10in. LASER GUIDE COMPOUND

MITER SAW OWNER’S MANUAL

10in. LASER GUIDE COMPOUND

MITER SAW OWNER’S MANUAL

10in. LASER GUIDE COMPOUND

MITER SAW OWNER’S MANUAL

GENERAL SAFETY WARNINGS AND PRECAUTIONS

• Keep the work area clean and dry. Damp or wet work areas

will lead injuries.

• Keep children away from the work area. Do not allow

children to operate this product.

• Store idle equipment. When not in use, tools and

equipment should be stored in a dry location to inhibit rust.

Always lock up tools and equipment and keep them out of

the reach of children.

• Do not use this product if under the influence of alcohol or

drugs. Read warning labels on prescriptions to determine if

your judgment or reflexes are impaired while taking drugs. If

there is any doubt, do not attempt to use this product.

• Dress properly. Do not wear loose clothing or jewelry.

Contain long hair. Keep your hair, clothing, and gloves away

from moving parts. Loose clothes, jewelry or long hair can be

caught in moving parts.

• Avoid accidental starting. Be sure the switch is OFF before

plugging in the tool. Carrying tools with your finger on the

switch or plugging in tools that have the switch ON invites

accidents.

• Remove all adjusting keys and wrenches. Make a habit of

checking that the adjusting keys and wrenches are removed

from the tool before turning it on.

• Do not overreach. Keep proper footing and balance at all

times. Proper footing and balance allows for better control of

the tool in unexpected situations.

• Use safety equipment. Eye protection should be worn at all

times when operating this machine. Use NIOSH approved

safety glasses. Everyday eyeglasses only have impact

resistance lenses. They are NOT safety glasses. A dust mask,

respirator, non-skid safety shoes, a hard hat, or hearing

protection must be used in appropriate conditions.

• Industrial applications must follow OSHA requirements.

• Stay alert. Watch what you are doing at all times. Use

common sense. Do not use this product when you are tired

or distracted from the job at hand.

• Check for damaged parts. Before using this product,

carefully check to ensure that the saw will operate properly

and perform its intended function. Check for damaged parts

and any other conditions that may affect the operation of this

product. Replace or repair damaged or worn parts

immediately.

• Replacement parts and accessories. When servicing, use

only approved replacement parts. Only use accessories

intended for use with this product. Approved accessories are

available from northern tool.

• Maintain this product with care. Keep this product clean

and dry, and keep the Saw Blades clean and sharp for better

and safer performance.

• For your safety, service and maintenance should be

2 of 9

performed regularly by a qualified technician.

• Use the right product for the right job. There are certain

applications for which this product was designed. Do not use

small equipment, tools or attachments to do the work of

larger industrial equipment, tools or attachments.

• Do not use this product for a purpose for which it was not

intended.

• Avoid exposure. Laser radiation is emitted from the laser.

Hazardous electromagnetic radiation is emitted from the

laser. Do not stare into the beam.

ELECTRICAL SAFETY

• Ground this product. The electrical power cord for this

product is equipped with a 2-prong plug. Never modify the

plug in any way. Do not use adapter plugs with this product.

When in use, make sure this product is always plugged into a

grounded electrical receptacle with an appropriate breaker

switch.

• Make sure the power switch is in the “off” position before

plugging in the power cord.

• Do not abuse the power cord. Do not use the cord to pull

the 2-prong plug from the power outlet. Keep the cord away

from heat, oil, sharp edges and moving parts. Replace a

damaged cord immediately. Route the power cord safely.

Protect it from being damaged by other equipment in the

shop. Do not route the cord where it can be walked on or

tripped over.

• To avoid accidental electric shock, do not let your body

come in contact with grounded surfaces such as pipes,

radiators, ranges and refrigerators.

• If you use an extension cord, make sure to use only

UL-approved cords having the correct gauge and length (see

chart a).

CHART A

PRODUCT-SPECIFIC SAFETY

• Place the Miter Saw on a flat, level and stable surface

capable of supporting the weight of the miter saw and the

weight of workpiece that will be cut.

• Maintain a safe work environment. Do not use this product

on or near damp or wet areas. Do not expose this product to

rain. Make sure there is adequate surrounding workspace.

Use this product in a well-ventilated area.

• Do not operate this product in the presence of flammable

liquids, gases or dust.

• Do not force the equipment. This product will do the work

better and safer at the speed and capacity for which it was

designed.

• Keep all guards in place and in working order. Do not

operate without the guard in place.

• Remove all adjusting wrenches from the product before

turning on the Miter Saw.

• Make sure that when installing the Saw Blade the saw

teeth point away from your body and toward the rear of the

miter saw.

• Avoid unintentional starting. Make sure you are prepared to

begin work before turning the saw on.

• Do not use this product for cutting metals, brittle, or

dangerous materials, such as asbestos, which can cause

harmful dust or vapors.

CAUTION: Some woods contain preservatives such

as copper chromium arsenate (CCA) that can be toxic. When

cutting these materials extra care should be taken to avoid

inhalation and minimize skin contact.

• Before using the miter saw, make sure the Saw Blade is

properly mounted on the saw spindle. Make sure the Saw

Blade is balanced, and is not bent or cracked.

• Allow the Saw Blade to reach full speed before feeding

wood into it. When turning it off, allow the Saw Blade to spin

down and stop on its own. Do not press against the Saw

Blade to stop it.

• Do not force the Saw Blade into the workpiece being cut.

Apply moderate pressure, allowing the Saw Blade to cut

without being forced.

• Never attempt to remove material stuck in the moving

parts of the miter saw while the saw is plugged in and

running.

• The Saw Blade will become hot while cutting. Allow the

Saw Blade to completely cool before touching.

• Whenever possible, use clamps or other safe, practical

ways to hold and support the workpiece.

• Always disconnect the saw from its electrical supply

source before leaving the work area, moving the product

from one location to another, changing the Saw Blade or

cleaning sawdust from the unit.

• Never reach around saw. Keep hands out of path of saw

blade. Never reach in back of the fence.

UNPACKING

When unpacking, check to make sure that all the parts shown

on the Parts List and Diagram are included. If any parts are

missing or broken, please call Northern Tool & Equipment at

the number shown in this manual as soon as possible.

OPERATING INSTRUCTIONS

NOTE: All parts below refer to the parts listed in this manual.

HOW TO TRANSPORT THE COMPOUND MITER SAW

1. The Compound Miter Saw is portable, and can easily be

moved to the worksite.

3 of 9

2. Unplug the saw from the power source.

3. Hold the handle down to make sure the blade touches the

slot of the Kerf Board (#45), then pull out the lock pin

assembly (#55-58) and turn it clock-wise 90 degree before

securing it. Release the handle. The cutting head should lift

on its own.

4. Wrap up the power cord.

5. Take away the Supporting Brackets (#6) on the sides of

the Base (#4) and then take hold of the sides of the Base

(#4), and lean the saw slightly against the body.

WARNING:The lock pin is for moving and storing

and is not to be used for any cutting operations.

NOTE: Do not carry the saw by the Handle, as this can cause

damage to the unit.

HOW TO ASSEMBLE THE ACCESSORIES

WARNING:The saw must be unplugged before

adding or removing any accessories.

1. The Compound Miter Saw comes with several accessories

you may wish to attach to the unit.

2. The Vise Jaw (part #7-12) can be inserted into the hole on

either side of the worktable (part #23) and locked in place

with the Adjusting Handle (part #12). (We recommend you

insert on the left side of the plate. As the motor will touch the

Vise Jaw if you insert the Vise Jaw on the right side of plate.)

3. Insert the Supporting Brackets (#6) to the holes on the

base (#4). Lock the bracket with Butterfly Screw (#27). Slide

the Plastic Stopper (part #32) onto one of the Supporting

Bracket (part #6).

HOW TO MOUNT THE COMPOUND MITER SAW

1. When in use, the saw should be securely mounted to a flat,

level, stable table or workbench capable of supporting the

weight of the saw, accessories, and the workpiece being

cut.

2. There are two 1/4in. mounting holes on the rear side of the

Base (part #4). Using the two mounting holes on the saw

base as a template, mark the two 1/4in. holes on the table or

workbench that are to be drilled through. Drill the holes and

secure the saw to the table or workbench, using two 1/4in.

bolts, lock washers, and nuts (not provided)

3. Use two C-clamps (not provided) to secure the front side

of the Base (part #4) to the table or workbench.

HOW TO INSTALL OR REPLACING THE SAW BLADE

1. WARNING! Prior to performing any assembly and/ or

adjustment procedures, make sure the power cord of the

Miter Saw is unplugged from its electrical outlet. Make sure

the unit has completely cooled, and wear heavy-duty work

gloves.

2. When replacing the saw blade, make sure the new saw

blade has a diameter of 10in., an RPM rating of at least 4600,

and an arbor hole of 5/8in. or 1in. diameter. The arbor hole

can be switched to 1in. by adding the adjusting ring(part

#107). Also the new saw blade should be suitable for the

type of workpiece being cut. Abrasive cutoff wheels cannot

be used with this saw.

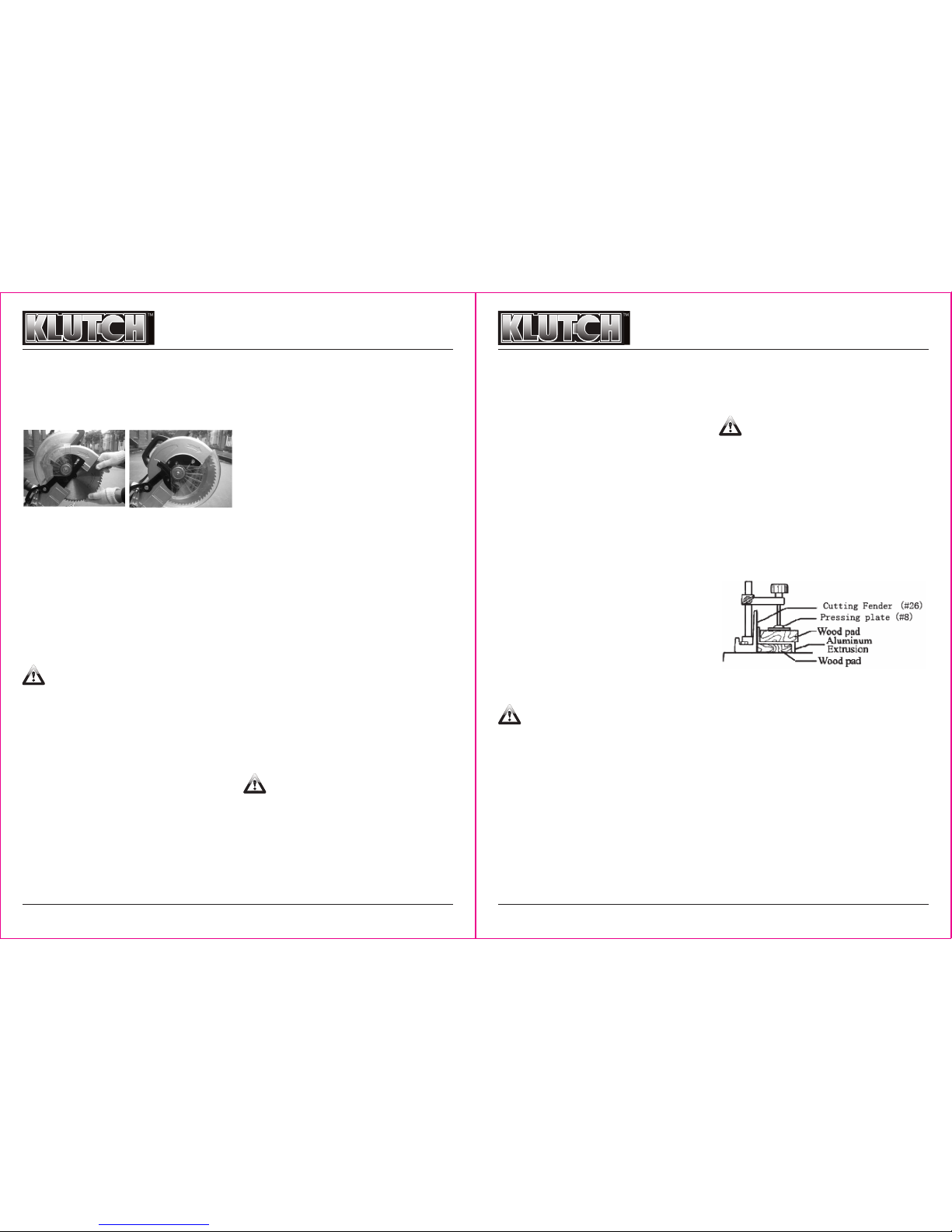

3. Lock the saw blade in its upward position. To do so, pull

out the Lock Pin Assembly (#55-58) and turn it clockwise

90°before securing it. (Figure A)

4. Loosen the Triangle Bolt (#78) that holds the Fasten Plate

(#77) in place (Figure B). Then remove the Bolt (#81) (Figure

C). Do not loosen the two Bolts (#80) (Figure D).

5. Depress the Rotor Clamp Assembly to keep the saw blade

from turning. (Figure E)

6. Using the Hex Sleeve Spanner (#161), remove the Arbor

Fasten Bolt (#74), the Arbor Flat Washer (#73) and Outer

Flange (#72) which are connected with the Arbor (#112)

NOTE: Remove the Arbor Fasten Bolt (#74) by turning it

CLOCKWISE. (Figure F)

Lock Pin Assembly (#55-58)