- 4 -

1400_GB-INHALT_2620

EN

TABLE OF CONTENTS

Observe Sa-

fety Hints in

the supple-

ment!

CE sign

The CE sign, which is affixed

by the manufacturer, indicates

outwardly that this machine

conforms to the engineering

guideline regulations and the

other relevant EU guidelines.

EU Declaration of Conformity

By signing the EU Declaration of Conformity, the

manufacturer declares that the machine being brought

into service complies with all relevant safety and health

requirements.

Meaning of warning signs

Never reach into the crushing danger area as long as

parts may move.

Do not enter rotor area while driving motor is running.

Table of contents

TABLE OF CONTENTS

CE sign ...................................................................... 4

Meaning of warning signs.......................................... 4

OVERVIEW

Overview.................................................................... 5

WARNING SIGNS

Meaning of warning signs.......................................... 6

Position of the warning signs ..................................... 7

ATTACHING

Attaching of machines with 3-point hitch .................. 8

Swing headstock locking during road drive and for

parking....................................................................... 8

Parking the implement ............................................... 9

TRANSPORT AND WORKING POSITION

Switching to transport position................................. 10

Transport runs.......................................................... 10

Driving on public roads .............................................11

Change to working position ......................................11

OPERATION

General guidelines on working with the machine .... 12

Working on slopes ................................................... 13

P.t.o. speed .............................................................. 13

Hydraulic lower link.................................................. 13

Setting the lifting support for the swath curtain.........14

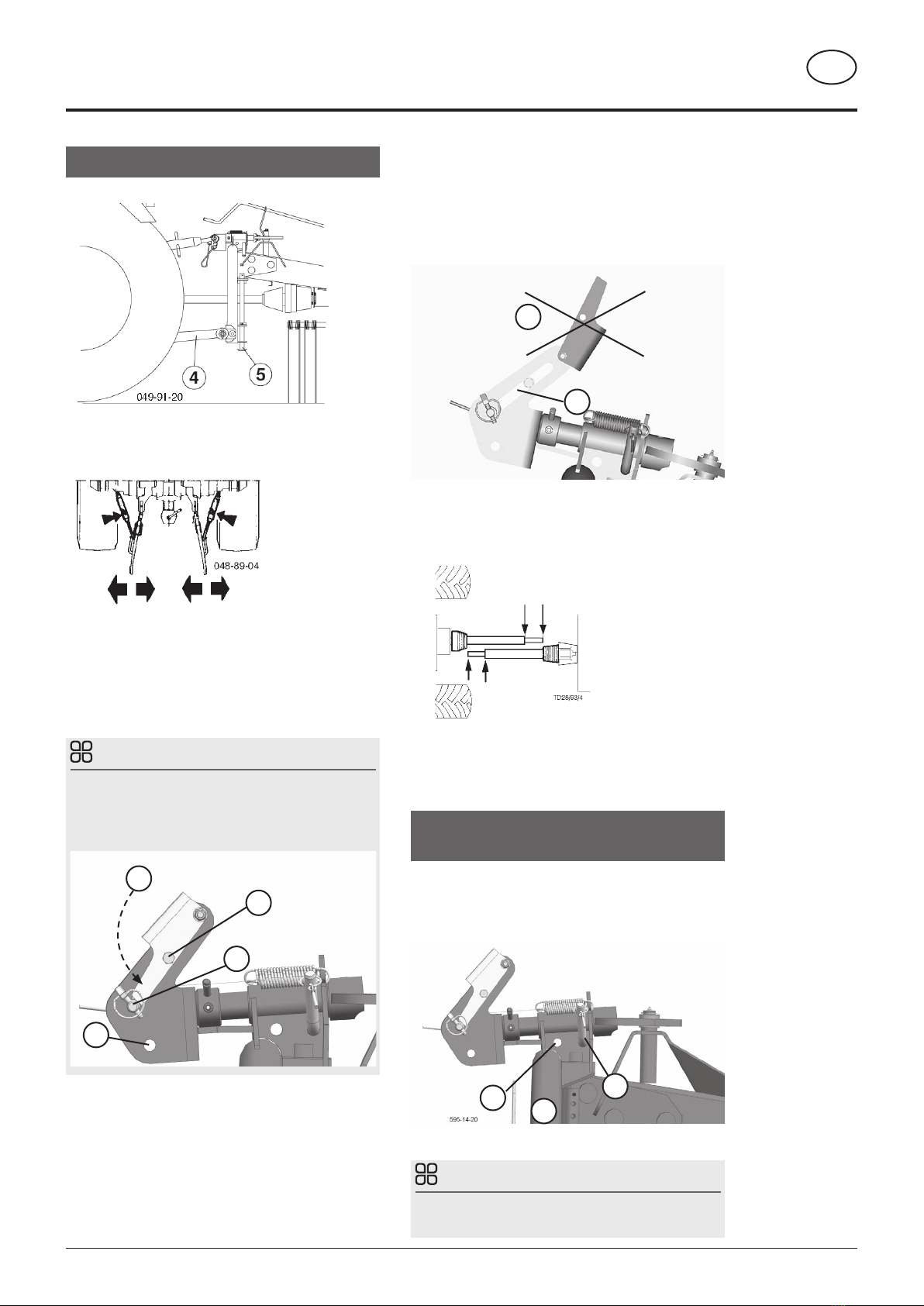

Jockey wheel (5).......................................................14

Setting gyroscope inclination (without jockey

wheel) .......................................................................14

Setting gyroscope height ..........................................14

Tandem axle (optional fitting)....................................14

Hydraulic folding of the swath guard (optional

fitting)....................................................................... 15

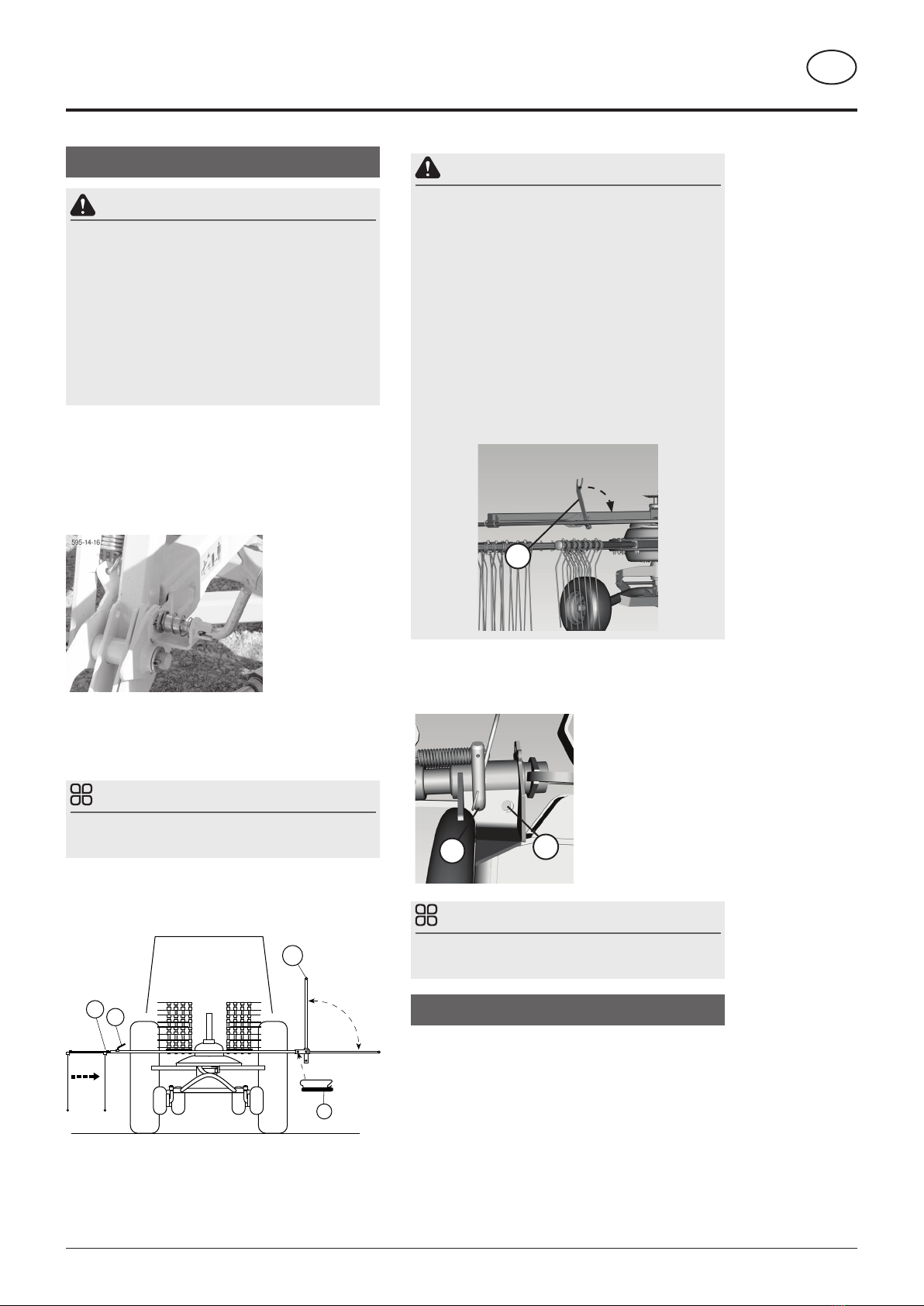

Mechanical folding of safety brackets...................... 15

Setting the cam track............................................... 15

MAINTENANCE

Safety advice ............................................................17

Maintenance and Repairs.........................................17

Cardans ....................................................................17

Cleaning of machine parts........................................17

Winter storage...........................................................17

Lubrication chart ...................................................... 18

Tine arms................................................................. 19

Rotor unit ................................................................. 20

Spring tines.............................................................. 21

Lubrication chart ...................................................... 22

TECHNICAL DATA

Technical data.......................................................... 23

Appropriate use ....................................................... 23

Position of type plate................................................ 23

Special equipment: .................................................. 23

SUPPLEMENT

SAFETY ADVICE

Lubricants ................................................................ 30

Combination of tractor and mounted implement...... 33