

9 CEO010-9 N6CO310E 0.25 0.25 0.25 0.25/0.063 155 100 to 150 1586 1307 800 92 32 188 317 800 156

12 CEO020-12 N6CO420E 0.4 0.4 0.4 0.4/0.1 175 150 to 200 1696 1445 900 112 32 188 383 1500 202

18 CEO010-18 N6CO610E 0.4 0.4 0.4 0.4/0.1 175 150 to 200 2356 2105 1200 122 32 233 383 1500 265

21 CEO030-21 N6CO730E 0.75 0.75 0.75 0.75/0.19 220 150 to 200 2792 2499 1400 147 39 239 454 3400 502

2

12 CEO020-12 N6CO420E 0.4 0.4 0.4 0.4/0.1 175 150 to 200 1696 1445 900 112 32 188 383 1500 202

15 CEO030-15 N6CO530E 0.75 0.75 0.75 0.75/0.19 220 150 to 200 2082 1761 1000 152 39 239 451 3400 384

18 CEO030-18 N6CO630E 0.75 0.75 0.75 0.75/0.19 220 150 to 200 2422 2101 1200 152 39 239 451 3400 398

21 CEO030-21 N6CO730E 0.75 0.75 0.75 0.75/0.19 220 150 to 200 2792 2499 1400 147 39 239 454 3400 502

315 CEO030-15 N6CO530E 0.75 0.75 0.75 0.75/0.19 220 150 to 200 2082 1761 1000 152 39 239 451 3400 384

18 CEO030-18 N6CO630E 0.75 0.75 0.75 0.75/0.19 220 150 to 200 2422 2101 1200 152 39 239 451 3400 384

21 CEO030-21 N6CO730E 0.75 0.75 0.75 0.75/0.19 220 150 to 200 2792 2499 1400 147 39 239 454 3400 502

512 CEO050-12 N6CO450E 0.75 0.75 1.5 0.75/0.19 220 150 to 200 1852 1531 900 152 39 239 451 3400 355

18 CEO050-18 N6CO650E 1.5 1.5 1.5 1.5/0.38 260 150 to 200 2402 2106 1200 139 39 239 540 4200 543

21 CEO075-21 N6CO775E 1.5 1.5 1.5 1.5/0.38 340 150 to 200 2821 2506 1400 184 39 279 553 6300 665

7.5 12 CEO100-12 N6CO411E 1.5 1.5 1.5 1.5/0.38 340 150 to 200 2081 1766 900 159 39 239 553 6300 525

18 CEO075-18 N6CO675E 1.5 1.5 1.5 1.5/0.38 340 150 to 200 2421 2106 1200 184 39 279 553 6300 627

21 CEO075-21 N6CO775E 1.5 1.5 1.5 1.5/0.38 340 150 to 200 2821 2506 1400 184 39 279 553 6300 665

10 12 CEO100-12 N6CO411E 1.5 1.5 1.5 1.5/0.38 340 150 to 200 2081 1766 900 159 39 239 553 6300 525

21 CEO100-21 N6CO711E 1.5 1.5 1.52 1.5/0.38 440 200 to 250 2849 2509 1400 234 46 346 592 8300 1027[1220]

*1: Dimensions for standard speed geared motor

*2: height from the traveling surface of the rail to the top point of the end carriage.

WLL: Working load limit

Section of frame

Travelling rail

Track wheel

Frame

Side roller

Geared motor

Earth Device

(

Optio

nal ite

m

)

- 7 -

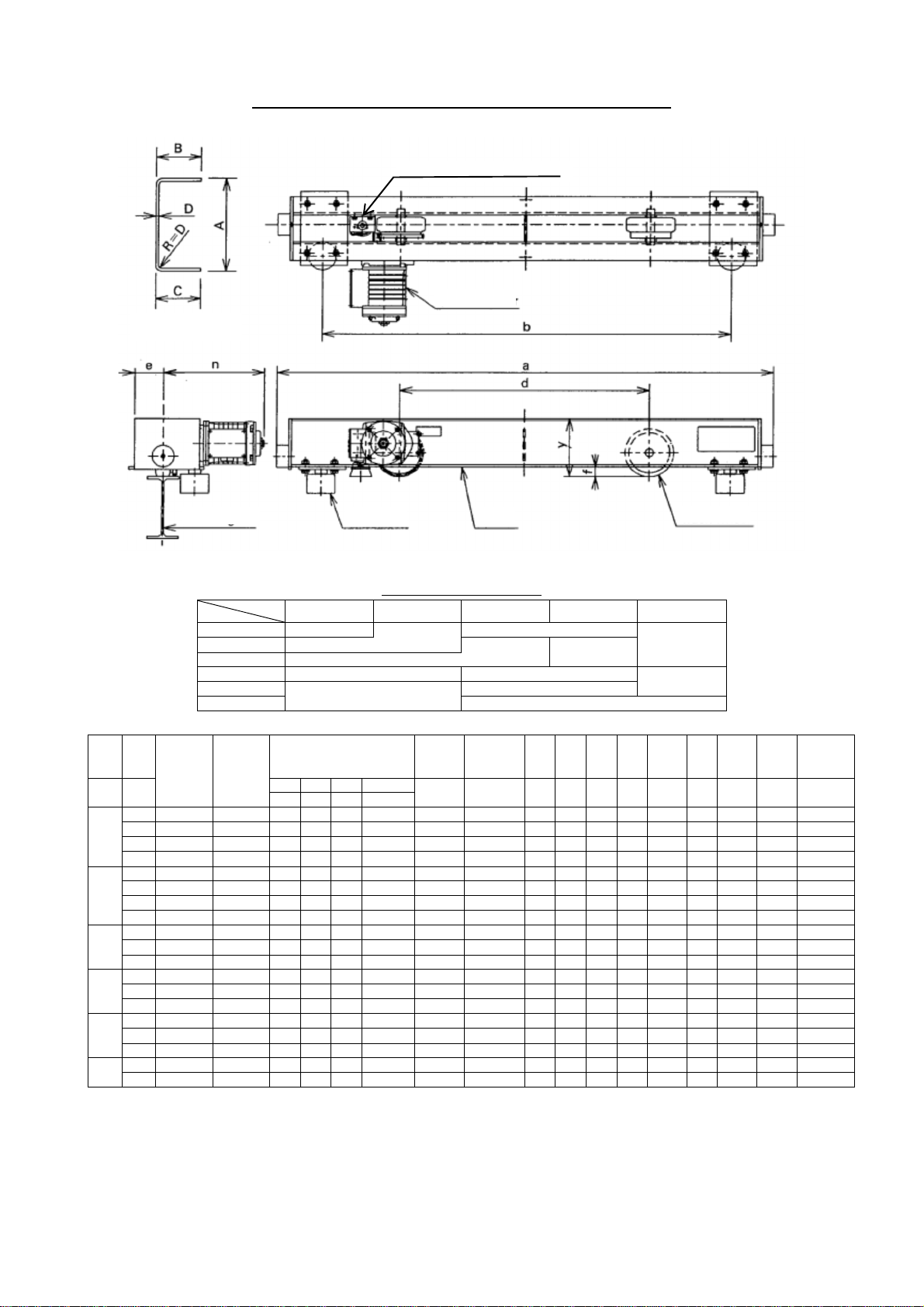

Urethane wheel overhead type double girder motorized end carriage (1)

Frame size ABt1t2 (mm) Symbol of frame size

Symbol Size R1 R2 C1

S

pan (m)

WLL (t)

15 21 27

FRM1 200807.511 12 6 47 3 FRM1 FRM1 FRM2

FRM2 25090913 14 7 53 5

7.5 FRM2

WLL M

ax.

span Type Code Traveling motor output [kW2]

50/60Hz [m/min] Wheel

diameter

Applicable

traveling rail

width a d m u x *2y*1n

Max.

wheel

pressure Net weight

[t] [m] L S H SD [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [kg] [kg]

10/12 20/24 30/36 20:5/24:6

315 WCO030-15 N6KO530E 0.75 0.75 1.5 0.75/0.19 220 150 to 200 2851 2539 2085 137 39 239 453 3400 524

21 WCO030-21 N6KO730E 1.5 1.5 1.5 1.5/0.38 260 150 to 200 3111 2796 2295 139 39 239 538 4200 653

27 WCO030-27 N6KO930E 1.5 1.5 1.5 1.5/0.38 300 150 to 200 3211 2896 2140 159 39 239 548 4400 881

515 WCO030-21 N6KO730E 1.5 1.5 1.5 1.5/0.38 260 150 to 200 3111 2796 2295 139 39 239 538 4200 653

21 WCO075-15 N6KO575E 1.5 1.5 1.5 1.5/0.38 340 150 to 200 3091 2776 2230 169 39 239 553 6300 930

7.5 15 WCO075-15 N6KO575E 1.5 1.5 1.5 1.5/0.38 340 150 to 200 3091 2776 2230 169 39 239 553 6300 930

*1: Dimensions for standard speed geared motor

*2: Height from the traveling surface of the rail to the top point of the end carriage.

WLL: Working load limit

Travelling rail

Track wheel

Frame

Side roller

Geared motor

C1: distance to middle of slope

5

slope

Section of frame

Earth Device

(

Optio

nal item

)

- 8 -

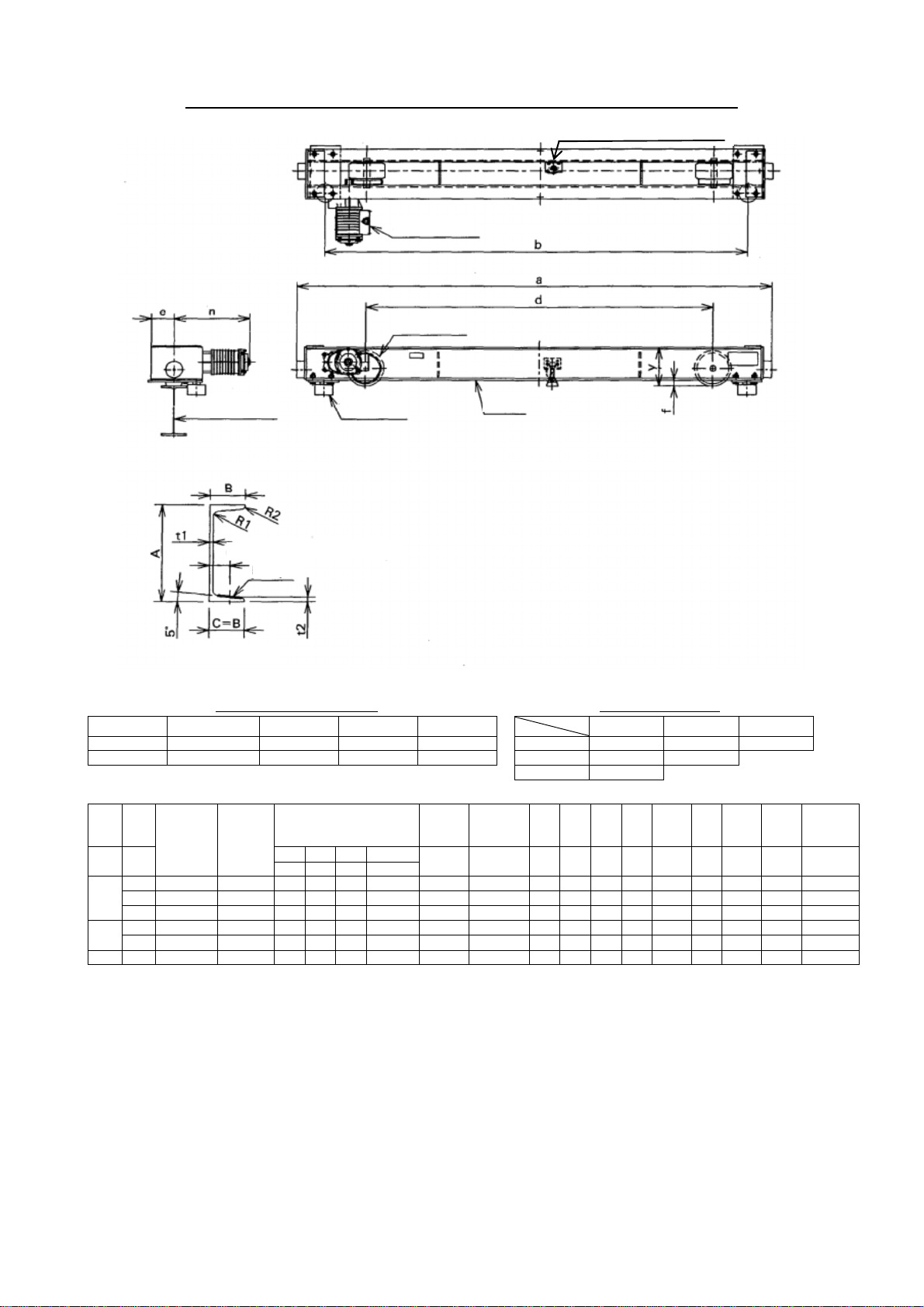

Urethane wheel overhead type with double girder motorized end carriage (2)

Frame size ABt1t2 (mm) Symbol of frame size

Symbol Size R1 R2 C1

S

pan (m)

WLL (t)

15 21 27

FRM1 25090913 14 7 53 5

FRM2 30090913 14 7 53 7.5 FRM1 FRM1 FRM2

FRM3 300901015.5 19 9.5 55 10

FRM4 38010010.516 18 9 60 15 FRM3 FRM4

FRM5 3801001320 24 12 62 20 FRM4 FRM5 FRM5

WLL M

ax.

span Type Code Traveling motor output [kW2]

50/60Hz [m/min] Wheel

diameter

Applicable

traveling rail

width a d m u x *2y *1n

Max.

wheel

pressure

Net

weight

[t] [m] L S H SD [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [kg] [kg]

10/12 20/24 30/36 20:5/24:6

5 27 WCO075-21 N6KO775E 1.52 1.52 1.52 1.5/0.382 2602 175 to 200 3771 3456 2700 149 39 289 540 4200 1150

7.5 21 WCO075-21 N6KO775E 1.52 1.52 1.52 1.5/0.382 2602 175 to 200 3771 3456 2700 149 39 289 540 4200 1160

27 WCO075-27 N6KO975E 1.52 1.52 1.52 1.5/0.382 3002 175 to 200 4059 3701 2900 159 46 346 548 4400 1438

10 15 WCO075-21 N6KO775E 1.52 1.52 1.52 1.5/0.382 2602 175 to 200 3771 3456 2700 149 39 289 540 4200 1160

21 WCO075-27 N6KO975E 1.52 1.52 1.52 1.5/0.382 3002 175 to 200 4059 3701 2900 159 46 346 548 4400 1438

27 WCO150-21 N6KO715E 1.52 1.52 1.52 1.5/0.382 3402 200 to 250 4412 4063 3220 179 46 426 554 6300 1672

15

15 WCO150-15 N6KO515E 1.52 1.52 1.52 1.5/0.382 3402 200 to 250 3992 3643 2790 169 46 346 554 6300 1378

21 WCO150-21 N6KO715E 1.52 1.52 1.52 1.5/0.382 3402 200 to 250 4412 4063 3220 179 46 426 554 6300 1672

27 WCO200-21 N6KO721E 1.52 1.52 - 1.5/0.382 3402 250 to 300 5172 4823 3800 209 46 426 593 8300 2575

27 WCO200-21 N6KO721E - - 2.22 - 4402 250 to 300 5292 4943 3840 209 46 426 709 8300 2700

20

15 WCO200-15 N6KO521E 1.52 1.52 - 1.5/0.382 4402 250 to 300 4742 4393 3380 209 46 426 593 8300 2214

15 WCO200-15 N6KO521E - - 2.22 - 4402 250 to 300 4872 4523 3420 209 46 426 709 8300 2336

21 WCO200-21 N6KO721E 1.52 1.52 - 1.5/0.382 4402 250 to 300 5172 4823 3800 209 46 426 593 8300 2575

21 WCO200-21 N6KO721E - - 2.22 - 4402 250 to 300 5292 4943 3840 209 46 426 709 8300 2700

27 WCO200-27 N6KO921E 1.52 1.52 - 1.5/0.382 4402 250 to 300 5422 5073 4070 209 46 426 593 8300 2944

27 WCO200-27 N6KO921E - - 2.22 - 4402 250 to 300 5552 5203 4110 209 46 426 709 8300 3071

*1: Dimensions for standard speed geared motor

*2: Height from the traveling surface of the rail to the top point of the end carriage.

WLL: Working load limit

distance to middle of slope

5

slope

Section of frame

Geared motor

Travelling rail

Side roller

Frame

Track wheel

Earth Device

(

Optio

nal ite

m

)

- 9 -

5. Assembly, wiring and test run

WARNING : ALWAYS make sure that the load supporting structures and load attaching

device are strong enough to hold the weight of load and hoist.

Have all assembly works by the authorized people. Off-limits to unauthorized

people in assembly works area.

5.1 Assembly

For detailed assembly instructions, refer to the urethane wheel crane’s assembly manual. The end

carriage can be easily set on the travel rails with the following procedure.

<Low-head type carriage>

(a) Detach all track wheels and axles from the end carriage as shown in Fig. 1.

The end carriage frame can be erected without detaching it from the girder. Reassemble the track

wheels and axles when the end carriage is in position.

There is always the risk of the hoist and trolley moving when installing, therefore it is easy to fix

them to the girder.Also, pay attention when assembling with the power supply cable, junction cable

and other accessories.

(b) Installing as shown in Fig. 1.

Fig. 1

Track wheel axle ass’y

Track wheel ass’y

Detail of track wheel

Track wheel position

Erect frame and girder together.

Fix the hoist and trolley to

the girder.

Stopper

After

erection, reassemble the track wheels and axles in the end carriage.

- 10 -

(c) Precautions in installation (Refer to Fig. 2)

Pay attention to the following points when coupling the end carriage to the girder on site.

Fig. 2

Keep the end carriage frames parallel (Aand B should be the same).

Minimize any discrepancy between the left and right end carriage frames position (D should be

minimized).

WARNING : If improperly assembled and installed, the crane will repeatedly strike the

stopper on the travel rail. This may cause bolts to loosen or other trouble.

Keep the end carriage at a right angle to the girder.

Minimize any discrepancy in angling between the left and right end carriage frames (X and Y

dimensions).

WARNING : When installing the hoist and trolley on the girder, refer to the “Safety

Instructions” for your hoist and trolley respectively provided.

<Overhead type crane>

(a) Generally, the simple way to erect the completed crane is shown in Fig. 3. Lift crane into position

of following figure, then turn the crane so as to fit on the travel rails.

Fig. 3

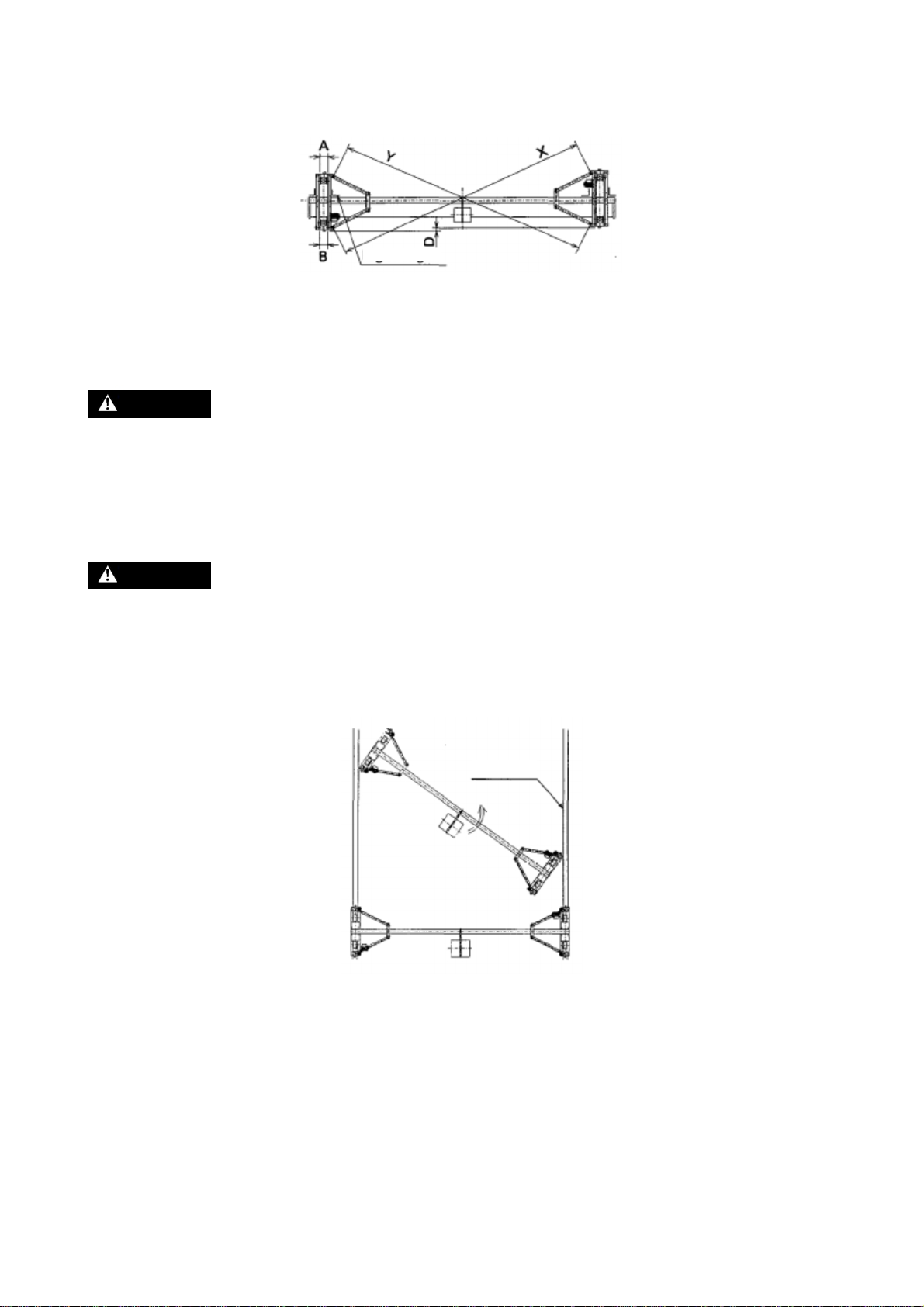

(b) Precautions in installation (Refer to Fig. 4).

The end carriage comes set at a right angle to the girder and squared to size when delivered,

nevertheless, pay attention to the following points when coupling the end carriage to the girder on-

site.

Right angle

Travel rail

- 11 -

Fig. 4

Minimize any discrepancy between the left and right end carriage frames position (D should be

minimized).

WARNING : If improperly assembled and installed, the crane will repeatedly strike the

stopper on the travel rail. This may cause bolts to loosen or other trouble.

Keep the end carriage at a right angle to the girder.

Minimize any discrepancy in angling between the left and right end carriage frames (X and Y

dimensions).

When using a urethane wheel crane, please lay a dedicated earth wire. When using an earth brush,

do not paint on the running surface of the track wheel. (Painting can also cause the track wheel to

slip)

WARNING : When installing the hoist and trolley on the girder, refer to the “Safety

Instructions” for your hoist and trolley respectively provided.

<Double girder crane>

Many double girder cranes come equipped with peripheral equipment and accessories, and there are

equally as many different ways to erect them.

(a) If the crane can be erected with the left and right end carriage frames attached to the girder, then

erect the crane according to the same procedure described for overhead cranes, check dimensions

after erecting the equipment, and adjust where necessary.

(b) If the crane cannot be erected with the left and right end carriage frames attached to the girder, then

first erect the end carriage frames on the travel rails as shown in Fig. 5. Next, turn the girders so as

to fit between the travel rails and lift into position, and attach the girders to the end carriage frames

on the travel rail.When assembling, set the end carriages to a right angle with the girder and square

with one another, and adjust span as necessary. (Refer to Fig.5)

Fig. 5

Right angle

- 12 -

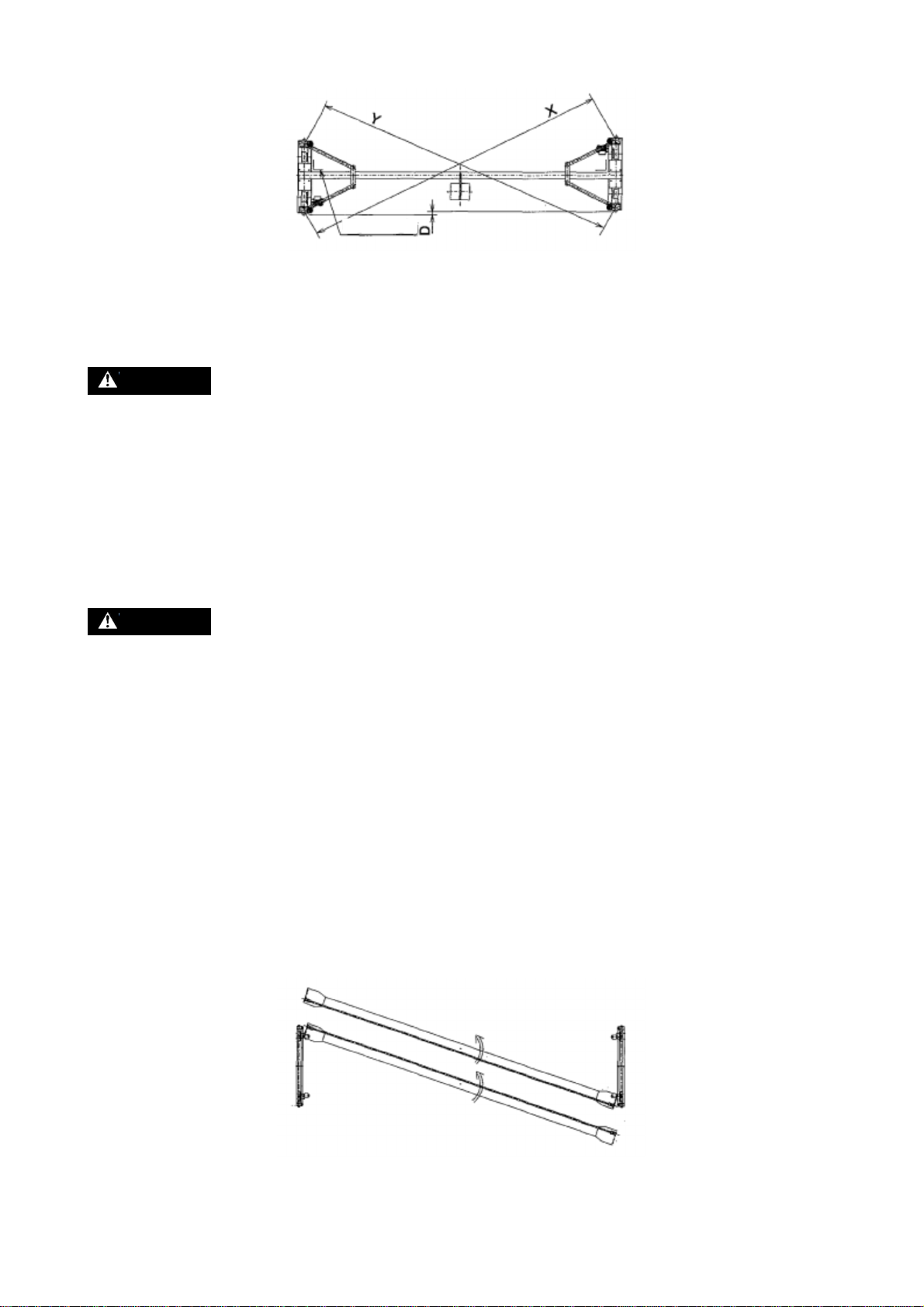

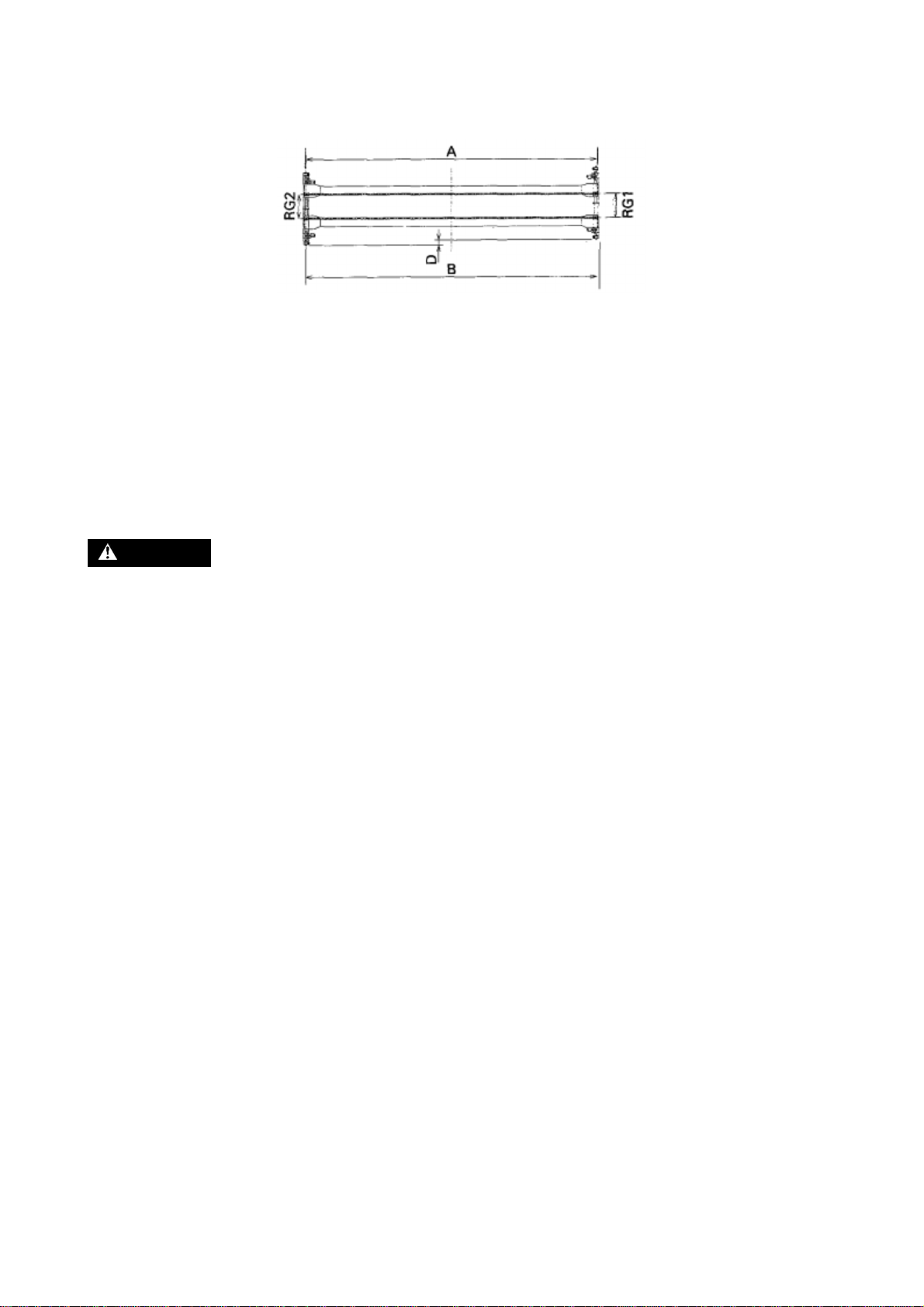

(c) Precautions in installation (Refer to Fig. 6).

Pay attention to the following points when coupling the end carriage to the girder on-site.

Fig. 6

Minimize any discrepancy between the left and right end carriage frames position (D should be

minimized). If improperly assembled and installed, the crane will repeatedly strike the stopper on

the travel rail. This may cause bolts to loosen or other trouble.

Minimize any discrepancy in rail gauge between the traverse rails (RG1 and RG2 dimensions9.

Keep the end carriage frames parallel (Aand B should be the same).

5.2 Wiring

DANGER : ALWAYS turn OFF power source or breaker switch to prevent electric shock

before beginning the wiring process.

HAVE all wiring performed by an authorized electrician.

Power can be supplied by the cable power supply, tro-reel, or trolley duct systems. For wiring from the

power source to the crane’s control box, refer to “9. Power supply” in this manual.

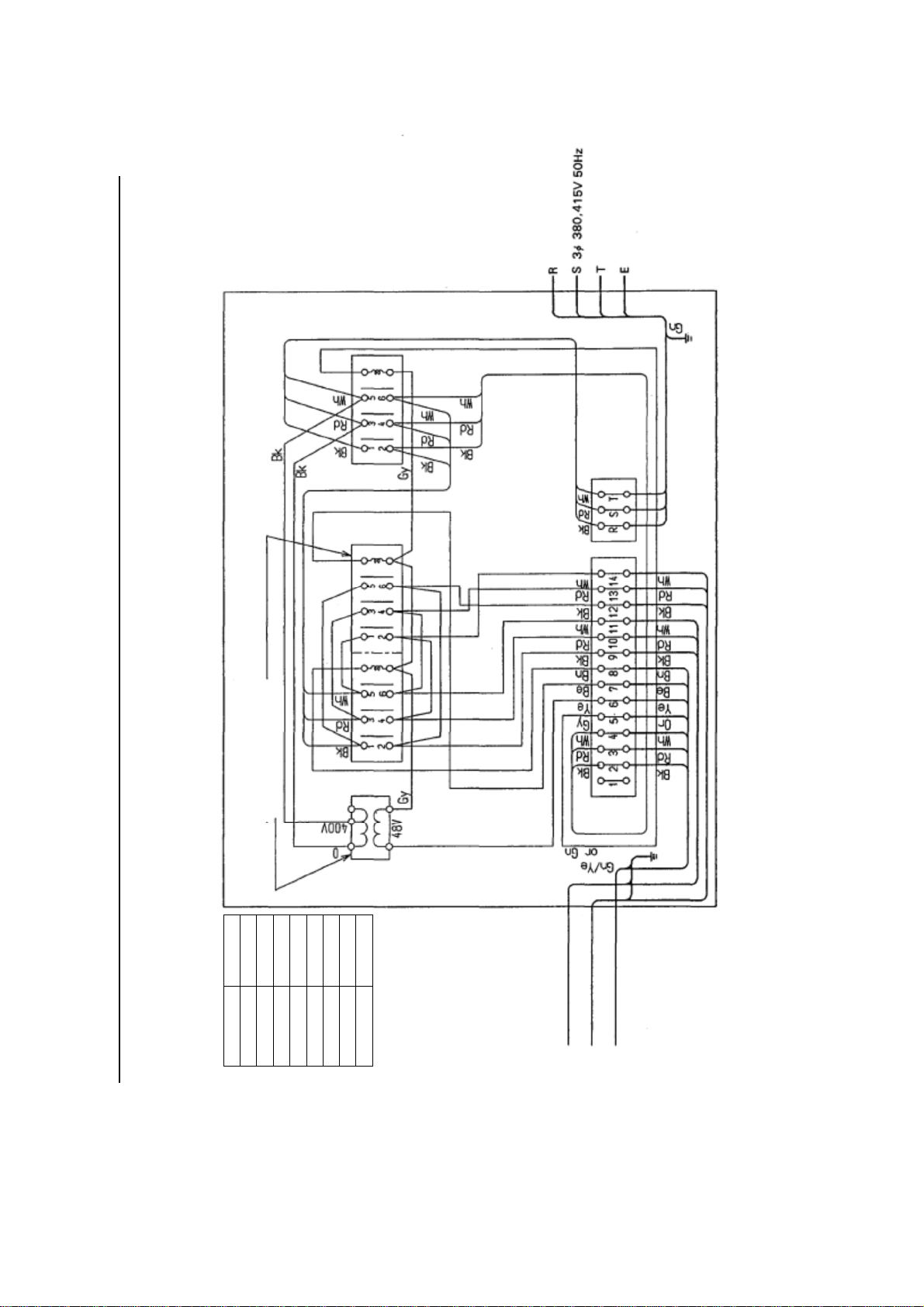

5.2.1 Control box internal wiring

Control box wiring differs depending on whether the emergency stop device (option) to the push

button switch is attached or not, and whether an electric chain hoist or rope hoist is used. Check

wiring diagrams before wiring.

For your reference, typical wiring schemes are shown in Figs. 7 through 12.

- 13 -

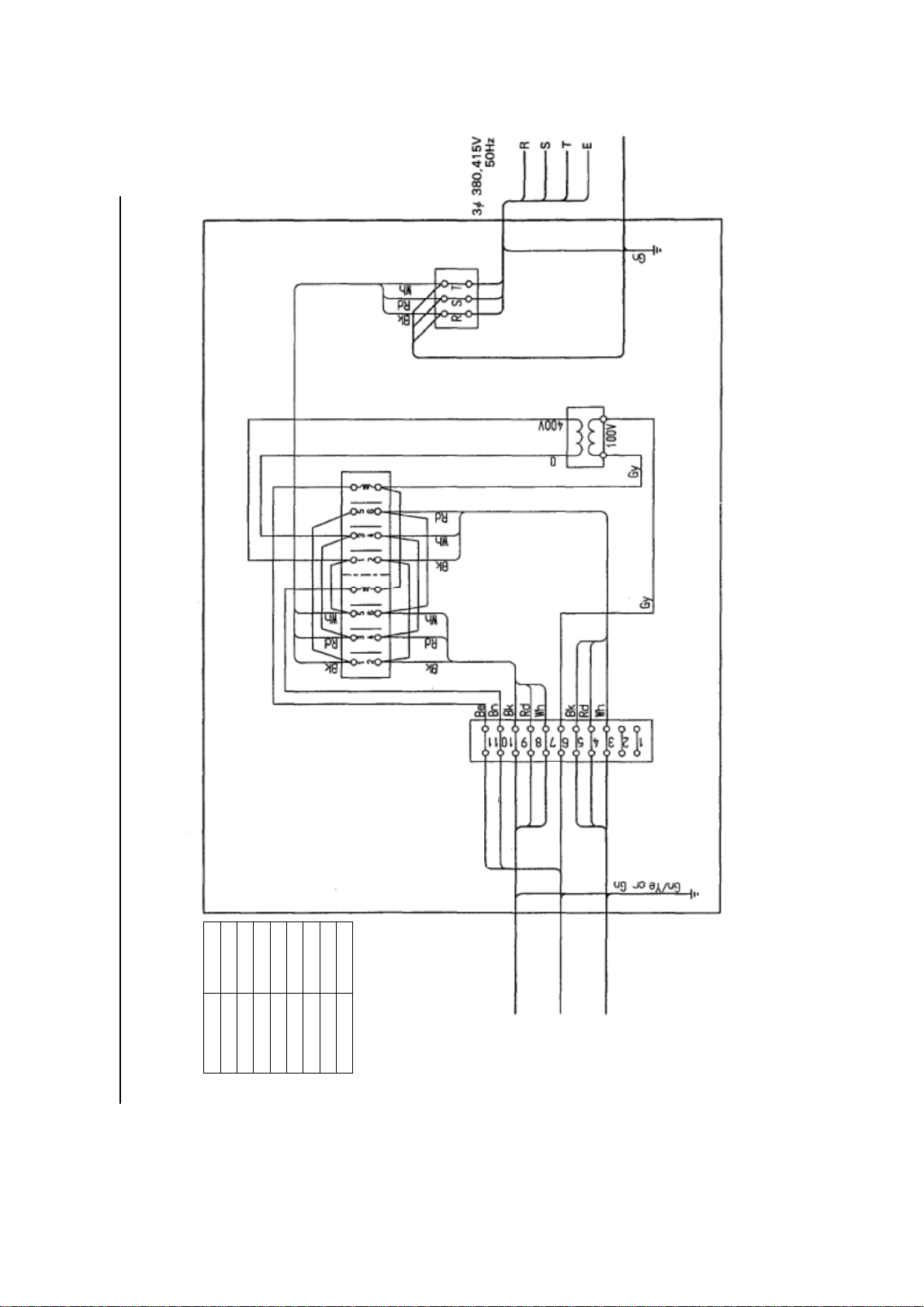

5.2.1

Electric traversing wire rope hoist with motorized trolley single speed (end carriage), without emergency stop device.

Hoist control

box

Fir travelling

Fir travelling

For control circuit

Geared motor

of crane

Hoist control box

Geared motor

of crane

Abbreviation

Bk

Rd

Wh

Gy

Bn

Be

Gn

Gn/Ye

Color

Black

Red

White

Gray

Brown

Blue

Green

Green & Yellow

Fig. 7

- 14 -

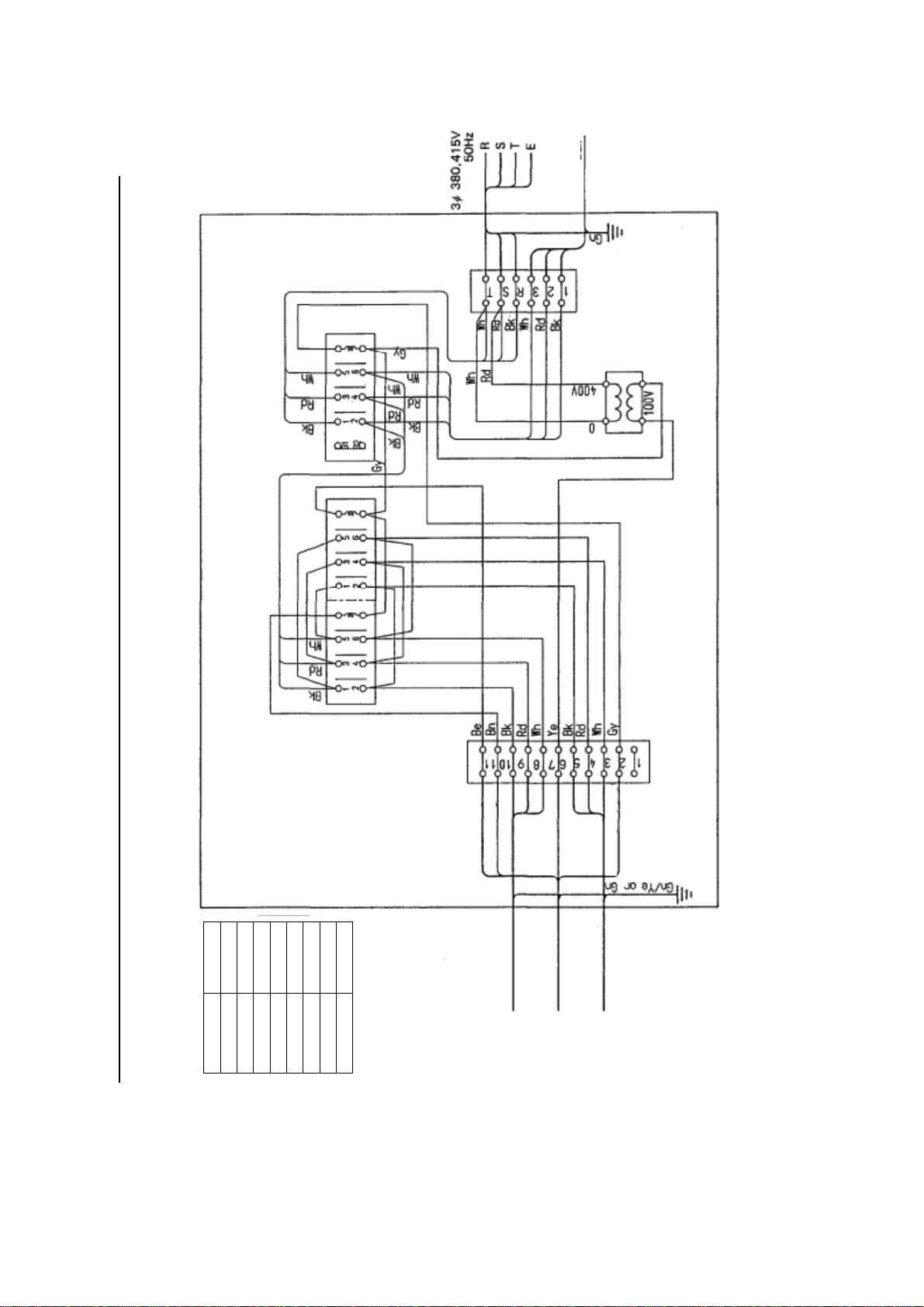

5.2.1

Electric traversing wire rope hoist with motorized trolley single speed (end carriage), without emergency stop device.

Fig. 8

Hoist control

box

Fir travelling

Fir travelling

Geared motor

of crane

Hoist control box

Geared motor

of crane

For

control circuit

For emergency stop

Abbreviation

Bk

Rd

Wh

Gy

Bn

Be

Gn

Gn/Ye

Color

Black

Red

White

Gray

Brown

Blue

Green

Green & Yellow

- 15 -

Abbreviation

Bk

Rd

Wh

Gy

Bn

Be

Gn

Gn/Ye

Color

Black

Red

White

Gray

Brown

Blue

Green

Green & Yellow

5.2.1

Electric traversing wire rope hoist with motorized trolley single speed (end carriage), without emergency stop device.

Fig. 9

Geared motor of crane

Electric Chain hoist

Geared motor of crane

Transformer

Electromagnetic contractor

* A disuse wire

among three wires of the primary side of the transformer shall be isolated and rolled to be fixed securely.

- 16 -

5.2.1

Electric traversing wire rope hoist with motorized trolley single speed (end carriage), without emergency stop device.

Fig. 10

Geared motor of crane

Electric Chain hoist

Geared motor of crane

Transformer

Electromagnetic contractor

Abbreviation

Bk

Rd

Wh

Gy

Bn

Be

Gn

Gn/Ye

Color

Black

Red

White

Gray

Brown

Blue

Green

Green & Yellow

- 17 -

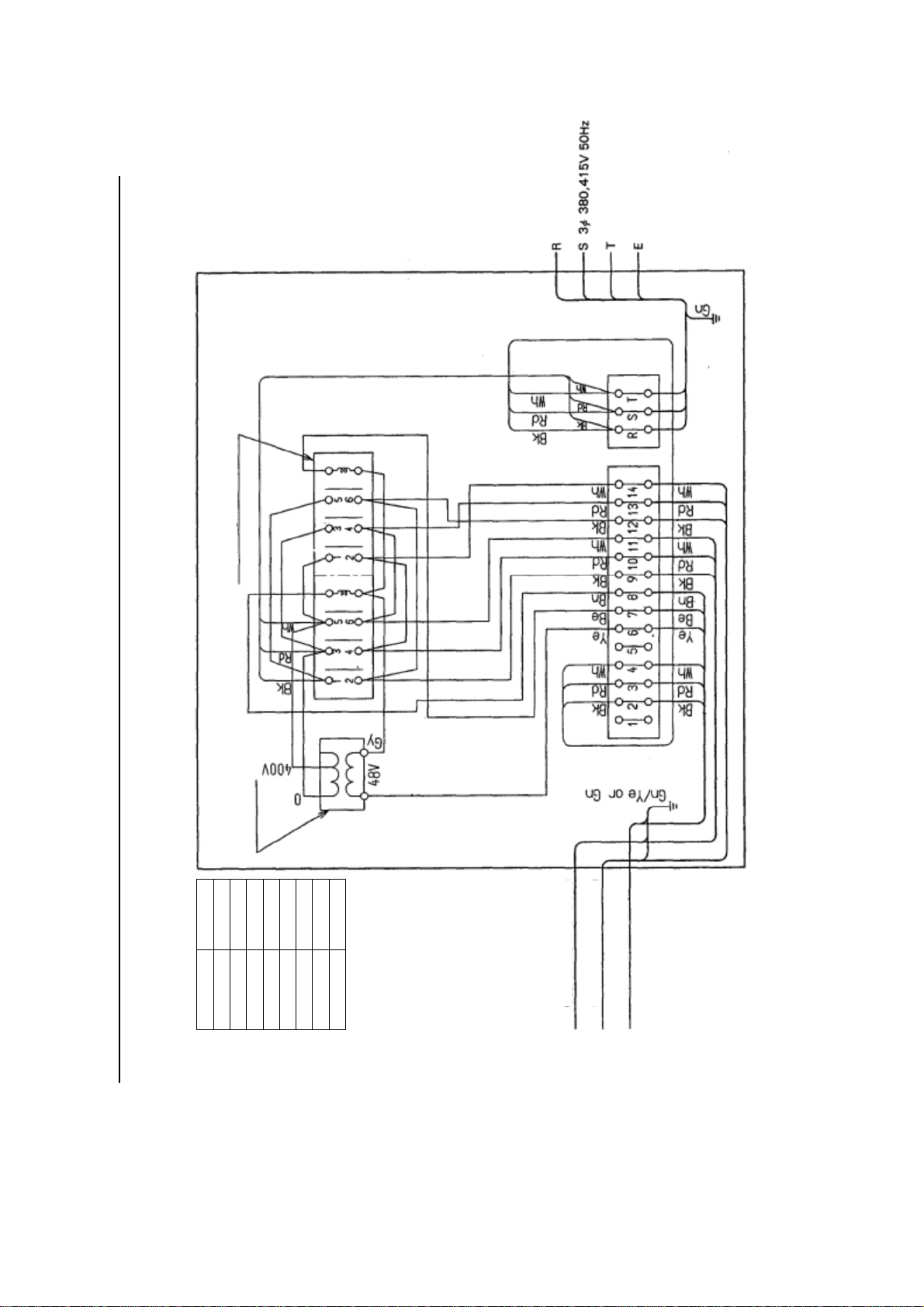

5.2.1

Electric traversing wire rope hoist with

motorized trolley single speed (end carriage), without emergency stop device.

Fig. 11

Geared motor

of crane

Electromagnetic

contractor

Abbreviation

Bk

Rd

Wh

Gy

Bn

Be

Gn

Gn/Ye

Color

Black

Red

White

Gray

Brown

Blue

Green

Green & Yellow

Transformer

Geared motor

of crane

Electric Chain

hoist

- 18 -

5.2.1

Electric

chain

hoist with motorized trolley

, dual

speed (end carriage), with emergency stop device.

Fig. 12

Geared motor

of crane

Electric Chain

hoist

Geared motor

of crane

Transformer

Electromagnetic

contractor

Timer

Abbreviation

Bk

Rd

Wh

Gy

Bn

Be

Gn

Gn/Ye

Color

Black

Red

White

Gray

Brown

Blue

Green

Green & Yellow

Table of contents

Other KITO Construction Equipment manuals

Popular Construction Equipment manuals by other brands

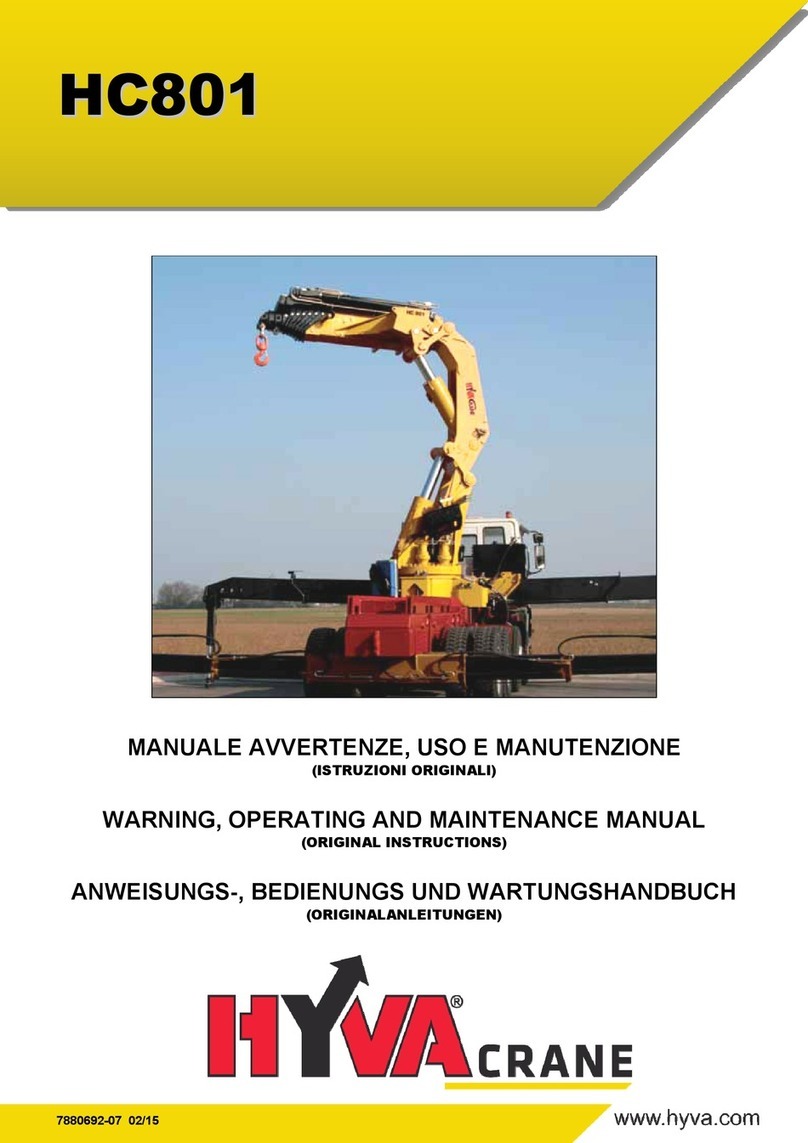

HYVA

HYVA HC801 WARNING, OPERATING AND MAINTENANCE MANUAL

Delta Kitchen

Delta Kitchen 16929 Series Installation instruction

IMER

IMER KOINE 4 OPERATION, MAINTENANCE AND SPARE PARTS MANUAL

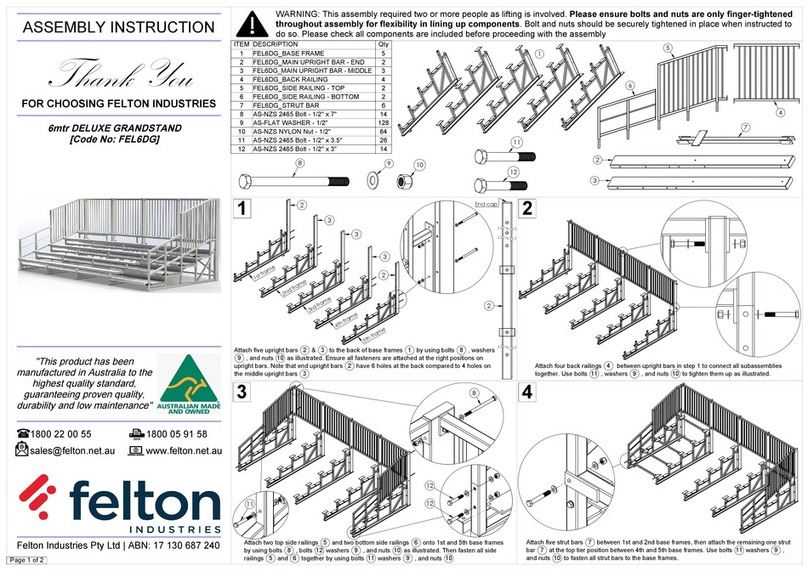

felton industries

felton industries DELUXE GRANDSTAND FEL6DG Assembly instruction

Titan

Titan SteamMaster operating manual

Kubota

Kubota KC120HC Operator's manual