3

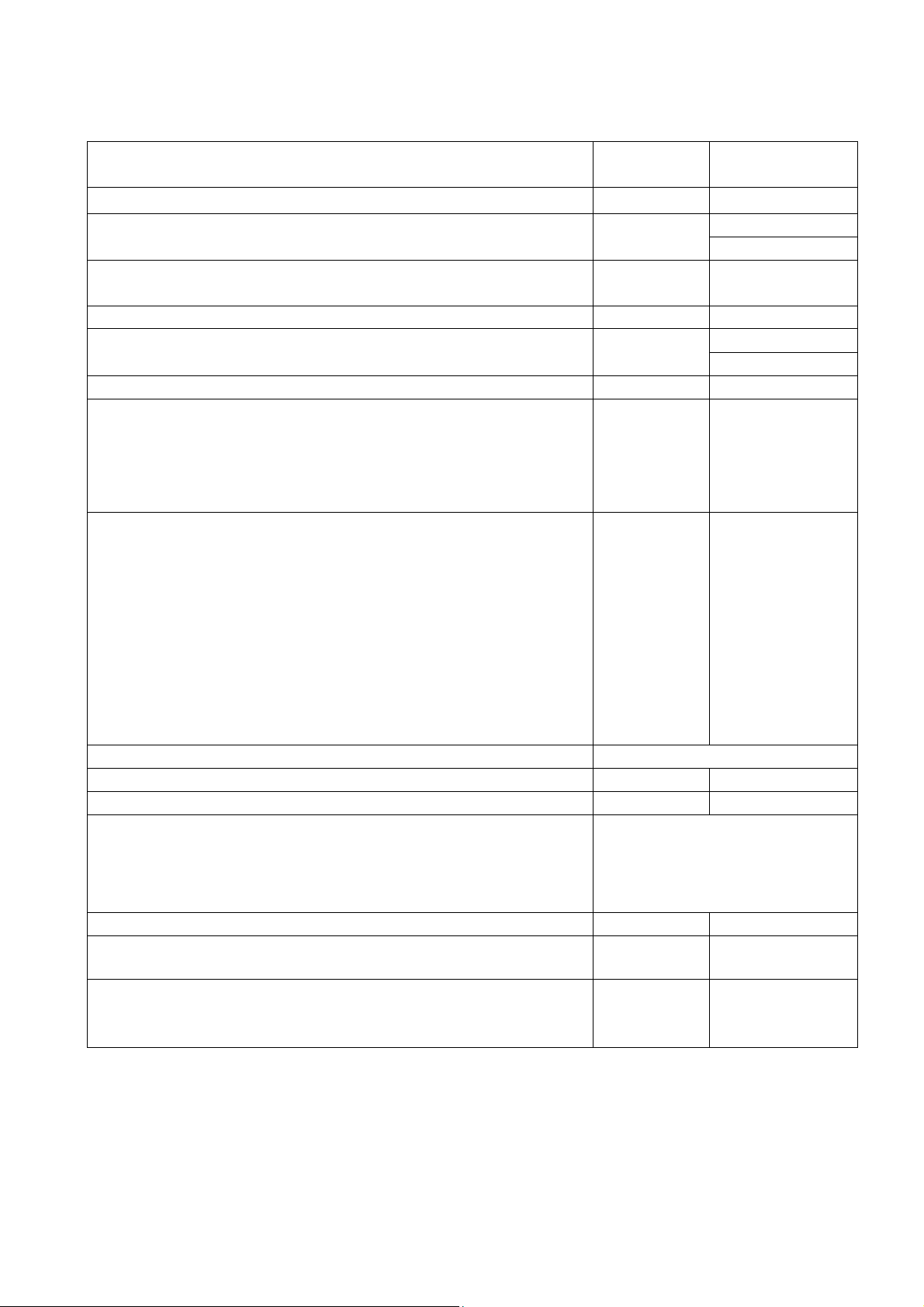

Content

Operation Manual .................................................................................................................................... 4

1

General .............................................................................................................................................. 5

2

Specifications ...................................................................................................................................... 7

3

Product design and operation ............................................................................................................... 8

3.1

Device components ............................................................................................................................. 8

3.2

Design and operation of the mower and its main parts .......................................................................... 8

3.2.1

Drive ......................................................................................................................................... 9

3.2.2

Traction fuse ............................................................................................................................ 10

3.2.3

Cutter bar ................................................................................................................................ 11

3.2.3.1 Replacement of rotor blades of the cut device ....................................................................... 12

3.2.4

Hydraulic circuit ........................................................................................................................ 14

3.2.5

Balancing mechanism ............................................................................................................... 14

4

Safety requirements .......................................................................................................................... 15

5

General requirements to prepare the mower for operation, during operation, maintenance, transportation .... 15

5.1

Fire fighting measures ....................................................................................................................... 16

5.2

Nameplates (applications) with signs and inscriptions .......................................................................... 16

5.3

Critical Failure List ............................................................................................................................. 21

5.4

Possible erroneous actions that may lead to an accident ...................................................................... 21

5.5

Staff action in the event of unforeseen circumstances .......................................................................... 22

5.5.1

Qualification of the operator and service personnel ..................................................................... 22

5.5.2

Unexpected circumstances ........................................................................................................ 22

5.5.3

Staff actions ............................................................................................................................. 23

6

Control mechanisms .......................................................................................................................... 24

7

Additional assembly, adjustment and trial run ..................................................................................... 25

7.1

Mounting and assembly of mowers ..................................................................................................... 25

7.2

Preparation of the tractor hitch system for working with mowers .......................................................... 25

7.3

Preparation of the tractor for mower hanging ...................................................................................... 25

7.4

Mounting of mower to tractor ............................................................................................................. 25

7.5

Mower trial run .................................................................................................................................. 26

8

Operation and adjustments ................................................................................................................ 28

9

Maintenance ..................................................................................................................................... 29

9.1

General ............................................................................................................................................. 29

9.2

Maintenance activities ........................................................................................................................ 29

9.2.1

List of works performed at SM ................................................................................................... 29

9.2.2

List of works performed in preparation for storage ..................................................................... 29

9.2.3

List of works performed during storage ...................................................................................... 29

9.2.4

List of works to be performed upon removal from storage .......................................................... 30

8.3 Mower lubrication .............................................................................................................................. 30

8.3.1 Lubrication of cut device .................................................................................................................. 31

Transportation ..................................................................................................................................... 33

10

Storage ........................................................................................................................................... 34

11

List of possible malfunctions and instructions for their elimination ..................................................... 35

12

Limit conditions for mowers ............................................................................................................. 36

13

Decommissioning and disposal ......................................................................................................... 37

Annex А (mandatory) Principal kinematic diagram of mower ZTT-3,2 ............................................................. 38

Catalog of parts an assembly units ..................................................................................................... 39

1

Illustrations and a list of assembly units and parts ............................................................................... 41

General .................................................................................................................................................. 42

Hitch ...................................................................................................................................................... 43

Fuse installation ...................................................................................................................................... 45

Hanging and lifting mechanism ................................................................................................................ 47

Spring Blocks ........................................................................................................................................... 49

Installation of a small beam ..................................................................................................................... 51

Installation of drive ................................................................................................................................. 53

Fencing and frame .................................................................................................................................. 55

Field division unit .................................................................................................................................... 56

Cut device with reducer ........................................................................................................................... 58

Cut unit with reducer ............................................................................................................................... 60

Hydraulic equipment ............................................................................................................................... 61

2

Numbered index ................................................................................................................................ 62