TABLE OF CONTENTS

1. INTRODUCTION......................................................................................................................... 4

2. CHECKLIST................................................................................................................................ 5

3. COMPONENTS ......................................................................................................................... .7

4. SPECIFICATIONS. ..................................................................................................................... 7

5. WARNINGS ................................................................................................................................ 8

6. RECOMMENDED MAXIMUM MOISTURE CONTENT FOR SAFE STORAGE (wet basis)...... 8

7. SMALL PARTS ........................................................................................................................... 9

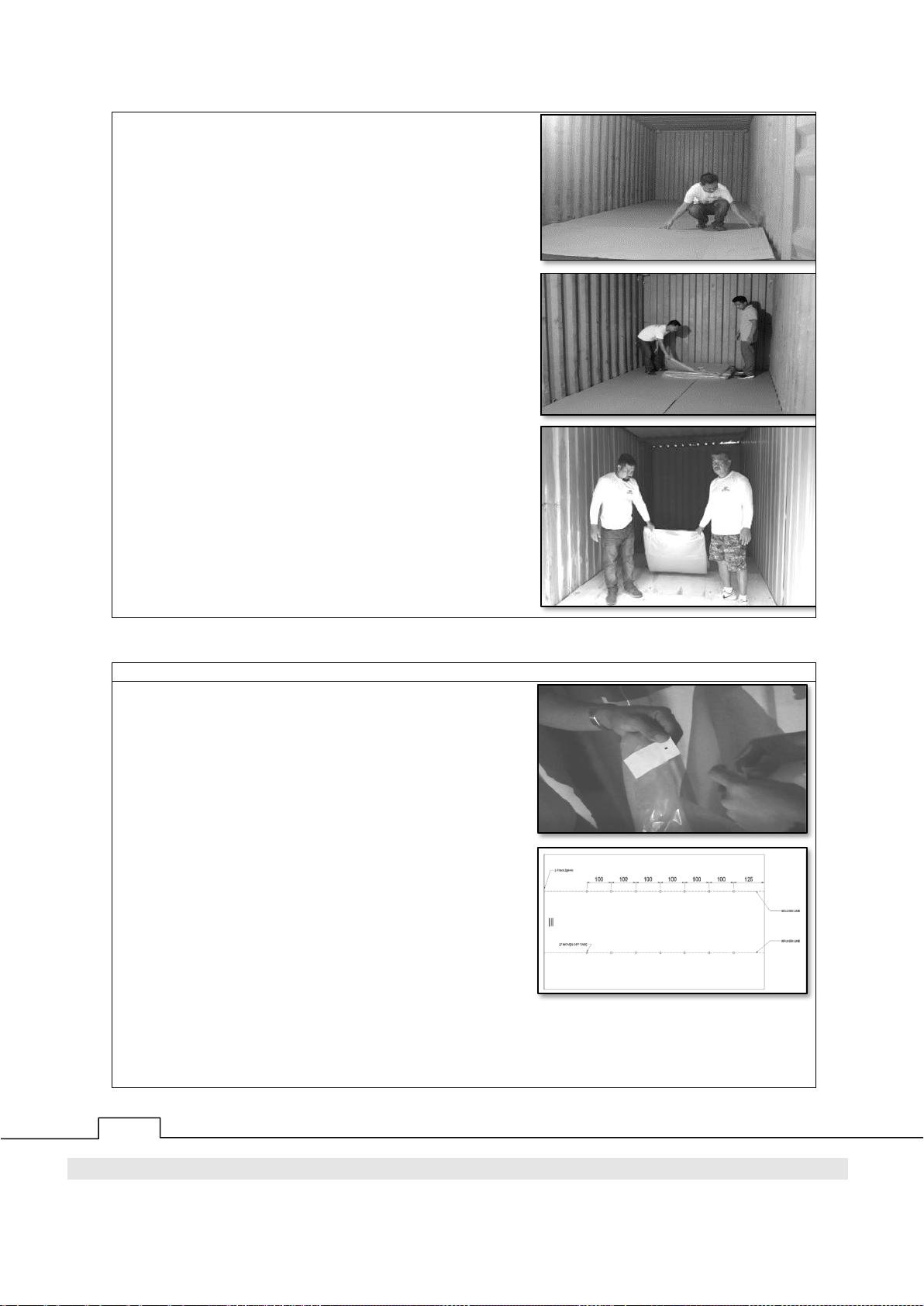

8. INSTALLATION........................................................................................................................... 9

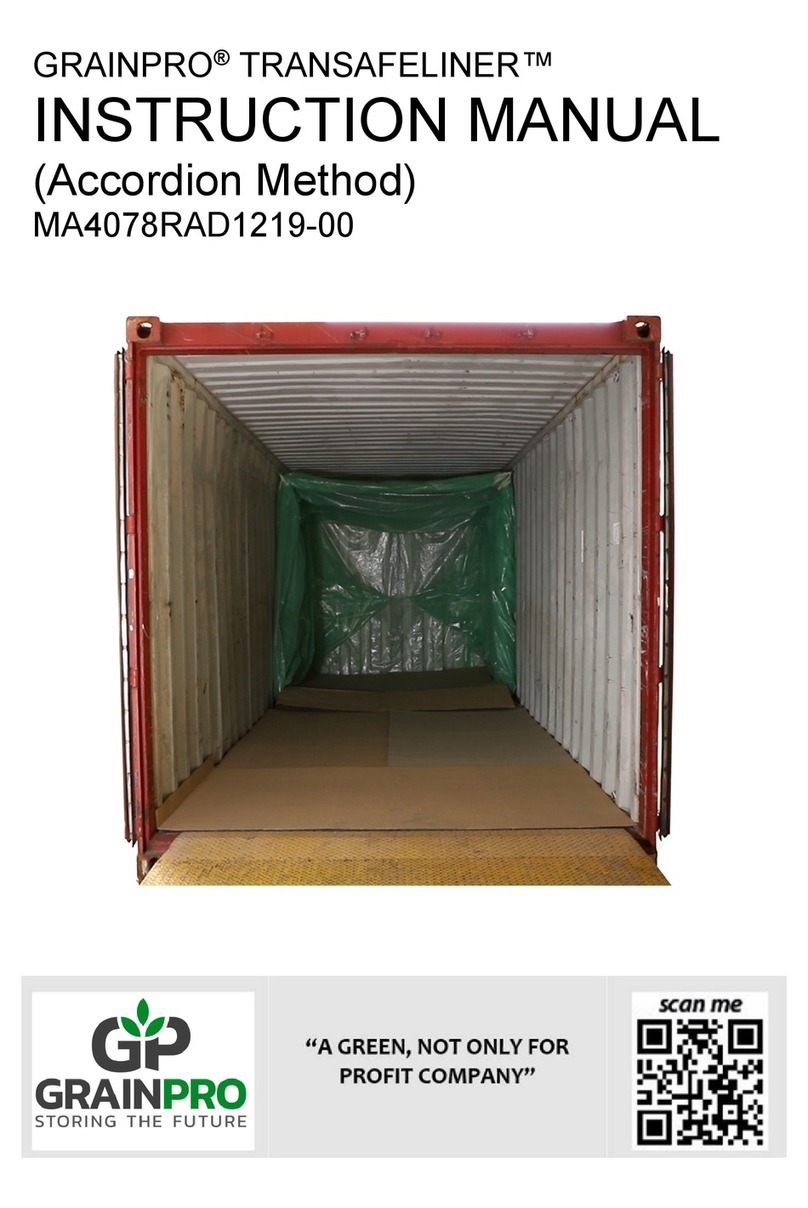

Preparation ........................................................................................................................... .9

Attachment of Rope Braces………………………………………………………………………10

Bulkhead Installation............................................................................................................11

TSL Blower Installation........................................................................................................ 12

TSL Blower (Not Included) Components and Specifications………...……………….………….....…12

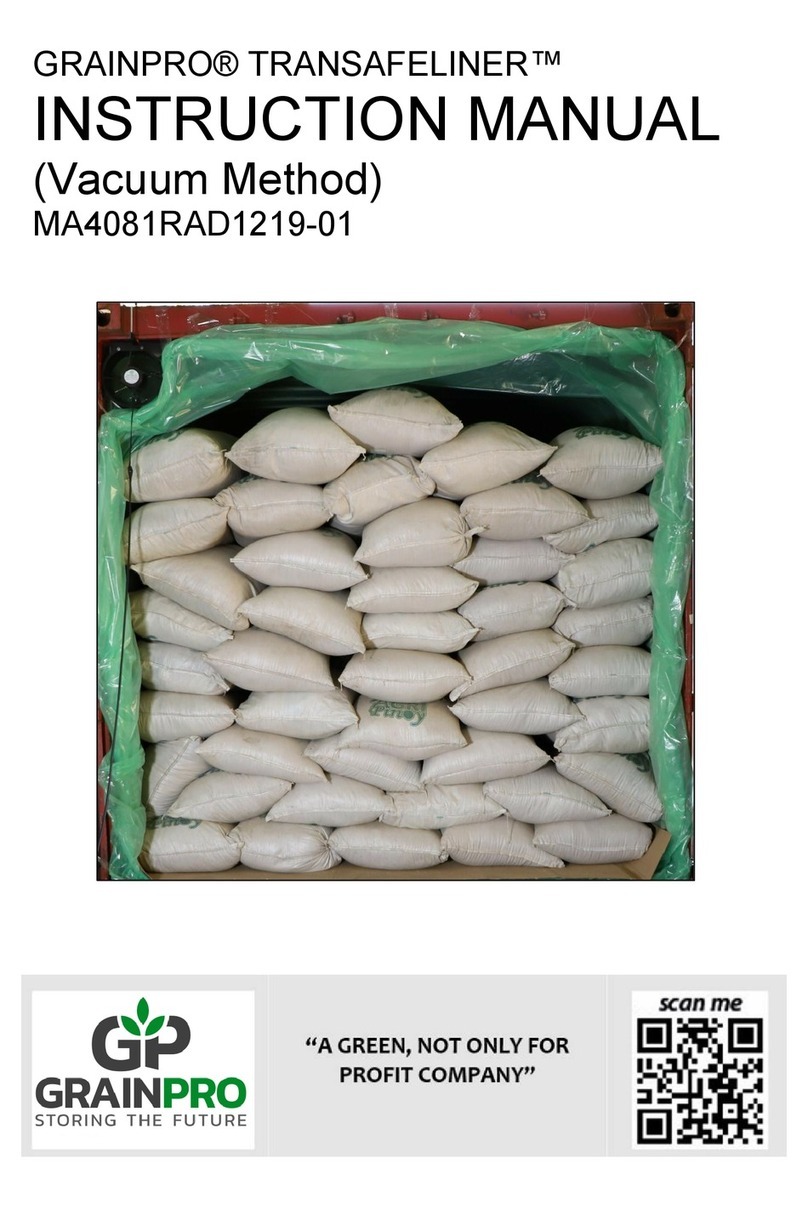

Horizontal Loading...............................................................................................................13

Vertical Loading ................................................................................................................... 14

Use of Desiccants/Dry Bags (Required)..............................................................................16

Plastic Valve Installation for Pressure Decay Test and CO2or O2Reading………..……………16

Sealing................................................................................................................................. 17

Pressure (Vacuum) Decay Test...........................................................................................18

Installing the Flexible Adapter Hose for CO2or O2Reading ............................................... 20

Using Oxygen Analyzer for Monitoring (Without CO2Flushing) - Optional ........................20

Using Carbon Dioxide Analyzer for Monitoring (Without CO2Flushing) - Optional............. 21

Carbon Dioxide (CO2) Safety............................................................................................... 21

Procedure for Purging with Carbon Dioxide (CO2) …………………………………………..…………22

Using Oxygen Analyzer for Monitoring (With CO2Flushing) - Optional ............................. 24

Using Carbon Dioxide Analyzer for Monitoring (With CO2Flushing) - Optional.................. 25

Closing and Opening the Container Van.............................................................................26

9. MAINTENANCE AND CARE .................................................................................................... 26

Repairing Punctures and Other Damages...........................................................................26

Recycling ............................................................................................................................. 26

10. FREQUENTLY ASKED QUESTIONS ...................................................................................... 26

11. WARRANTY CLAUSE..............................................................................................................27